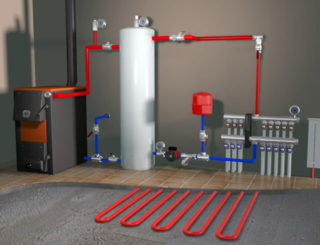

The combined heating scheme with underfloor heating and radiators in a private house is used for convenience and efficiency. It is easier to regulate the heating of rooms, in case of breakage there is always a backup option. The correct choice of a heating unit, circuit and devices leads to savings in energy and money. System operation is coordinated manually or automatically.

Features and benefits of a combined system

The project is used in buildings for various purposes and any number of storeys with the correct selection of components and flooring. The warm floor of the first floor gives upward thermal currents, warming the ceiling, which on the second floor serves as flooring.

The owner chooses the optimal combination of equipment independently, taking into account the following factors:

- home needs, owner preferences;

- fuel availability and price;

- the possibility of implementing the scheme;

- consumption of materials.

The radiator circuit reacts to a decrease in room temperature due to bad weather, creates thermal thresholds under the windows in frosts. Batteries on cold days increase the heating of the room without raising the temperature of the warm floor to an uncomfortable state.

The main one is the heating laid in the foundation. Warm floors are used in the off-season, when the house cools down and humidity appears.

The radiator system is put into operation manually or automatically during the period of deteriorating weather for efficient heating of the house.

Choosing a heating boiler

The scheme of connecting underfloor heating and radiators to the boiler depends on the selection of a heat source. The separation of the units is determined by the type of fuel that they consume.

Boilers are:

- solid fuel;

- gas;

- liquid fuel;

- electric.

Solid fuel equipment has different capacities and works on peat briquettes, coal, coke, firewood and wood waste. The boiler efficiency is in the range of 50–70%, some models reach 80%. Units consume about 46–47 kg of fuel per square foot per year, excluding water heating, and are installed in houses from 30 to 2500 m2. A powerful chimney and ventilation are required, installation permission is not issued.

Gas units operate from balloon or main fuel. Power ranges from 10 to 15 thousand kW, efficiency reaches 92–94%. Gas in the volume of 0.113 m3 is required for the production of 1 kW of thermal energy. Heats houses up to 400 - 500 m2, requires forced smoke exhaust and ventilation. To run, permission is issued by the relevant authorities.

Oil-fired units use fuel oil, diesel fuel, oil processing, and the efficiency is in the range of 86–92%. The consumption of liters per hour is calculated by multiplying the burner power by a factor of 0.1. The equipment smokes during operation and is installed in a non-adjacent room with living rooms. It does not require permits for installation.

Electric boilers are also used in the heating system of a private house with underfloor heating and radiators and are powered by electricity. The power of equipment for housing ranges from 4 to 30 kW, the efficiency indicator is 87–98%. There is no soot, silent operation, the boiler heats an area of up to 300 m2. It does not require ventilation and chimney equipment, it is connected to a three- or single-phase network without issuing an installation permit.

Choosing an electric or water floor

The electrical system includes a heating link in the form of mats, film or cable, temperature sensors and a glow regulator (electronic or manual). The design does not significantly raise the floor and does not affect the height of the room. The system heats the surface evenly. The optimal mode is established by combining sensors and thermostat, heating stops when the specified parameters are reached.

Electric floors are mounted without additional labor:

- the wire is laid out on a plane;

- a concrete screed is made;

- mounted flooring.

A water heated floor with a pipe system does not allow uniform heating of the room area, but its installation and operation is cheaper. Installing pipes in the screed requires more time and labor. The kit includes a circulation pump, manifold and pipes. The water system plus screed raises the surface by 7 - 9 cm. The automatic or mechanical adjustment mode is selected.

The choice of the type of floor heating depends on the heating system and the possibilities of the owner. The fuel consumption for surface water heating is taken into account and compared with the costs in order to heat with electricity.

Radiator selection

An air heat exchanger dissipates heat into the surrounding space through convection and radiation. Radiators vary depending on the material from which they are made:

- steel;

- cast iron;

- bimetallic;

- aluminum.

