Thermal insulation of pipes of the heating system is the most important task for high-quality heating of the house. Thanks to the additional insulating layer, the water and heating pipes will remain at a higher temperature for longer. To perform the insulation of an external heating system in a private house or apartment, you can independently using different methods.

The need for insulation of heating pipes

At first glance, it might seem that pipe insulation in apartment buildings that carry hot water is not required. But in practice this is not so. The heating circuit always has a high temperature, since the coolant circulates in it. But the outside temperature is always lower, which is why heat carriers cool faster. The insulation will keep heat for a long time. The use of insulation materials for pipes when laying a heating main underground or outdoors is especially important. The laying rules are regulated by GOST, SNiP and other standards.

Lack of insulation is economically unprofitable. If there is no insulation layer, the walls of the coolant pipe are in direct contact with the cold air in the street and cool quickly. This leads to a decrease in temperature throughout the heating system and heated rooms. The efficiency of such a system is minimal - a lot of fuel was spent on heating the water, and the room temperature is not high. Insulation allows you to increase efficiency, reducing heat loss.

Insulation requirements

The modern market offers a wide range of materials for insulation. All of them have their own characteristics, features, operating conditions. When choosing a heater for pipe insulation, you must rely on the following parameters:

- Thermal conductivity. The lower it is, the better the heat will be retained.

- Hygroscopicity. If water gets into the pipe, it will be worse to warm.

- Resistance to high temperatures. It is connected with the fact that hot water will flow through the pipes, and the temperature in the street will be lower. The material must be resistant to temperature shocks.

- Operating time.

- Easy to install, unpretentious care.

A lot of heaters are used to isolate the external heating system: PVC, mineral wool, plastic and polyurethane heaters, colored pipes made of polyethylene and others. It is not difficult for the buyer to select material for specific conditions for a certain estimate.

The main types of heat insulators

The choice of insulator is influenced by climatic conditions, budget and specific customer requests. Under these criteria, the best option is selected for tubular and roll heat insulators.

Mineral wool

Mineral wool is a popular material for insulation. It has good durability and practicality.

There are several types of mineral wool:

- Made of basalt. It is highly resistant to heat (up to 600 ° C). It does not enter a chemical reaction with pipes, does not emit harmful substances when heated.

- Fiberglass. It is based on quartz sand. It is used only for external decoration of external pipes. There are temperature restrictions - up to 200 ° C.

Mineral wool has a large percentage of moisture absorption, which reduces the insulation properties. To avoid this, waterproofing is mandatory.As waterproof materials, roofing material is used, the sheets of which are wrapped around the trunk. This is the easiest and most convenient way to isolate. For pipes, rolled mineral wool is bought.

Popular brands of materials include Energoflex, Germaflex, Vilaterm and others.

Styrofoam

For the external finish of pipes, a special form of foam is produced, which repeats the geometry of the highway. The most common form is a two-part ring. The material hardly absorbs moisture, but additional waterproofing is still required. The rigid foam shell is excellent on the pipe. Available in gray and blue.

There is a type of foam, which has a high density and water resistance - this is extruded polystyrene foam. Polyurethane foam has a similar composition.

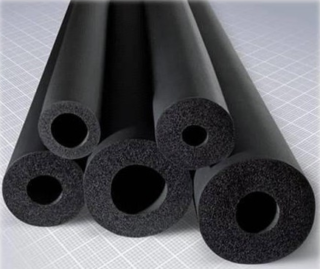

Foamed insulation

For the manufacture of such heaters are used:

- rubber;

- polystyrene foam;

- polyurethane.

The insulation is made in the form of a cover on which there is a cut for ease of installation. After installation, this section must be glued so that moisture does not get inside.

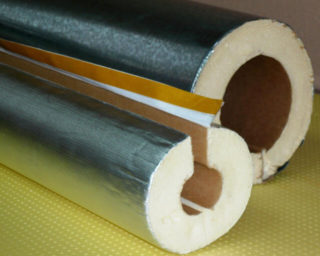

Reflective pipe winding

Penofol is used for the external reflective winding of street pipes. The principle of operation is the reflection of heat from the mirror surface of the insulation. As such material, mineral wool, foam rubber, porilex and other heaters can be used, which must be covered with foil on top. Fixing is carried out on a strong wire.

The main functions of warming pipelines of this kind:

- reflection of warm currents;

- wind protection;

- do not pass cold and moisture.

The most convenient pipe reflective insulation is penofol. It incorporates a warming layer and foil for reflection. Available in various sizes and thicknesses in the form of a cylinder. Foam insulation is less commonly used.

Heat insulating paint

The method of insulation using heat-insulating paint is highly effective with minimal weight. Only a few millimeters of paint is enough to cover the pipe. Allows you to replace the thick layers of other insulation for decoration.

Sprayable insulation

This is one of the best ways to insulate pipes. The process is fast, warming quality and reliable. Due to the absence of seams and joints, the possibility of moisture or wind getting on the pipes is excluded.

The main disadvantage of this finish is the difficulty of installing insulation of heating pipelines. To work, you need a certain work experience and a professional tool.

Pros and cons of insulation

Before choosing a particular type of insulation, you need to familiarize yourself with the positive and negative qualities of each material.

Mineral wool has the following advantages:

- good thermal insulation for pipes;

- resistance to aggressive environmental influences;

- long service life;

- does not decay;

- scares off rodents;

- it is applied to pipes with a high indicator of temperature;

- low cost.

The main disadvantage is hygroscopicity. Corrected by adding waterproofing.

Benefits of Penoizol:

- good thermal insulation of pipelines;

- no waterproofing is required;

- biological stability.

Minus - the need for special equipment for coating. For this reason, such insulation requires large financial investments.

Advantages of Styrofoam:

- low cost;

- tightness;

- simplicity of laying.

The disadvantage is that additional waterproofing is required. It is similar in effectiveness to mineral wool.

The advantages of heat-insulating paint include high efficiency, which is achieved even with single-layer application.It also stands out for its ease of installation and the possibility of use in hard to reach places. Minus limiting mass use - high cost.

Indoor insulation

The need for insulation in the room appears if the room is unheated. It can be an attic, a basement, a barn, a loggia. It should be borne in mind that in such rooms there is a high level of moisture, as well as rodents that can damage the insulation.

Thermal insulation is done without waterproofing, if the room is closed.

To select the material in the attic, you should pay attention to the characteristics. Must be resistant to heat.

Warming outside the house

In the case of insulation of street pipes, a waterproofing layer is required.

Procedure Algorithm:

- laying a layer of mineral wool;

- winding the layer with silk threads;

- laying a layer of roofing material;

- aluminum or galvanized wire for corrosion resistance.

The material for pipe insulation must be suitable for the appropriate climatic conditions, fulfill the declared functions and be resistant to moisture. In the event of water ingress, many pipe heaters lose their properties.