A warm floor in a wooden house is a combination of control devices and heating elements located between the bottom floor slab and the finish. Depending on the type of devices and materials used in the construction, these structures can be part of a common heating system or perform this function independently. With a competent approach to design and correctly completed installation, underfloor heaters effectively cope with maintaining a comfortable microclimate in all rooms of the building.

Is it possible to make a warm floor in a wooden house

The owner of a private building is free to equip any type of main and auxiliary heating. Restrictions apply to water circuits in multi-storey buildings, where several families live and have common communications. The reasons for the ban are that the pipes filled with water, together with the screed filled in, are heavy, creating an unacceptable load on the walls and floor slabs. In addition, the possibility of leaks due to rupture of the pipe walls or wear of the cushioning material at the joints is not excluded. Even in a one-story building, this is a danger. It lies in the fact that water can undermine the foundation and damage communications located on the basement level. Another factor is the heat loss that occurs in the riser due to the circuit built into one of the apartments. Having passed through it, the water cools down and gets to the neighbors from below in a cooled state, which adversely affects the microclimate in their housing.

If the housing is private, its owners themselves are responsible for their own safety. There are no restrictions on the arrangement of additional heating, since the interests of the state, the management company and neighbors are not affected.

But this does not mean that you can approach this event superficially. Own funds should be invested thoughtfully and as efficiently as possible. Otherwise, the bills will grow, and the level of comfort will not change.

Which type to choose

When building a house made of solid wood, lightweight reinforced concrete slabs or timber can be used as floors between floors. Both materials have their pros and cons. Hollow slabs weigh more, but are stronger and better retain their shape. The beam is light, it can be laid manually, but it tends to bend under its own weight and the impact that people and furniture have. In most cases, the finish of the floor slab is wood in the form of boards, parquet, plywood or laminate.

When choosing the type of floor heater, the following features of wood should be considered:

- Low thermal conductivity. If heat sources are placed under the boards, it will be almost completely absorbed by them. An exception may be varieties of wood, characterized by high density: oak, larch, cedar. They conduct heat well, but are so expensive that not everyone can afford it.

- Susceptibility to deformation. With constant heating, moisture leaves the material, it loses volume and becomes covered with cracks. If the heat supply is interrupted, the wood absorbs moisture, expands and bends.

One of the options for a universal finish coating can be an engineering board or wood-polymer composite. These materials have high thermal conductivity, lightness and water resistance.At the same time, their cost is quite affordable even for budget construction.

There are two identical in purpose, but different in principle of action type of warm floor - water and electric.

Water floor

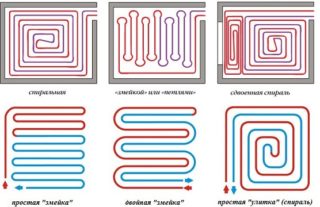

Designs are closed loops of a spiral or serpentine configuration. Water in the pipes moves under pressure, which creates a centrifugal pump.

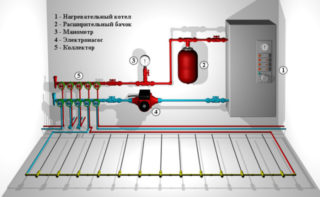

Water heated floor in a wooden house has the following device:

- Pipes along which fluid moves. Depending on how the structure is used, ordinary water or antifreeze is used. The circuit is made of metal fragments, polypropylene sections or special flexible plastic pipes.

- Collector. The product is used to connect and adjust the pressure in several circuits when a large area is being arranged.

- Boiler. It can be gas, electric or solid fuel. It is a source of energy that heats the coolant.

- Mixer. It is used to regulate the temperature of the liquid that is supplied to the pipes. To determine the desired value, a hand is applied to the nozzle, after which the crane is turned.

- Thermostat. It is used in automatic systems that operate without human intervention, including in remote access mode. Maintains fluid temperature in specified parameters.

- Fitting. Depending on the system design, shut-off and drain taps, relays and automatic stoppers are installed.

A feature of water systems is the need to fill the screed, which receives and distributes heat over the surface, while protecting the contours from mechanical damage. You can make a screed from any heat-conducting material - cement mortar, polymer or epoxy. The finishing requirements are similar requirements - it should conduct heat well. To achieve the desired effect, ceramic tiles should be laid on the base or decorative liquid mass should be poured.

