Owners of private real estate have to solve the problems of lack of living space and energy conservation. These issues are especially relevant for the owners of cottages, when they often have to receive many guests and relatives. Proper insulation of the attic will make it comfortable for living at any time of the year with minimal heating or cooling costs. In order to prevent annoying mistakes during construction, you need to familiarize yourself with the properties of commercially available thermal insulation and the technology of its installation. With proper organization of work, it can be done on its own, saving on the services of professionals.

The choice of insulation for the attic

The insulation for the attic should be selected based on its purpose, size, configuration and climatic conditions. You can get a scientifically sound certificate about which insulation is best for the attic roof in SNiP 23-02-2003.

The construction market is full of materials, diverse in form, composition, cost and technical characteristics, intended for thermal insulation of residential premises. To make the best decision of their choice, you should consult with friends and professional builders, study the properties, pros and cons of heaters on sale. Experienced builders recommend warming the attic roof in a comprehensive manner, using different substances for interior and exterior decoration, taking into account their properties, advantages and disadvantages.

Minvata

Minvata is the most popular and demanded material in construction due to its high performance. It is made of glass battle, steelmaking slag and natural stone. The finished product is a spatially interwoven fiber material in the form of mats and rolls with a thickness of 100-400 mm. Since the substance has sufficient strength and elasticity, its main volumetric component is air, which practically does not conduct heat and cold.

Mineral wool has the following advantages:

- excellent soundproofing properties;

- low thermal conductivity;

- ecological cleanliness;

- ease of installation;

- elasticity, due to which no cracks remain in the masonry;

- medium degree of hygroscopicity;

- fire resistance, the ability to create a reliable barrier to the flame;

- almost endless life.

Mineral wool is not ideal for builders, as it also has a number of disadvantages. Quality products from trusted manufacturers are quite expensive. During installation, many tiny volatile fibers are released. When insulating the attic floor with mineral wool, it is necessary to use means to protect the skin of the hands, face, organs of vision and breathing. In addition, moisture absorption leads to a decrease in insulating qualities.

Styrofoam

When deciding which insulation for the attic roof is better, many owners of private houses opt for polystyrene. This is a reasonable preference, since PP has numerous advantages that affect the quality of building insulation:

- low density;

- convenient standard size 100x100 cm;

- low thermal conductivity;

- affordable cost;

- ease of processing;

- long term of operation;

- water resistant.

The disadvantage of insulation is the combustibility and toxicity of the gases released during this process. In addition, the substance is very fragile, care must be taken when transporting and laying it. Since polystyrene is environmentally friendly, insects and rodents like to settle in it. A good, but more expensive counterpart is foam, characterized by flexibility, elasticity and a longer service life. Plates have locks on each side, due to which a tight and durable connection is achieved.

Polyurethane foam

Polyurethane foam is a product of modern technology and is characterized by high performance. It belongs to the category of sprayed materials obtained by mixing two inert ingredients. It is applied using industrial equipment or disposable spray cans (“mounting foam”), which are sold in any hardware store. Liquid substance comes out of the atomizer, which penetrates into the smallest cavities. In the process of foaming, it increases in volume and hardens, acquiring a dense consistency.

Advantages of PPU:

- smallest thermal conductivity among analogues;

- environmental Safety;

- lack of need for external finishing;

- long service life;

- water tightness;

- lack of hygroscopicity;

- high degree of adhesion to any substances.

The main disadvantage is the high cost of polyurethane foam. In addition, specialists of a similar profile may not be in remote regions, and the use of spray cans is a very costly undertaking.

Ecowool

Ecowool is often used when you need to qualitatively insulate the attic for winter living, as the material is characterized by excellent insulating properties:

- the substance is completely natural and environmentally friendly;

- porosity, providing low thermal conductivity;

- light weight, even a thick layer does not exert additional load on the supporting structures;

- the presence of a natural antiseptic (borax), which eliminates the occurrence of mold and fungus;

- filling all voids, which contributes to the absence of cold bridges after application;

- preservation of the original volume.

When deciding to insulate the attic with ecowool, it must be borne in mind that it is combustible, in the absence of quality sealing, absorbs moisture and loses its quality. In addition, the substance of natural origin attracts insects and rodents, who like to arrange their nests in it and exist in them for decades.

