Warming the loggia with penoplex is an effective solution to the issue of preserving heat in this room in the winter and protecting it from high temperature in the summer heat. The material has a number of unique operational characteristics, which is why it is in demand in private and industrial construction. Do-it-yourself warming of the balcony with penoplex is a simple and safe event, for which professional skills and special tools are not needed. In addition, you can perform the work alone, which further reduces the repair budget.

Can penoplex be used for loggia?

GOST, SNiP and SanPin do not contain any restrictions regarding the use of foam as insulation for residential, office and administrative buildings.

The use of this material is dictated by such factors:

- Previously, the external premises were used as a warehouse and a place for drying clothes, but now this attitude has changed radically. If you insulate the balcony with your own foam, you can use it as an office, workshop, gym or greenhouse.

- High-quality thermal insulation creates a protective barrier with an adjacent room. Due to this, it maintains a comfortable microclimate, less heating bills.

- Prevention of dampness and development of mold on supporting structures. Warming the balcony with foam plastic extends the life of the building and minimizes the likelihood of costly overhaul.

Since it is forbidden by law to take out water and electric radiators in the loggia, the best solution is to use heat-insulating boards in combination with high-quality waterproofing materials. This is not a violation, and in some regions it is encouraged financially, as part of energy saving programs.

Choice of type and thickness of material

Work begins with the design, calculation and procurement of materials. Penoplex is available in the form of plates of the format 100 × 100 cm and 100 × 200 cm. The edges of the parts are made in the form of a step to ensure a reliable and tight connection.

Depending on the installation site, plates of this thickness are used:

- for walls - 20 mm;

- for cold ceilings and balcony grilles - 100 mm;

- for floor and warm ceiling - 50 mm.

When planning, it should be borne in mind that in order to carry out high-quality insulation, it is necessary to purchase a large number of fixing, connecting and finishing materials.

To work, you will need:

- waterproof drywall;

- glossy PVC panels;

- laminate;

- foamed penofol;

- glue;

- facade plaster;

- membrane film;

- wooden beam;

- deep penetration impregnation;

- antiseptic;

- dish-shaped dowels;

- polyurethane foam.

The list can be expanded depending on the design of the finished premises, its size and configuration.

To conduct insulation, you need to prepare the following tools:

- level;

- hammer drill;

- hammer;

- stationery knife with spare interchangeable blades;

- aluminum tape;

- hacksaw or electric jigsaw;

- iron ruler;

- steel spatula.

Since part of the work will be carried out at height, it is advisable to have a stepladder. To protect the skin, organs of vision and breathing, it is necessary to use a helmet, safety glasses, gloves and a gauze bandage.

Insulate externally or internally

You can insulate balconies from the inside or outside. Each technology has its own characteristics, pros and cons. To make the right decision, you need to consider all the nuances in detail.

External insulation affects the parapet and side walls of the loggias. Advantages of this approach:

- Contact with the environment occurs on the surface of the finish. The supporting structures are protected from negative environmental factors.

- The useful space is not reduced. This is true for small rooms, especially if custom furniture is installed in them.

- There is no condensation and dampness, the risk of mold, fungus and deterioration of the finishing material completely disappears.

Cons are also available:

- The difficulty of carrying out. Without scaffolding, insulation can only be done on the ground floor.

- Possible limitations. Often there are bans on making changes to the facades of houses, especially on the central streets of settlements.

Benefits internal work:

- Convenience and safety.

- There is no need to coordinate their actions.

- The ability to conduct on their own.

Cons of this option:

- Reduction of the internal volume of the room.

- Negative environmental impact on supporting structures.

A decision should be made after evaluating all factors, taking into account the budget and prospects.

Preference should be given to internal insulation, since loggias are much easier to repair and replace after wear of the insulation.

Step-by-step instruction

Finishing the balcony is better in the warm season, after a steady weather. Rain, snow, wind and temperature changes are not the best helpers in the work. Even in a glazed room, it is necessary to open the windows for ventilation. Warming is carried out in stages, in compliance with all the nuances of the technology. You can only screed in the loggias, which are based on the side walls. It is forbidden to weight the balconies, as this is fraught with their destruction.

Balcony preparation

First you need to study the condition of the structure. If it is very dilapidated, it is necessary to carry out restoration measures. For this, side iron beams or vertical supports for the first floor can be installed. Old wooden windows should be replaced with new ones with energy-saving double-glazed windows.

After this, the following activities should be performed:

- Remove all furniture, flowers and other objects from the balcony that could interfere with the repair.