Electric floors

Electrical systems do not have such risks that are inherent in water counterparts. The structures are lightweight, easy to install and require no maintenance. It should be borne in mind that there is always a risk of fire in the event of a critical increase in temperature or a short circuit on the line.

There are such varieties of electrical appliances for heating floors:

- Cable. Products are wires enclosed in flexible insulation that are uniformly heated along their entire length under the influence of current. Stacked in forms, on a metal mesh or between rotary beacons. They have a thickness of 6-15 mm, power 20-40 W / lm. After laying, they are poured with cement mortar.

- Mats Made in the form of thin wires fused into a flexible plastic mesh. They have the form of strips up to 200 cm long and with a power of 120-250 W / m². The thickness of 2-3 mm allows you not to make a screed, but immediately cover the mats with adhesive composition while laying the tiles on the floor.

- Film. Inside the flexible strips with a thickness of 0.5-0.8 mm are carbon-coated copper conductors that energize infrared radiation. A feature of the film is the absence of the need for screed, since the radiation passes through all materials. Strips can be glued to the base, and then covered with tiles, linoleum and all types of wood flooring. Product power varies between 100-200 W / m².

The choice of a floor heating system is made based on the characteristics of the room, the condition of the finish and the advisability of interfering with the flooring.

The device of a heated floor in a private house

Since the floor slab is in contact with the underfloor or directly with the ground, special attention is paid to its insulation and insulation.The objective of this event is to create a reliable barrier against cold and damp. In addition, mold-resistant materials that provide ventilation and steam extraction should be selected.

Since the floor slab is in contact with the underfloor or directly with the ground, special attention is paid to its insulation and insulation.The objective of this event is to create a reliable barrier against cold and damp. In addition, mold-resistant materials that provide ventilation and steam extraction should be selected.

In a private house, the insulated floor consists of the following layers (from bottom to top):

- Rough flooring. Stacked on blocks or columnar brick supports. Serves as the basis for subsequent designs. It is made from boards treated with antiseptic preparations against microorganisms and insects.

- Membrane insulation. Diffuse membranes and films are used that remove moisture from the premises in one direction. There are insulation for floors arranged above the basement and on the ground.

- Insulation. Synthetic and natural materials are used as filler - mineral wool, penoizol, ecowool, expanded clay, peat, felt, straw, wood shavings.

- Vapor barrier. Used membrane films and fabrics, fixed on the frame.

- Fine floor. Represents the basis which is made of plates, boards or boards. Depending on the quality of the materials, it is used as a topcoat or base for laying the finish.

If a concrete slab is laid on the base, waterproofing materials such as polystyrene and polyurethane foam can be used to warm it.

How to install

Installation of underfloor heating of all types begins with the drawing up of a scheme, calculations and the purchase of building materials. The next step is the arrangement of the base.

- Finish is removed. If you plan to use it again, dismantling must be carried out extremely carefully.

- The base is cleaned of debris, dust and protruding fragments. Narrow gaps widen and seal with sealing material.

- The carrier plate is treated with a primer of the appropriate purpose.

- Depending on the type of floor, waterproofing layers and insulation are laid.

After that, the laying of the heating elements begins. This is done in accordance with their configuration:

- The cable is laid in pre-prepared forms. In this case, it is necessary to observe the minimum bending radius in order to prevent its kink. After checking the fastening strength, the screed is poured.

- Mats are attached to glue or double-sided tape. They should be placed 20 cm from the walls, can be cut to the desired shape. An object with a low bottom should not be allowed over the elements, as this contributes to overheating of the wire.

- The film is glued to the plate with construction tape. To prevent damage to the trim elements, a special protective sheet is laid on top of the film.

- Water pipes are laid by a snake or a spiral. When choosing the shape of a snake, it is better to use shaped foam blocks with grooves.

After laying, a performance check is carried out. If everything is functioning properly, screed is filled and finished.

Advantages and disadvantages

In order not to make a mistake in choosing, you should consider the pros and cons of each type of warm floor.

Water devices:

- small starting and operating costs, inertness of heating and cooling;

- difficult to establish, there is a risk of a breakthrough of the highway;

- only covered with screed.

Cables:

- simplicity of installation and operation;

- loss in height, high electricity consumption.

Mats:

- simplicity of laying, insignificant thickness, profitability;

- high cost of items.

IR film:

- reasonable price, profitability and universality;

- fragility, easily tears and breaks.

When arranging a house, it is better not to dwell on one type of underfloor heating, but to select it individually for each room.