Steel panel radiators are notable for their average price, they have a universal connection, they last 25-30 years. Elements are available in different sizes in height and length. Steel batteries withstand a pressure of up to 8 atm, with a test indicator of 25 atm, require a preliminary calculation of power. Elements are destroyed due to corrosion in places that have been damaged.

The old-fashioned cast-iron batteries are large in size and weight, there are modern models of small sizes, developed jointly by designers and designers. Service life - up to 50 years, withstand pressure of 6-10 atm, with a test indicator of 15 atm. Elements resist corrosion, are prone to clogging with calcium deposits.

A steel distribution manifold is installed inside the bimetallic radiators, which increases the working head up to 25 atm. The batteries are combined with different pipes, they are light in weight. The cost of the elements is high, the use of antifreeze is not recommended, because leaks occur.

Aluminum batteries give off heat well, they are attractive in appearance and light in weight. You can dial a different number of sections, install in gravity heating circuits, but only closed systems. Working pressure in the range of 7-12 atm, with a test indicator of 25 atm. Interaction with copper elements causes the appearance of currents that contribute to corrosion.

What pipes are suitable for a combined heating system

Products are selected taking into account quality, cost, reliability, service life and ease of installation.

Copper pipes heat up quickly and effectively give off heat, the circuits of such elements are distinguished by excellent technical characteristics and corrosion resistance, they have been in operation for 50–80 years. Products are expensive, installation is carried out only by specialists because of the complexity of working with copper.

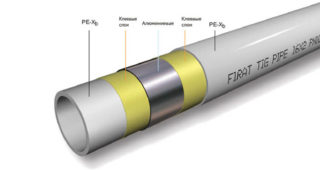

Polypropylene pipes are available with aluminum and fiberglass reinforcement. In the first form, the metal layer keeps the polymer from undue expansion. Requires mastery in welding, becausedelamination often occurs. Fiberglass pipes represent durable and quality products due to their solidity.

Plastic pipes differ in acceptable performance and are used for the radiator circuit and underfloor heating. Inside is a layer of polypropylene with smooth walls, which does not collapse and does not oxidize. Polyethylene is connected to the aluminum pipe with an adhesive layer. Products are mounted easily and do not require special skills, pipes bend, connections are made by press or threaded fittings.

Cross-linked polyethylene collectors are used for underfloor heating. Tightness is achieved using press fittings that are easy to install. The material serves for a long time, has little wear and conducts heat well.

Installation Organization

The complexity is the implementation of wiring into 2 circuits with different energy temperatures. A serial connection scheme is used for connecting the underfloor heating and batteries from one boiler and a water gun. The first wiring saves resources, and the second allows the unit to work in optimal mode.

The energy carrier is supplied to the underfloor heating pipes with a low temperature compared to the radiator circuit. Heating is regulated automatically as they cool in each branch. The line is turned off by stopping the pump. Pipes for underfloor heating choose a section of up to 20 mm to reduce the inertia of the system.

In private homes

To the scheme of a combined heating system with radiators and underfloor heating, there are basic queries that need attention. The equipment is freely available for inspection and repair. The risk of fire and explosion is taken into account.

Installation Rules:

- The water temperature should be 20 ° C higher than the ignition limit of the substance, boiling of the energy source is prevented. The boiling rate depends on the pressure in the system. For example, at a pressure of 2 atm, water boils at + 120 ° C.

- The heating of the surface of the exposed parts of radiators and pipes must not exceed permissible norms.

- Equipment and instruments are isolated to protect against burns, energy losses and freezing in unheated buildings.

- Hot parts close if they can cause ignition of gas, dust in the room.

The design, calculation and selection of the heating system remains important.

In apartments

Additionally, thermostats are used by the number of batteries to coordinate the temperature. The automation of the unit maintains the temperature of the energy carrier. Cranes are installed on the branch lines to selectively turn off the batteries or underfloor heating circuits.

Mayevsky cranes are installed according to the number of devices, a safety group is mounted, including an expander, a pressure gauge, a safety valve and an air vent. Radiators of the main circuit are cut in series in a diagonal pattern or from bottom to bottom. The horizontal level is maintained to get rid of water noise.