There are a large number of different heating systems, but not all of them can be implemented in a private house. If financial difficulties do not allow to install and use electrical equipment, and the main gas pipeline is located far from the structure, a diesel heating boiler will be the best solution.

Advantages and disadvantages of diesel heating boilers

A diesel fuel boiler has many advantages, which determines its relevance.

- High coefficient of performance (COP). When burning diesel fuel, a large amount of heat is released. The efficiency of diesel boilers is only slightly inferior to gas boilers in their performance.

- Low power consumption. Unlike electric diesel boilers, a small amount of electricity is required for operation. It is necessary only for the operation of control and safety automation, circulation and fuel pumps. Due to this feature, diesel boilers can be used in places where there are problems with the release of electric power to the house.

- Low fire and explosion hazard. Diesel fuel is less dangerous than liquefied or main gas. For installation, special permissions are not required, the requirements for the room are minimal.

- A wide range of models. Coppers in diesel fuel are produced for houses with any area. It is only necessary to correctly calculate the power of the equipment. As a rule, the formula is used for calculations: “1 kW per 10 sq. M.”

The main disadvantages of the equipment:

- High operating costs. Diesel fuel is in second place after electricity.

- The need for quality fuel. For year-round space heating, it is necessary to take care of concluding an agreement with a supplier of high-quality diesel fuel in advance. Otherwise, the owner will have to face problems: heat exchangers and other equipment parts become dirty, the burner starts to smoke, and the efficiency of the equipment decreases.

The operation of diesel boilers has one feature - the emission of unpleasant odors. To clean the air, you first need to take care of the organization of a natural and forced ventilation system.

Selection criteria for a private home

The range of diesel heating boilers is large, so choosing the most suitable model is not easy. Based on the following criteria: the number of circuits, the method of installation and removal of exhaust gases, power, type of fuel and cost.

If the heating system should exclusively heat the house, it is enough to purchase a single-circuit type. If you need to heat the premises and use hot water, it is better to give preference to dual-circuit heating equipment.

Power is calculated depending on the area of the heated room. When making calculations, it is important to consider all heat conductors - the material of walls, floors, windows and doors. For help, you can contact the engineers or use special calculators.

Diesel boilers on the market are divided into three main price groups: cheap - Russian-made; medium in price, but with good quality - production Slovakia, Japan, Czech Republic, Spain, South Korea and Italy; expensive and high-quality - made in Germany, Sweden.

Types of diesel boilers for heating

The diesel heating boiler is classified into several types according to its main characteristics: heat exchanger material and type of burner.

Burners are divided into three types:

- Modulated are the most profitable and efficient designs, their characteristic feature is the regulation of their performance from 10% to 100%, based on the required heating temperature.

- Single-stage - the least effective, but at the same time budget models. They work continuously, therefore, to adjust the temperature and change the power you have to completely shut off the boiler.

- Two-stage configurations are able to work in two modes - at 40% and 100% of the base performance. Thanks to this, it is possible to save a little fuel consumption for heating the building.

Heat exchangers, in turn, are divided into two varieties:

- Steel models are easy to maintain and have an affordable cost, but at the same time they are characterized by low resistance to corrosion and condensation.

- Cast iron heat exchangers are heavy, high cost and susceptible to overheating, but have high corrosion resistance.

The performance and efficiency of the heating system, as well as the price, will depend on the materials used.

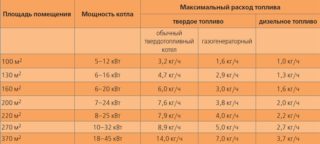

Fuel consumption calculation

To calculate the required amount of fuel, you need to know three parameters - efficiency, power and serviced area. In calculations, the ratio is traditionally used:

- A standard burner that runs at full capacity burns about 24 liters of fuel within 24 hours.

- 10 kW of energy is usually enough to heat 100 sq.m.

- When 1 liter of liquid fuel is burned, about 10 kW of thermal energy is released.

For every 1 sq.m. when the burner is operating at maximum power, about 0.24 liters of fuel are needed. Knowing the average ratio, you can calculate the cost of fuel for one heating season for a house with a certain area.

The diesel heating system represents a worthy alternative to gas, wood and even electric heating in a private house. The main task of homeowners is to thoroughly approach the selection of equipment.