A complete set of any heating system must necessarily include control devices. Without them, the heat supply will be inefficient, which will lead to an increase in current costs. One of the most popular devices is the temperature controller for the heating system: the principle of operation, installation, the device must be known to draw up a competent diagram.

Appointment of temperature controllers for heat supply

First of all, you should decide on the purpose of these devices. The fundamental principle of operation of a heating thermostat is to limit the flow of coolant to a specific section of the system - a pipeline, radiator or battery.

Despite the fact that the programmable thermostat for the heating system differs from the mechanical counterpart - in order to perform its functions, both apply the principle of changing the pipe bore. A shutter or a needle valve is used for this. The function of regulating the position of these components is performed by the control element. It can be either mechanical or electronic.

By installing a thermostat for a heating battery or a similar device for a boiler or collector, the following improvements in the operation of heat supply can be achieved:

- The ability to adjust the flow of coolant into the battery or heating circuit. Thus, it is possible to control the degree of air heating in each room of the house;

- Cost optimization. If you install them on all critical parts of the system - you can achieve savings of 25-30%;

- Work automation. This is especially true for innovative methods of heat supply. It is mandatory to install a thermostat for air heating on each damper to control the flow of hot air.

However, there are certain restrictions on the use of these devices. Experts do not recommend the use of a temperature regulator for a heating boiler, as it will limit the flow of heat transfer to the entire system. It is best to install several appliances on the batteries, pump and collector.

Each thermostat for heating radiators has a bandwidth parameter. It depends on the diameter of the connecting pipe. In the open state, the temperature regulator should not restrict the flow of the coolant, creating excessive hydraulic resistance.

Types of heating thermostats

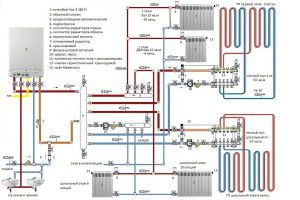

At the first stage, it is necessary to calculate the main characteristics of the system. Then, based on the received data, a layout of control devices is compiled. So, the thermostat for a two-pipe heating system is mounted on radiators. In addition, installation on tee branches is possible.

Can a thermostat for central heating differ from a similar one for autonomous heating? There is no difference in models. The choice is determined only by the device parameters and design features. Therefore, before purchasing it is necessary to solve the following problems for yourself:

- Instrument Installation Location. Thermostats for heating pumps are structurally and functionally different from those for batteries. They have a large degree of adjustment, as well as the ability to connect to the pump control unit;

- Required Functionality - work in automatic, manual or semi-automatic mode;

- Adaptation to a common heating control system. To do this, the heating thermostat must have plug-in terminals for connection to a central programmer or similar device.

Currently, manufacturers offer several types of temperature controllers. They differ not only in appearance, but also in structural and functional features. Consider the most common types of these heating control devices.

Before purchasing a thermostat for a heating battery, it is recommended that you read the connection instructions. Not all models are designed for installation in a piping of a cast-iron or bimetallic radiator.

Mechanical heating thermostats

To complete the budget heating system, the best option would be to install mechanical models of temperature controllers. They are distinguished by simplicity of design, simple installation. However, along with these qualities, mechanical thermostats for water heating have several features of installation and operation.

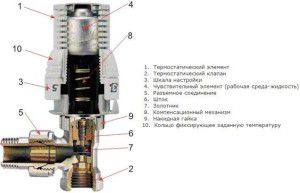

Structurally, this device consists of a locking mechanism (needle valve) and a thermal head. In the latter is a sensitive element that expands under the influence of high temperature. It presses on the valve seat, which leads to a partial or complete blockage of the coolant inflow. To set the upper and lower limits of the operation of the thermostat for heating radiators, a spring is provided in the design that connects the thermostatic element and the control head. The operating conditions of the device depend on the set compression ratio.

Features of the operation of mechanical thermostats are as follows:

- Full autonomy. The device does not need to be connected to the power supply;

- Semi-automatic mode of operation. It is enough to set the temperature of the thermostat for central heating once;

- Affordable cost. The price of budget models ranges from 200 to 400 rubles.

The disadvantages include frequent damage. This is especially true for the operation of a thermostatic element. Over time, the liquid loses its properties, which leads to improper functioning. After a long period of inactivity, scale may form between the valve seat and the thermostatic element. This is the reason for the failure of the thermostat for the two-pipe heating system.

During installation, the thermostatic head must be horizontal. Otherwise, hot air from the battery will affect it.

Electric heating thermostats

They are designed to operate electric heaters. The simplest temperature regulator for electric heating is an on / off relay, activated depending on the readings of the temperature sensor.

Such devices are part of electric heaters and perform an important function. Without them, the heating element will work continuously, which will lead not only to a significant increase in temperature, but will increase energy costs. In this case, the installation of the thermostat on the heating radiator is carried out in the factory. But there are options for self-manufacturing of this device and installing it in an electric heater.

Features of the operation and operation of electric temperature controllers:

- Automatic control of the degree of heating of the device and turning off the electric heating element when the optimum temperature is reached. For this, a temperature sensor is built into the design;

- Ensuring work safety;

- Some models may have a programmable thermostat for the heating system.After specifying the operating modes, it is possible to achieve automatic functioning of the device depending on the time of day, outdoor temperature in the room and indoors.

