The ability of a building to retain heat depends on the quality of thermal insulation of the ceiling surface. If the ceiling has not been insulated in the bath, the stove will not be able to quickly heat the air flows, and condensate will drip down. Using a step-by-step action plan, choosing the right materials, the owners will cope with the work in a short time.

The better to insulate the ceiling in the bath

Before choosing heat-insulating materials for a bath, you need to consider that in this room a lot of humidity and temperature are constantly maintained. High-quality insulation should have:

- resistance to temperature changes and humid environment;

- resistance to mold and insects;

- compatibility with other finishing materials;

- low moisture absorption;

- environmental cleanliness, so that the bath was normal to breathe;

- low thermal conductivity to prevent the penetration of cold air inside;

- ease of installation without loss of basic characteristics.

Choose materials that are light in weight for the bathhouse - they are easier to carry.

Mineral wool as a heater

Mineral wool, or basalt heat insulation, is used as the main layer. The mineral material is environmentally friendly and heat resistant. In the manufacture of it, it is impregnated with flame retardants, therefore, it attenuates during fires. The treatment of the fibers with boric acid prevents the onset of insects and small rodents. The positive aspects of ecowool use include:

- the minimum thermal conductivity is from 0.035 to 0.041 W / m × ° K;

- lack of evaporation of harmful substances during heating;

- high-quality closing of cracks and cracks during wet installation;

- small weight - cotton wool is laid on any thickness;

- long period of operation - from 40 to 50 years;

- lack of waste and the possibility of reuse.

The disadvantages of the use of the material include a high level of moisture absorption (about 20%), which is eliminated by arranging high-quality ventilation.

Foam boards

You can insulate the ceiling in the bath with polystyrene plates. The polymer material is different:

- low thermal conductivity (0.037-0.040 W / m × ° K);

- universality - heat-insulating panels cover the wall, ceiling and even the floor surface;

- ease of self-installation;

- preservation of thermal insulation properties for 30-40 years;

- resistance to fires - has only foam with flame retardant impregnation;

- low level of moisture absorption.

Among the minuses of heat-insulating plates - exposure to ultraviolet radiation, the emission of a harmful odor during combustion.

At elevated temperatures, the foam becomes poisonous.

Slag heaters

Fuel slag is a good material for creating thermal insulation of a floor or ceiling. When using it, carefully remove impurities - ash and coal. In the presence of impurities, the quality of insulation and sound insulation will decrease.

This option of warming is characterized by a number of positive aspects:

- high degree of thermal insulation due to loose structure;

- environmental friendliness - when burning toxins do not emit toxins;

- bactericidal qualities and lack of decay;

- resistance to fluctuations in temperature and humidity;

- lack of shrinkage and deformation.

When laying fuel slag there are difficulties with the roughness of the seam, which are easily masked by the finish.

Industrial waste must not be used on the premises.

Sawdust is a folk way to keep heat

Grandfather's method, in which lumber, cements or clay are used to prepare the mixture. Components are selected in a ratio of 10: 1: 1: 1,5. They will need to be thoroughly mixed in a dry state, then add water and knead a dense solution. The quality of the thermal insulation coating will depend on the thickness of the layer. After readiness, a foil insulation is laid on the coating.

Sawdust thermal insulation has several advantages:

- affordable cost of raw materials;

- ecological cleanliness - sawdust and wood shavings are natural materials;

- temperature and fire resistance of the finished heat insulation;

- good moisture resistance and vapor tightness;

- saving on arranging a vapor barrier;

- soundproofing quality.

The disadvantages of using sawdust are the complexity of the preparatory work, the significant weight of the material in the finished form.

Cracks on the dried mixture are sealed with the same composition.

Use of Penoizol

From the inside in the bathhouse it is allowed to apply penoizol. The material is made in the form of foamed plastic before insulation. Using equipment specifically, you can fill the voids in the wall, roof, flooring. Thermal insulation coating is different:

- lack of costs for the organization of bilateral insulation;

- fire resistance

- long operational period;

- resistant to rot and mold;

- simplicity of laying.

The disadvantages of the technology include the high cost of equipment and compliance with a clear application algorithm.

Penoizol can not be used in a timber bath or in the presence of concrete floors.

Other types of materials

It is possible to insulate the cold ceiling on your own in the bath using other materials:

- Expanded clay granules with a light and porous structure. Loose raw materials are made on the basis of clay; they are environmentally friendly and have a good heat-insulating effect. Expanded clay is resistant to ignition and exposure to a humid environment.

- Penotherm. The foam structure material was developed for work in saunas and baths. It holds heat well, has the ability to radiation, so the steam room heats up 2-3 times faster.

- Penofol. It is made on the basis of polyethylene foam and foil applied by spraying or laminating technologies. It is delivered in rolls or sheets. The metal layer reflects heat fluxes and also provides protection against extraneous sounds and vibrations.

- Seaweed. In the coastal zone, kamka is used, which is not exposed to moisture. It can be weighed in bales, in the form of mesh mats and dense plates. It features minimal heat storage.

- Growing aerated concrete. Designed only for concrete buildings. It is made on the basis of cement and pore-forming additives. Thermal insulation materials for secondary application have a density of 400 to 600 kg / m3, structural materials with heat-insulating properties - from 600 to 900 kg / m3.

Foil insulation in the event of a break will not retain heat.

