Various insulating materials are used to warm structures. Some of them are applied recently. During installation, it is important to lay the foil insulation correctly in order to achieve maximum heat transfer.

Varieties of foil insulation

The material has several varieties. They differ in the components used, but all have a layer of foil. The characteristics of the species are slightly different, so each of them is used in certain conditions.

Foamed polyethylene with foil

Available in rolls, one side covered with aluminum foil. The thickness of the insulation is 2-10 mm. The bottom layer is made on the adhesive. The basis is a layer of foam with various indicators of density, thickness and structure.

Technical characteristics of the material allow its use in a variety of fields.

- It is possible to work with a heater at a temperature from -40 to +120 degrees.

- Noise absorption - up to 32 dB. This makes it possible to use as sound insulation.

- Available in white rolls in standard sizes 1 m wide and 50 m long.

- The compression limit is 0.035 MPa.

- Thermal conductivity - 0.037-0.038 W / m * K.

The material is available in various versions, which are indicated by letter marking. Foiled foamed polyethylene allows you to protect your home from cold, noise and dampness.

Folgoizol

The insulator is made on the basis of bitumen with polymeric materials or rubber. On top of the foil isol is covered with foil, which enhances the wear resistance and durability. It is used for roofing, waterproofing. Available in two versions: fused and self-adhesive foil isol. It has the following specifications:

- roll width - 1 m, length - 10 m;

- absolute water tightness;

- the bottom layer is a polymer film;

- basis - fiberglass, fiberglass, bitumen, polyester;

- top coating - aluminum foil;

- resistance to chemical products;

- long term of operation - 80 years.

Due to the versatility and simplicity of processing foil is used in construction, in medicine, food industry, engineering.

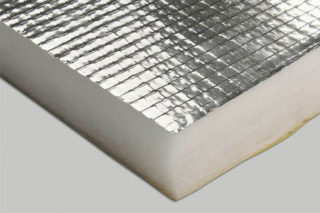

Mineral wool rolls

Mineral wool is used to warm the surface, produced in rolls, plates, cylinders, covered with foil on one side. Thickness can vary from 50 to 100 mm. The main advantage of cotton wool is that it hardly conducts heat. Low thermal conductivity - 0.03-0.04 W / m * K allows you to use the material in all types of insulation work.

Basalt lamellar heaters

The basis of this unique insulation is spent rocks, therefore it is also called stone wool. Basalt material has several main features.

- The structure of the insulator allows you to store heat in the room.

- Unlike other types of insulation, it does not absorb water at all. It is recommended for warming rooms with high humidity.

- Does not interfere with the passage of steam.

- It has good fire resistance. Material refers to non-combustible substances. The melting temperature of basalt is +1114 degrees, so it can be used as an insulator for devices operating at elevated temperatures.

- Provides a high level of sound insulation.

- The heat insulator has high strength and density, is not subject to deformation, and serves for a long time.

- Resistant to mildew, rust, chemicals.

Lamellar basalt insulation has a self-adhesive layer of foil.

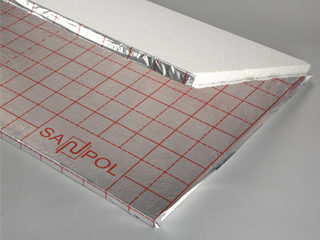

Polystyrene foam boards

Expanded polystyrene heat insulator is used in industrial construction. Features of the material are as follows:

- low cost - an equivalent volume of mineral wool is twice as expensive, it will need more than a polystyrene foam to warm a house;

- insulation boards are easy to install;

- universal application - for wooden, concrete and brick surfaces, foundations, floors, loggias and balconies, sound insulation, insulation.

In order to correctly put the insulation with foil on the floor or on the walls, you need to familiarize yourself with the recommendations for installing the material.

Technical advantages

The foil layer reflects heat inside the room so that it does not go out.

Advantages of the material:

- thermal insulation of foil insulation reaches 95%;

- the material does not leak water;

- protection of the room from wind, drafts, temperature difference;

- the presence of foil improves sound insulation;

- the material is environmentally friendly, safe for humans and the environment, does not emit harmful substances;

- protects walls and floors from rotting, moisture, damage by rodents;

- performs a mirror image of the heat in the room, since the insulation with foil must be laid with the foil side up.

The advantages of the material make it possible to use it in almost any type of building, for warming private houses, hydro and sound insulation.

Rules for laying foil insulation

There are rules for laying thermal insulation with foil.

- Parameters of foamed polyethylene allow you to leave unchanged the amount of living space. You can lay the material using a simple construction stapler.

- Laying foil insulation on the floor is necessary so that the aluminum side of the material is located to the inside of the room.

- Basalt wool is placed with a layer of foil up. You need to work with this material in special protective clothing and a respirator, since it releases substances harmful to humans. For convenience, basalt is sawn into lamellas (strips) of the desired width.

- Fixing polystyrene boards on the floor is important in the right direction. They are laid under linoleum tightly to each other. The foil provides a tight seal.

Each type of material is fixed with the foil side inside the room. If the insulation is laid incorrectly, most of its characteristics will become useless.

The use of foil insulation

The use of materials depends on their technical features.

- The made foam polyethylene is universal. It can be used for insulation of walls and floors, sound insulation.

- Folgoizol is used in construction, pipe and roof insulation.

- Foil mineral wool is used for insulation and heat preservation of walls, floors. Unlike ordinary mineral wool, foil does not allow moisture to penetrate inside the fibers.

- Basalt insulation is considered the most highly effective, since it is not exposed to moisture, fire, temperature extremes. It is used to isolate different objects.

- Expanded polystyrene plates insulate the floor.

All materials coated with aluminum foil have high technical characteristics.

The nuances of mounting and mounting

Installation of insulation is simple, it is easy to cut and fit. Work outside and inside almost do not differ from each other.

The main nuances:

- the surface on which the insulation is laid must be clean;

- the material is straightened so that it is even, without wrinkles;

- the foil prevents the release of heat, so it is laid with the outer side up;

- the insulator is glued butt, the joints are glued with tape;

- if the insulation does not have a self-adhesive layer, use special glue.

It is important that the adhesive used for fastening does not emit harmful substances and firmly holds the material.

Walls

Installation of insulation to the wall should be thoroughly thought out. An air gap is left between the material and the subsequent finish to prevent condensation.

- The membrane is fixed, an insulator is rolled over it.

- The material is fixed with slats. Their thickness should be greater than the main insulation.

- Along the edges of the rails connect the insulator with brackets.

- Panels are made on top of the rails, their thickness provides the necessary air gap.

When insulating with mineral wool, the film is laid to prevent the ingress of steam and moisture inside.

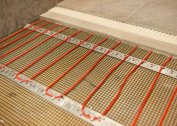

Floor

Warm floor, regardless of whether the wooden base or concrete, do the same.

- They clean the floor from debris before applying insulation.

- Coat the base with a primer.

- After drying, roll out the insulation. Strip overlap, fasten with construction tape. Under the linoleum, you can decompose the substrate, which will make the floor much warmer.

- A top coat is applied to the insulating material from above.

If the installation of a warm floor is provided, the insulation must be laid with the reflecting side up, then the reinforcing mesh, heating elements and the finish lining.

The choice of insulation materials is wide enough. Each of them has distinctive characteristics. Application depends on which room needs to be insulated.