Installation of a film underfloor heating is carried out to improve the comfort of staying in the room, as well as in addition to the already functioning autonomous or industrial heating. Electric heaters of this type are classified as indirect infrared systems. Installation of products is quite simple, but has a number of nuances that affect the process of laying the subsequent finish. In order not to make a mistake when choosing a model and its connection, you should study the range of products on the market and the operating rules.

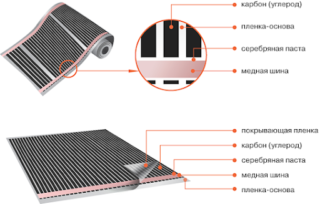

The device of a film heat-insulated floor

The film heater is a relatively simple design. The basis is a heat-resistant polypropylene fabric into which the heating elements are fused. Their role is played by carbon strips, to which copper conductive wires are connected.

When electricity is supplied, carbon fragments begin to emit infrared waves, under the influence of which objects and objects are heated. The wiring is made in a parallel way, which eliminates the failure of the product in case of failure of one element in the circuit.

Advantages and disadvantages

When choosing an additional heating system, it is necessary to analyze a number of nuances relating to all aspects inherent in a particular material.

When choosing an additional heating system, it is necessary to analyze a number of nuances relating to all aspects inherent in a particular material.

Connecting a film underfloor heating gives property owners the following benefits:

- profitability;

- ease of installation;

- lack of electromagnetic radiation;

- there is no need to do a heavy screed;

- microscopic thickness;

- optimal wiring diagram;

- uniform heating of the surface;

- durability;

- Large selection of topcoats.

Products have their inherent disadvantages:

- high cost of products from trusted manufacturers;

- low adhesion to adhesives;

- static and overheating when interior items are on top;

- low resistance to pressure and stretching.

If you connect an infrared film floor heating in a large area, you need to be prepared for high electricity bills, since with a coverage of 15 m² its consumption will be 20-25 kW per day.

Specifications

A film floor is produced in the form of strips with a width of 50-100 cm and a total length of up to 50 m. Cutting into fragments of the desired length is carried out according to the marks applied to the material. Depending on the manufacturer’s company and model, the strip thickness is 0.25-0.48 mm with a power consumption of 25-35 kW / h per linear meter.

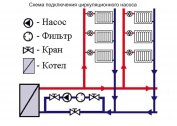

To connect the assembled tape floor to the circuit, a multicore copper cable of type PV3 with a cross section of 1.5–2.5 mm² is used.

Depending on the power consumption, the following wires are used:

- 1.5 mm² - 4.0 kW;

- 2.0 mm² - 6.0 kW;

- 2.5 mm² - from 6.1 kW;

Infrared underfloor heating can be laid under a laminate, linoleum, ceramic tiles and even under a wooden parquet made of dense types of wood.

Application area

Before deciding on the purchase and installation of an infrared film floor, you should understand how this event will be useful in terms of financial investments and the subsequent effect.

Systems are used for such purposes:

- Heated small detached buildings. Since it is impossible to bring central heating and a gas line to them, the heating film is an excellent way out of this situation at low installation and maintenance costs.

- Creating comfortable conditions in city apartments. Typically, corridors, kitchens, bathrooms and loggias are tiled. The material is cold to the touch even in the summer. Installation of underfloor heating will make life more pleasant and eliminate the risk of diseases from walking on an icy tile.

- Back-up heating. It is used in the off-season when utilities have already stopped or have not yet begun to supply hot water to the system. If there is a double-circuit boiler, the IR system is switched on for the period of its repair, maintenance or replacement.

An investment in a film heating installation is a promising and optimal measure in all respects.

Mounting technology

If you install the infrared warm floor with your own hands, you can save on the services of specialists, which are quite expensive.

If you install the infrared warm floor with your own hands, you can save on the services of specialists, which are quite expensive.

Installation technology is a sequential process consisting of the following steps:

- Designing a project. First, measurements are taken, and then a diagram is drawn up. When the film is installed as the main source of heating, it is necessary to cover the entire open area. When the goal is to heat individual sections, it is planned to lay strips in the middle of the room. Please note that the edges of the paintings should not be closer than 20 cm from the walls and radiators.

- Laying a heat-insulating layer. First, the base is treated with an antiseptic and a primer, then a foil-coated heat-reflecting substrate is laid on it. The material goes from wall to wall, the joints are glued with aluminum tape. The reflective surface will allow the warm floor to work more efficiently without spending energy on heating the floor slab.

- Drawing a marking. It is done in accordance with the previously drawn up scheme. It is necessary to place the film so that it is a continuous canvas, but without overlays at the edges.

- Laying heating strips. First you need to figure out which side to put the film floor on. This is done with carbon fragments up, and copper cores down. Fragments must be mounted so that there are no bare wires left. The connection is carried out using clamping sleeves with their subsequent filling with silicone. The protruding joints are recessed in the substrate. For this, recesses corresponding to the size are cut out in it.

- Connecting and connecting the power cable and thermostat. It is advisable to wrap the cable in a shtroba, and the regulator in an internal mounting box (socket box). If this is not possible, an external plastic box is used. Then, the inclusion and verification of the performance of the film floor is carried out.

The final phase of installation is the laying of the finish coating. Boards, laminate, tile and parquet are laid immediately on the heater. For linoleum and carpet, an intermediate layer of plywood or OSB is made.

Top brands and manufacturers

According to user reviews, the best operational characteristics are the products of such manufacturers:

- HeatPlus;

- Caleo Gold;

- RexVa;

- Q term;

- Monocrystal;

- EASTEC Energy.

The leading positions are occupied by goods from the USA, Germany and South Korea. It is recommended to purchase a film floor at certified retail outlets after studying the documents that the goods are genuine.