Living in a solid wood structure is comfortable, prestigious, and even healthy. But there are no ideal objects and houses from timber have their disadvantages characteristic of them. One of the disadvantages is the cooling of the floors of the first floor under the influence of air coming from cold soil. Walking on icy surfaces negates all the advantages of a building made of environmentally friendly material. Properly conducted insulation of the floor in a wooden house will permanently get rid of this problem. To do this, you need to choose the right materials and, in accordance with the technology, fix them on a carrier plate.

How to choose a heater

Concrete and screw piles suffer the most from cold earth. Their bases are not protected from environmental influences and can quickly become worthless. A wide range of heaters is on sale, which vary in price, appearance, application methods and operating conditions. Each material has its own advantages and disadvantages, which must be taken into account when planning work. In order not to make a mistake when making a decision, you should briefly familiarize yourself with the features of the most common heat insulators used in modern construction.

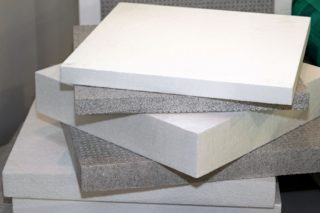

Penoplex

Penoplex is produced by passing the foamed polymer through an extruder. The result is slabs with an impressive list of positive characteristics. They are determined by the structure of the material, the structure of which represents many small closed cells. Blocks are available in the format 100 × 100 cm, with a thickness of 20, 50 and 100 mm.

The advantages of foam:

- low thermal conductivity;

- flexibility and resilience;

- wide temperature range of application;

- ease;

- ease of installation;

- water resistant.

Among the disadvantages of foam are instability to ultraviolet light and the emission of toxic smoke when exposed to high temperature. In addition, the polymer conducts sound well. This factor must be considered if the building is located in a noisy place.

Mineral wool

Mineral wool is a thermal insulation that has been tested for decades and has proven itself in a wide variety of conditions. Represents fibers oriented in space and densely interwoven among themselves. Available in mats and rolls depending on the thickness and raw materials used in the manufacture.

The following varieties of mineral wool are on sale:

- stone;

- slag;

- glass.

The most popular products among builders are basalt mats manufactured by Knauf.

The material is used to warm logs, supports, basements, floors and has the following advantages:

- light weight;

- incombustibility;

- good sound insulation;

- low thermal conductivity.

In addition to the high price, mineral wool has such a disadvantage as hygroscopicity. When saturated, a decrease in its performance occurs. In addition, during the installation process, many small fibers are separated from the material. Laying must be carried out in protective equipment and special clothing.

Styrofoam

Polyfoam is often used when warming a wooden floor, since along with an affordable cost it has a number of other positive properties:

- low thermal conductivity;

- water tightness;

- ease of processing;

- light weight;

- durability;

- resistance to temperature extremes.

The disadvantages of the material is that it decomposes under the influence of ultraviolet radiation, crumbles and breaks even with small loads.

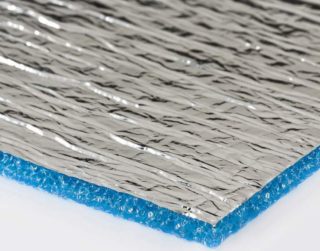

Foil materials

The decision to foil insulation was made based on the study of space technology. A thin layer of aluminum reflects heat back into the room, preventing the penetration of cold from the outside. Due to this property, the thickness of the porous component decreases, which has a positive effect on construction - useful volume is saved, thin material can be wrapped around structures of almost any complexity.

Penofol has the following advantages:

- ecological cleanliness;

- universality in application;

- good heat retention;

- excellent soundproofing.

The disadvantage of penofol is its limited service life. From contact with moisture, aluminum foil is destroyed within 5-10 years, after which water penetrates the porous structure and the material must be replaced.

Other heaters

Private building can be insulated in other ways, using raw materials of factory and own production.

To do this, you can use:

- Polyurethane foam. This is a binary substance that is applied under pressure using a spray gun. After solidification, a dense porous mass is formed, filling all voids. PPU has excellent thermal insulation and needs only protection against ultraviolet radiation.

- Expanded clay. Vulcanized porous clay balls are poured into the space between the rough and finish floors. The material has excellent insulating characteristics, is environmentally friendly, has an affordable cost. The disadvantage is that with time it becomes denser due to gravity and loses its working qualities. The material must be periodically changed, for which it is necessary to open the coating.