- Remove the old finish from the surfaces. Seal through holes and gaps with sealant.

- Measure the level of curvature of the walls, floor and ceiling with a level. If necessary, smooth them with plaster.

- If you plan to electrify the loggia, make strobes and holes for mounting boxes. Lay communications in flexible plastic tubes in them. Coat the channels and openings in the sockets.

- To treat surfaces with a deep penetration primer, wait for it to dry completely.

- Apply a layer of waterproofing. To do this, you can choose a film or coating materials.

Further work can be done after all adhesives have dried and become permanent.

Penoplex insulation

Installation is carried out in the direction from the bottom up. So each subsequent surface will have a support for mounting.

Thermal insulation of the floor in the loggia with foam:

- On the basis of the frame is made of wooden beams. Pre wood is treated with an antiseptic. Crossbars are stacked with an interval of 100 cm, which corresponds to the width of the insulation.

- Plates fit into the openings. The edges are neatly cut with a clerical knife and glued together. Side openings are filled with foam.

- A membrane film is laid on top and fixed with brackets.

Further actions depend on the type of finish chosen. If it is planned to lay parquet, linoleum or laminate, the frame must be sheathed with thick plates, which will serve as an even and solid foundation. Massive and engineering boards can be laid directly on the frame.

The method of wall cladding is determined by the type of finish. If these are panels or plates, it is necessary to make the crate into which the insulation is inserted. It simply sticks to the surface, then closes with a membrane. The casing is attached to the frame with brackets or screws. If it is planned to use facade plaster, in addition to glue, penoplex is fixed on the base with plate-shaped dowels of 5 pieces per square (in the center and corners). Then the building grid is glued to the insulation and only then plaster and paint are applied.

Insulation of the ceiling is carried out by analogy with floors and walls:

- Production of a lathing from a bar or a steel profile.

- Laying in the frame of plates with glue pre-applied to them.

- Drilling through holes in the ceiling plate, driving plate-shaped spatulas into them.

- Filling the gaps with mounting foam, cutting off excess after hardening.

- Covering the lathing with a membrane film.

If necessary, a grid is glued to the slabs if further plastering is planned. But such decisions are rarely made, since their implementation is time-consuming and impractical.

Finish finish

The choice of material for the finish is based on the tastes of the owners and the characteristics of the room. If it is open, use waterproof coatings that are resistant to temperature extremes.

The following options for finishing surfaces for various purposes:

- floor - solid and engineering board, ceramic and stone tiles, linoleum, carpet, laminate and parquet;

- walls - plaster, tile, non-woven and liquid wallpapers, MDF, wooden battens;

- ceiling - drywall, PVC panels, metal battens, tiled systems, stretch canvas.

It is recommended to use durable and expensive materials with a long service life. The right choice will allow you to forget about the repair for a long time.

Advantages and disadvantages

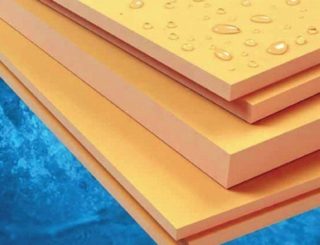

Penoplex is a modern insulation material with closed internal cavities. Its operational characteristics are superior to foam, tile and roll counterparts.

Products have the following advantages:

- Low thermal conductivity. Due to this, the supporting structures are reliably protected from the damaging effects of the environment.

- Wide temperature range of operating conditions. The material can be used in almost any region of the country except the Far North, where the temperature drops below –50 ºС.

- Water resistant. Penoplex does not absorb moisture, mold and fungus do not form on it, insects and rodents avoid contact with a heater.

- Density. Plates have a spongy structure, making them easy to cut, they do not crumble during transportation and installation.

- Safety. The material does not emit substances harmful to human health and does not burn, melting at high temperature.

- Low specific gravity. It is easy to work with panels; they do not exert serious load on bearing surfaces even when laying in several layers.

- Elasticity. Plates bend well; they can be used to finish curved surfaces, which are often found in both old and modern buildings.

- Long term of operation.Manufacturers guarantee a foam service life of at least 50 years, subject to the technology of transportation, storage and installation.

This unique heater has its drawbacks. It is destroyed by ultraviolet radiation. Therefore, appropriate cladding is needed. During installation, do not use substances containing toluene, upon contact with which the insulation melts. The downside is poor sound insulation.

Penopleks poorly protects the loggia from street noise. It should be combined with other materials, but this leads to an increase in coating thickness.