The definition of "ceramic heater" - sellers of heat engineering apply to different classes of devices, differing in principles of operation and design. Combines the devices used in the manufacture of fired clay. The breed is mixed with mineral fillers to give the desired properties. To choose the right electrical appliance in the house, you need to study the device, purpose and characteristics.

Varieties and arrangement of ceramic heaters

The main types of heaters are powered by two types of energy: electricity and gas (natural or liquefied).

Gas models

The design of the apparatus includes ceramic gas burners, gas supply pipes and automation devices. The combustion of fuel inside the device occurs without flame.

A ceramic burner emits thermal infrared waves into space when heated. There is heating of floors, walls and furniture in the room. Gradually from heated objects, the air temperature rises.

Gas units are simple in design, but require strict adherence to safety regulations. Regular routine inspections and maintenance are allowed to be performed only by certified organizations. Because of this, gas appliances are not widely used in residential buildings.

At the same time, the devices are perfectly suitable for heating the working area in open areas - it is not the air that is heated, but the human body. This contributes to a comfortable stay on the street.

Electrical devices

Electric ceramic heaters are safe when installed correctly in residential premises, so they are widely used.

Devices belong to devices of direct heating - the energy of electric current is converted directly into heat without the use of an intermediate coolant.

For the distribution of heat, infrared radiation, convection, or a combination of these phenomena is used.

Depending on the design, the heaters are divided into ceramic radiators, ceramic infrared heaters and fan heaters. Each device is best suited for individual tasks.

Convection devices

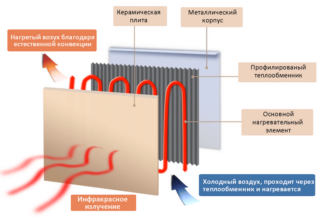

Structurally, heating ceramic panels consist of a nichrome spiral mounted in a protective panel made of a mixture of clay with various mineral additives.

The flowing current causes the coil to heat up, which transfers heat to the ceramic body.

The temperature of the outer surface at maximum power reaches 90 ° C, which causes a convection effect. Cold air, heating up, rises, chilled falls to the floor. Further, the process occurs continuously. This principle is fundamental in the operation of heating panels.

At the same time, a small part of the thermal energy is emitted into the space in the form of infrared waves.

Advantages and disadvantages of panels

Due to the design features, each household appliance has positive and negative qualities.

Advantages of ceramic panels:

- ease of installation and maintenance;

- long service time (up to 25 years);

- relatively low price;

- do not burn oxygen;

- heating adjustment;

- attractive design;

- silent operation;

- Efficiency for converting electrical energy into thermal energy up to 98%.

At the same time, ceramic radiators have disadvantages:

- dry air, but this property is inherent in all heating devices;

- large mass and stationary installation - the device is not easy to transfer to another room;

- Installation in damp rooms and outdoors may result in electric shocks.

Structurally produce wall and floor ceramic heaters.

Not all manufacturers have brackets for mounting on a vertical surface are included in the kit, it is necessary to purchase parts for a fee.

At the same time, thermal inertia is attributed to the advantages and disadvantages - massive panels warm up for a long time, but also cool for a long time after shutdown. The property makes it difficult to use panels to heat summer cottages visited for the weekend - a full warming up of the housing can take up to an hour.

Preferred Installation Locations

Heating panels are used as primary or secondary heating. The second option is suitable for heating rooms at night or on cold days.

If it is supposed to install the main heating on the basis of convectors, take into account that on average 100 watts of power will be required for heating 1 m2 of the area.

Most panel radiators are designed for power from 200 to 400 watts - this is enough for an area of 5 - 6 m2 with a ceiling height of 2.6 m.

An accurate heat engineering calculation is possible only by qualified specialists, taking into account climatic conditions in the place of residence, type of building materials, quality of insulation of floors, walls and roof, number of windows and glazing area.

Market leaders

Tepladar - The plant of the Russian manufacturer is located in Ulyanovsk. The main model with a power of 400 W is designed for heating rooms with an area of up to 6 m2 or a volume of up to 17 m3. The mass of the device is 10 kg. Dimensions: 68x35x3 cm.

The tepladar is mounted on a vertical or mounted on a horizontal surface.