Ways to insulate the ceiling surface

The thermal insulation layer is organized on the roof side or indoors.

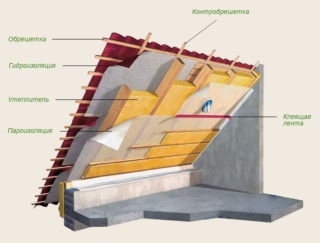

Roof side

The side to which the attic faces is insulated with foamed polymers, mineral wool, covered with ceramisite or sawdust. Thermal insulation is laid on reinforced concrete floors or between lags.Consider the features of the work outside can be an example of basalt wool.

- Arrangement of a waterproofing layer. The film is attached with an overlap of 10-15 cm using a stapler, and the joints are worked out with tape.

- Creating a sheet flooring from plywood or boards, which in the future will be the floor of the attic.

- Laying mineral wool between the beams so that the second layer covers the joints of the first.

- Installation of vapor barrier membranes with a “breathing” layer downwards, followed by fixing onto the beams.

- Installation of rails for insulation and filing of the ceiling.

Before laying bulk insulation on the beams, a draft ceiling is hemmed.

Insulation from the inside

Internal insulation for the ceiling in a bathhouse or sauna with a cold roof is suitable if a second floor is planned above the building. The correct algorithm of actions implies:

- Calculation of the coverage area, taking into account climatic conditions and room parameters.

- Preparation of building materials, tools.

- Installation of beams - the ceiling is placed on the strapping.

- Laying a vapor barrier and sealing joints. The vapor barrier is fixed with a ventilation gap of 2-3 cm.

- Installation of insulation layer.

- Organization of membrane waterproofing.

- Finishing the structure with lining or tongue and groove board.

No cement is used for flooring.

Preparatory work

Warming is organized according to the principle of puff cake, because the material must be protected from moisture and further dampness. To do this, you need to make a vapor and waterproof layer.

Arrangement of vapor barrier

For a bath without an attic, vapor barrier from aluminum foil, cardboard with drying oil or waxed paper is suitable. Attic buildings are additionally treated with clay laid in a 2-cm layer. Other materials may be used:

- 0.4 mm thick plastic film. It is laid with a ventilation gap through which condensate is discharged.

- Vapor barrier film with a vapor retention pile.

- A membrane that removes moisture from mineral wool. They also prevent condensate from entering the insulation and heat loss from natural ventilation.

In the presence of foam or penoizol on the roof, the vapor barrier does not fit.

Organization of waterproofing

If waterproofing was not carried out at the construction stage, several technologies can be used:

- Smear. One-component or two-component materials based on polymers or bitumen are superimposed on 2-4 mm.

- Okay. Fiberglass or bitumen-based roll materials are applied only on top of the concrete structure.

- Painting. Waterproofing coating is in the form of mastics, pastes or emulsions. It is applied with a brush, carefully smearing the corners. Enough 2-4 layers with a thickness of 2 to 6 mm.

- Sprayed. Liquid rubber is applied to external surfaces using special equipment.

On the ceiling of the bath, you can put polyurethane foam waterproofing, which will perform the functions of insulation.

Step-by-step instructions for thermal insulation

When insulating the ceiling of a bathhouse or steam room, depending on the type of room, the algorithm of work may differ.

Warming of the bathhouse

Walkthrough:

- Mounting on the bottom of the beam beams in the form of a box so that there are gaps between the elements of 5 cm. There should be a distance of at least 25 cm from the chimney to the panels.

- Impregnation of assembled shields with antiseptic compounds.

- Laying a vapor barrier and fixing it with brackets.

- Installation of shields, starting with the latter, so that their planes below converge with the beams.

- Installation of insulating material in boxes and joints of beams with shields.

- Organization of the upper flooring across the beams of boards or fiberboard.

- Processing the finished structure with fireproofing.

Elements of wood next to the chimney are covered with asbestos sheets.

Heat insulation of the ceiling in the steam room

The steam room should not let warm air out so that steam remains in the room. For this reason, insulation works include:

- The choice of moisture resistant material. Suitable boards soaked in two layers of drying oil.

- Installation of lumber on beams.

- Fixing boards over beams with a moisture gap of 3 cm.

- Laying insulation - reinforced foil, film or roofing felt.

- Filling the construction with slag or sand on a layer of 20 cm.

As a vapor barrier, glassine is used, and only then sand is poured.

Possible difficulties when performing work

Inexperienced builders most often make the following mistakes:

- Do not take into account the shrinkage of the log house, in which a 2.5 cm ventilation gap is formed on the ceiling. To eliminate it, the casing is completely removed.

- Install a heater under the floors in the steam room and sink. If you heat these rooms, boards can rot.

- Do not select insulation materials under the main. For wooden cladding, aluminum foil is suitable. In the presence of a dry steam room it is better to use expanded clay.

- Mount the hollow partitions of the ceiling. Mineral wool without vapor barrier will lead to the formation of fungus and mold.

- Use mineral wool or basalt slabs in highly heated rooms. When heated to 66 degrees in an unventilated room, materials emit harmful formaldehyde.

Polymer insulation must not be installed without a vapor barrier.

Depending on the type of room - washing or steam room in the bathhouse, insulation material is selected. Under conditions of high-quality installation, following the recommendations of experts, the building retains heat, creates comfortable conditions for relaxation and water procedures.