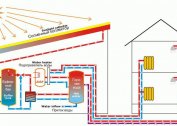

Thermostats for air heating work on a similar principle. But they control the position of the hot air damper.

To connect an electric heater, it is recommended to select a separate power line connected directly to the central distribution panel.

Electronic heating thermostats

These are complex heating control devices, the operation of which is carried out using a microprocessor. It connects to external temperature sensors and has a flexible software package.

The difference between this device, electric thermostats for electric heating and mechanical models is a much greater functionality. Depending on the type of device, it may have terminals for connecting external devices, as well as switching with other control components. In particular, with a programmer.

Almost all electronic thermostats for heating differ in the ability to control the heat supply. Some have only a built-in temperature sensor and a mechanical part responsible for the volume of coolant inflow. But most often, buyers stop at models with significantly greater capabilities:

- Remote control. For this, an electronic port is provided in the electronic temperature controller for a heating boiler or radiator, through which control signals are received;

- The ability to independently set a program of action depending on external conditions. Programmable thermostats for heating systems are convenient for intermittent stay in the house. You can configure the device so that it starts the heat supply at a certain time or by command from the GPS module;

- The mode of maintaining the minimum temperature of the coolant to provide freezing of water in the pipes. This feature will save costs.

Otherwise, the principle of operation of the electronic heating thermostat remains the same - changing the position of the valve (needle valve) using a control element.

Not every model can be connected to other devices. Some thermostats for heating pumps do not have external connected elements. This must be checked before purchase.

Installation of temperature controllers in the heating system

Before proceeding with the installation of control devices, it is necessary to check - are they suitable for this heating system? In some cases, you should first carry out a small upgrade, and only then proceed with installation.

The main principle of the correct installation of the thermostat on the heating radiator is the absence of the influence of the operation of the device on the heat supply parameters. Those. after its installation, throughput in this section of the circuit should not deteriorate, additional hydraulic resistance should occur, etc. This is especially true for a single pipe system.

In this case, you must perform the following steps:

- On the site where it is planned to install the thermostat for the heating radiator, a bypass is made. This is a pipe connecting two sections of the trunk to allow partial or complete redirection of the coolant movement to bypass the battery.

- Depending on the device of the heating thermostat, the place of its connection in the radiator, pump or collector is selected.

- The possibility of completely disconnecting the trunk section from the system without stopping circulation is checked.

These are mandatory installation requirements, which do not depend on the operating principles of thermostats for water heating.For proper installation, it is necessary to consider the features of connecting control devices to each heat supply element.

For normal heating operation, it is necessary to calculate the system parameters, taking into account the characteristics of thermostats for central heating or an autonomous analogue.

Installing the thermostat on the battery

The installation of a thermostat for water heating can be performed both at the top of the battery, and at the bottom. It all depends on how the device is connected to the system. After choosing the optimal model, you can proceed directly to the installation.

To do this, you need to follow simple rules:

- Accounting for the direction of movement of the coolant. This is important when installing thermostats for a two-pipe and one-pipe heating system. On the case of the control element, the arrow indicates the desired direction of movement of hot water;

- The mechanical part is mounted first, and then the thermal head. Its position should be such that the air regulator is not affected by hot air from heating radiators;

- The control element must not be covered with a decorative panel. This can lead to overheating and malfunctioning of the device.

Otherwise, experts recommend adhering to the recommendations on installing a temperature controller on a heat supply radiator from the manufacturer.

After installation, it is necessary to check the operation of the device in several modes, up to the complete opening and closing of the damper.

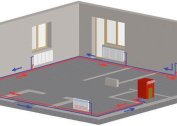

Temperature regulators in heating collectors

In the system of underfloor heating and collector heating, temperature controllers are an integral element. In this case, electronic models are used with the ability to connect to external temperature sensors.

In such schemes, it is important to choose the correct control devices for the flow of coolant. Modern electronic temperature controllers for a water heat-insulated floor are equipped with servo drives, which can quite smoothly regulate the volume of coolant inflow. However, for their correct installation, you will need to follow these rules:

- The bandwidth of the device should be no less than in the connected nozzles;

- For normal operation, it is recommended to install an uninterruptible power supply unit, since the circuit will not function when the power is turned off;

- Mandatory presence of a security group in the collector harness. Exceeding the temperature regime or pressure can adversely affect the state of the thermostat.

The best option is to purchase a fully equipped collector. All its elements will be coordinated with each other, which will present the risk of malfunctions.

The installation of mechanical temperature controllers for a water heated floor is not recommended, since their work cannot ensure the normal functioning of the system.

Installation of temperature controllers for heating circulation pumps and boilers is extremely rare. This is due to the fact that after installation, the device will affect the speed of the coolant. A small decrease in the passage in the main section is enough to cause excessive hydraulic resistance.

To improve the operation of the thermostat, it is recommended to install together with modern heating devices with low inertia - aluminum or bimetallic radiators.

The video shows an example of installing an electronic temperature controller: