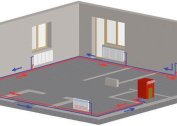

It is customary to approach the selection of components and spare parts for underfloor heating with special attention, since the quality of assembly and maintenance of the heating system depends on its thoroughness. By purchasing the necessary components for this, first of all, they are convinced of the availability of a certificate for each individual part. Such prudence will eliminate the troubles associated with the purchase of fakes and counterfeit products. Further, the main components for a water floor heating are considered separately for each position.

Draft screed and damping tape

The main requirement, which is necessarily observed when arranging a warm floor, is to obtain an absolutely flat surface, simplifying the procedure for laying plastic pipes. If this condition is violated at least a little, the user will have to level the floor, using the initial screed for this.

During these operations, auxiliary components will be required.

Damper tape is needed to compensate for the thermal gaps that occur in the floor screed. Its use will significantly increase the quality of pipe laying and extend the life of the entire system.

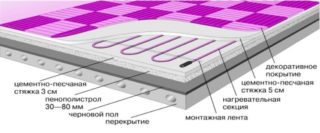

Thermal insulation

Thermal insulation of a floor water system is necessary to reduce the level of heat loss. If it is available, the heat given off by the pipes is reflected upward towards the heated room. When choosing the appropriate type of insulation, special attention is paid to rooms on the ground floor with cold ground or an unheated underground located under them.

The Russian sales market presents a lot of materials for underfloor heating. Here you can find ready-made heat-insulating mats intended directly for laying the structure on a previously prepared base. They have different thicknesses and have sufficient strength with relatively low weight. Their working surface is made in the form of a special relief, which makes it easy to lay and fix pipes in special recesses.

The use of components that have a high cost will only slightly affect the final price of the entire structure. This is due to the fact that insulating mats contain, in addition to the heat-insulating layer, waterproofing, reinforcing mesh and special fasteners. Pipes mounted according to the selected scheme are fixed on their surface with special bosses that are included in the package of finished products.

Waterproofing and reinforcing mesh

The use of waterproofing during the installation of water heated floors is not considered mandatory. But to do it all the same does not hurt, it will take quite a bit of effort. It is necessary to lay on top of the insulation a layer of plastic film, laid with a slight bend on the walls (about 15-20 cm).

The use of waterproofing during the installation of water heated floors is not considered mandatory. But to do it all the same does not hurt, it will take quite a bit of effort. It is necessary to lay on top of the insulation a layer of plastic film, laid with a slight bend on the walls (about 15-20 cm).

If necessary, you can increase the waterproofing, laying one on top of several layers of film with a small overlap. The joints are then glued with construction tape.

A reinforcing mesh of wire is used to strengthen the body of the screed and at the same time provide the ability to attach water pipes. The step of laying the latter directly depends on the size of the mesh cell, which is desirable to choose a smaller one - 150x150 mm with a wire cross section of 4-5 mm. If mats with a relief structure are used for thermal insulation, there is no need for reinforcement.

Water pipes and fasteners

The pipes used in the heating system differ in material and in their main technical indicator - diameter. The optimal size is selected in each case, especially, as a rule, does not exceed 18-20 mm. When choosing the material from which the pipe products themselves are made, they proceed from their reliability and cost.

The most suitable for underfloor heating are pipes made of cross-linked polyethylene (RE-X). A special processing method (crosslinking) used in their manufacture contributes to the formation of additional bonds between individual polymer molecules. Thanks to this, finished products acquire the necessary strength and heat resistance - they are able to withstand operating temperatures up to 125 ° C.

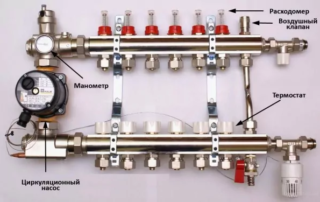

Manifold with all accessories, pump and boiler

Before buying a warm floor, first of all make sure that there is a collector in its kit, which usually includes the following items:

- fitting;

- shut-off valves;

- air outlet;

- drainage tap and automation elements (including thermostat).

Before buying, check the availability of a circulation pump in the equipment set, which guarantees the continuity of the movement of the coolant in the heating system. Its obligatory element, heating the water carrier to a certain temperature, is a gas or electricity boiler.

Screed materials

After installing the pipes, a finishing screed is poured on top. To prepare solutions in both cases, it is preferable to use a ready-made building mixture intended for arranging warm floors.

Another option that allows you to get a good result is as follows: the usual working mixture, made on the basis of cement and sand (in a classical ratio of 1: 3) is mixed, special plasticizers are added to it, after which the resulting composition is thoroughly mixed.

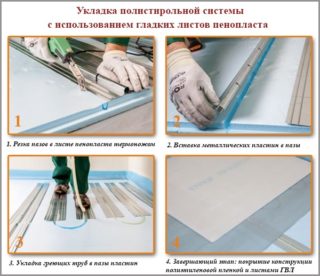

Materials for the dry method of arranging TP

If it is not possible to fill the screed under the water floors with conventional methods, it is allowed to use the dry method. To equip the base according to this method, the following materials will be required:

If it is not possible to fill the screed under the water floors with conventional methods, it is allowed to use the dry method. To equip the base according to this method, the following materials will be required:

- a set of heat-reflecting metal plates with grooves for HDPE pipes;

- a set of fasteners that securely fix pipe blanks in grooves;

- the pre-calculated number of sheets of gypsum fiber used as a finish (finish) coating.

The application of this technique significantly increases the speed of installation of warm floors, but its reliability is somewhat inferior to the traditional approach. The cost of components in this case will be significantly higher.