When buying in online stores, you can buy goods at a stock. As gifts, they offer brackets for wall mounting, a temperature regulator, a reflective screen and sidewalls that enhance convection.

Nikaten - Krasnodar brand of heating equipment. The range of convectors includes appliances with power from 0.2 to 0.65 W / h. The front panel is painted in one tone or wood.

Depending on the power consumption, the height varies from 30 to 60 cm, the width is -60 - 120 cm. The maximum thickness is 4 cm.

Luxor - Italian manufacturer of luxury appliances. The power of the devices is fixed - 0.35 or 0.7 kW. To save energy, all models have built-in temperature controllers that respond to air temperature at the installation site. The range includes designer ceramic granite heaters, the color and texture of which can be selected for any interior.

Infrared emitters

The device incorporates the principle of operation, which consists in the emission of infrared waves. Reaching the surface of walls, floors, objects, their radiation heats.

Preferred Use

For use as the main heating infrared ceramic heaters are poorly suited. This is caused by a number of properties:

- heating takes place in a limited area where the emitter is directed;

- a long exit to a given temperature temperature of the air, as objects are heated first;

- burnout of colors of decoration materials under the influence of infrared waves.

Do not direct the ceramic infrared heater toward flammable objects or containers with flammable substances. The “ray” of heat leaves traces in paintings, photographs, wallpapers.

Structurally, the devices are ceramic tubes, inside of which a spiral is heated, heated by an electric current.

New devices are made in a different way. The spiral is "flooded" with ceramics. The shape may be flat or concave. Separate models are adapted for screwing into a cartridge instead of an electric lamp.

It is important to consider the power of the device if a switch is used to interrupt the circuit - the current consumption must not exceed the set limit.

Ceramic infrared heater has a number of positive properties:

- the radiation begins immediately after the current is supplied, and reaching the maximum mode takes several minutes, which is convenient when visiting an unheated cottage;

- suitable for heating workplaces in open areas;

- used for heating seedlings and chicks of poultry;

- power devices can reach 1000 watts.

In everyday conditions, ceiling IR devices made of glass ceramics have become widespread. They are installed in hallways, vestibules, baths, utility rooms, workshops and garages. Ceiling mounting saves space in small rooms. It is not possible to accidentally touch the device, burn yourself, or receive an electric shock if the wiring is damaged.

The devices are manufactured by Icoline, Timberk, Peony, Almak.

Ceramic fan heaters

Fan heaters consist of a heating element, a fan, a housing and controls.

New models of fan heaters have a ceramic heating element in their design, rather than an open spiral.

Positive qualities of devices:

- quick exit to heating mode;

- do not burn oxygen as open-spiral models;

- there is no burning smell from burnt dust;

- wide range of power adjustments;

- high performance fans.

There are two options for the location of the impeller - tangential and axial.

In the first case, fan heaters have an elongated body, which is best placed on a wall or ceiling.

Negative properties are associated with the noisy operation of axial fans. In addition, low-cost models are equipped with plain bearings, the bronze bushings of which wear out quickly. Additional vibrations appear, further enhancing the emitted noise.

Air flows draw dust into the enclosure - in the utility rooms, sheds, houses, frequent cleaning of the inside of the enclosure will be necessary. On this basis, devices with fans are turned on for a short time for quick heating.

Fan heaters are not used as the main element of the heating system, since they do not withstand continuous operation.

Popular manufacturers: Delta, Polaris.

Not all fan heaters are equipped with ceramic elements - some of the products work with open spirals. The complete set should be specified at purchase.

Optional memo

Correctly choose a ceramic heater will help the data collected in the table.

| Convection panel | IR heater | Fan heater | |

| Main heating | + | — | — |

| Auxiliary heating | + | + | + |

| Installation locations | Living rooms, outbuildings | Utility rooms | Utility rooms |

| Initial warm-up time | long | long | quickly |

| Inertia of the device | high | low | low |

| Outdoor heating | no | Yes | no |

| Power range, kW | 0,2 – 1,0 | 0,5 – 2,5 | 0,5 – 2,0 |

Ceramic heaters with the right choice allow you to equip the main or auxiliary heating of residential, utility rooms and farm buildings. A good result can be achieved by a correct assessment of operating conditions and tasks solved by electrical appliances.