- Sawdust. Natural raw materials are inexpensive and well protect housing from the cold. Sawdust is used together with clay, making a thick solution. They are pre-treated with antiseptics and hydrophobic drugs. After hardening, clay can be used as the basis for laying the topcoat.

To choose the right heat insulator, you need to carefully consider all available aspects, focusing on the longevity of the filler.

Preparatory work

Before starting insulation, a number of measures must be taken to prepare the supporting structures and surfaces for long-term insulation. This is necessary to prevent the development of corrosion and decay of materials that are inaccessible to inspection.

Sequencing:

- Remove old coating. It must be disassembled carefully so as not to damage the supporting structures.

- Inspect wood, mark mold-damaged areas. Remove rot, reinforce these areas if necessary.

- To treat the structure with a flame retardant, antiseptic and hydrophobic agent.

- If access to the supports or the foundation is subsequently closed, equip them with waterproofing and cover with insulation.

After the preparatory work, you need to choose a method of floor insulation in a wooden house, make calculations and purchase the necessary materials. They must be purchased with a margin of 10-15%, taking into account errors and losses during transportation.

Warming options

Before starting work, you need to decide which side to lay the insulation materials on. Warming from the bottom gives these advantages:

- maintaining the height of the room;

- the point of contact with cold air moves away from the supporting structures;

- there are no restrictions on the thickness of the created layer;

- the ceiling is protected from moisture, insects, microorganisms and due to this it will last a long time.

The disadvantage of this approach is that it is convenient to apply at the stage of building construction. To insulate a wooden floor during operation, it will be necessary to dismantle it, which is fraught with breakage and spoilage of the previously laid coating.

Finishing on top can be done at any time, even several years after the completion of construction. But this is the only plus of such technology. Cons are the following:

- you need to choose the finish with a hard surface;

- the overlap is in contact with the external environment and quickly becomes worthless;

- due to raising the floor level, the height of the room decreases.

Experts recommend applying insulation from below, as this is the optimal solution in all aspects.

Step-by-step instruction

Before starting repairs, you need to draw up a competent diagram. She will help to complete the work accurately, in compliance with the desired sequence.

Step-by-step instructions for conducting insulation:

- Laying on the logs of draft boards. They will be the basis and support for all subsequent layers. Slots are sealed with mounting foam or tape.

- Laying a vapor-permeable membrane. It is necessary to remove moisture generated in the room. The fabric is fastened with a manual stapler with 6 mm staples.

- Create a wireframe. The height of its walls should correspond to the thickness of the insulation. If a solution or bulk material is used, its layer should be at least 20 cm.

- Installation of thermal insulation. This procedure is carried out in accordance with the technology that applies to each type of material. Pay attention to the absence of gaps.

- Installation of waterproofing. For this, webs that conduct moisture in one direction are best suited. The stripes overlap each other with an overlap of 15-20 cm. The joints are fixed with tape.

- Laying the finish floor. The choice is determined by the type of finish. For linoleum, parquet and carpet it is better to take inexpensive sheets of waterproof plywood with a thickness of 16-25 mm. A massive board can be laid directly on the frame. In this case, take rails with selected edges so that there are no through slots in the surface.

Since the main advantage of a wooden structure is its ventilation qualities, the finish must be selected similarly.

Common Errors and Problems

When carrying out warming of buildings made of wood, novice masters make mistakes at various stages of construction.

- Unpacking the insulation long before installation. As a result, the material is saturated with moisture and loses its characteristics.

- Incorrect installation of thermal insulation. With strong compression, the thermal conductivity increases, and the slots are cold bridges.

- Ignoring the preparatory phase. If mold is not removed from the wood, it will continue to break down until it cracks or breaks.

- Lack of treatment of boards and logs with an antiseptic. Under the influence of dampness, a fungus starts in them, which soon leads to unscheduled repairs.

- Insufficient insulation layer. Saving or incorrect calculation leads to the fact that in severe frost, insulated floors still freeze.

- Using vapor barrier film. The result is condensation under the coating and decay of the filler.

- Violation of the sequence of laying materials. The result is the penetration of damp inside the finished "pie".

To avoid such errors, you must act in strict accordance with the plan, strictly following the instructions specified by the manufacturers of building materials.