Preparatory stage

The insulation of the attic roof is a responsible event that requires careful preparation. You need to pay attention to the choice of tools and materials, as well as safety.

- Check the condition of rafters, floorboards and other structural elements. Reinforce if necessary.

- Make ventilation holes and make channels for venting air from the room.

- Remove from the attic all non-repair items, debris, sawdust, clean surfaces from dust.

- To establish special channels for communications, so that after the attic has been insulated from the inside, there is free access for inspection or replacement.

- To process the wooden parts of the roof frame with an antiseptic, hydrophobic and flame retardant.

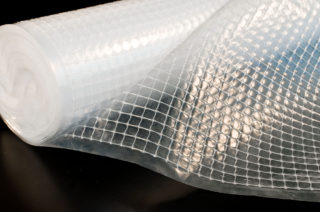

It is necessary to waterproof the surfaces to prevent water from entering the attic from the outside and to ensure the removal of fumes from the inside. A superdiffuse membrane that fits on the outside of the frame is best suited. Inside, it is sheathed with vapor barrier material based on fabric or foil.

Fastening of cloths should be carried out with brackets made of stainless steel or copper. Stripes should be applied with an overlap of 15-20 cm, and the joints should be glued with aluminum tape. The film must be fixed with a sagging of 10-15 mm, so that when the temperature decreases, the vapor barrier does not tear from strong tension during shrinkage.

Step by step instructions for warming

Specialists in the field of construction recommend warming the attic floor comprehensively, on both sides, using a supporting frame to accommodate thermal insulation. This approach will save usable space under the roof of the second level of the building. Before starting work, you need to draw up a styling diagram, calculate the material requirements. You need to take it with a margin of 10-15% to cover errors and damage during transportation.

It is advisable to start insulating the building from the outside. This is justified by the fact that after laying the material on top of it, a roof will be mounted, which will protect the structure from moisture, mechanical damage, ultraviolet radiation and precipitation.

Step-by-step instructions for completing this stage of work:

- Placement of insulation between the rafters. It uses mineral wool or polystyrene. Mats and rolls are cut so that they enter the openings with effort and are held in them due to elasticity. To do this, the width of the blocks is 2-3 cm larger than the openings. Polyfoam is inserted end-to-end, cracks are filled with polyurethane foam, surpluses are cut off.

- Attaching a membrane film, it is needed to remove moisture that enters the walls from the interior.

- Creating the basis for finishing. If a soft coating is selected, the frame is lined with plywood, boards or OSB. For hard materials, a crate is made with an appropriate step. To do this, it is better to use a moisture-resistant metal profile.

The final step is the laying of the roofing. The correct solution is to use materials with low thermal conductivity. For a gable sloping roof, ceramic tiles, facade panels and plastic hollow shields are well suited.

Insulating the roof from the inside, if it is already covered, is not particularly difficult, since it will work in comfortable and safe conditions. In most cases, materials of small thickness are used, performing the functions of decoration and protection from external noise.

It is necessary to equip the insulation inside:

- Bring insulation into the attic. Remove it from the packaging and allow it to mature during the day so that it meets the installation conditions.

- Measure and cut the workpiece to the desired size. Mark them so as not to confuse when stacking. Make similar marks on surfaces.

- Place the insulation elements at the lower level. Subsequently, the finish will be a support for wall insulation. You need to choose the material for the floor in advance in order to make the crate of the proper shape under it. It must comply with the climatic conditions in which the building will be operated. In addition, you need to consider the purpose of the attic. For residential premises, safe fillers should be chosen.

- Install vapor barrier gasket. It is attached with brackets using a stapler. Overlaid edges are securely closed using construction tape.

- Install the rough or fair flooring. For carpet, laminate or linoleum, shields are laid. Polished boards with side locks can be placed directly on the frame.

Then each wall and ceiling are arranged, which are often adjacent elements in the structure. This is done in the following sequence:

- To arrange a frame for a heater.For this, boards or a steel profile are used. Bearing structures are treated against corrosion.

- Filling the cells with insulation. This should be done in accordance with the instructions for use for each material used.

- Insulation of the insulation with a vapor barrier.

- Application of a base for a soft finish, which can be wallpaper, leather or carpet. For hard coatings this is not necessary. Laths and panels can be immediately attached to the frame.

Material for interior decoration must be safe in fire and environmental respects.

Required insulation thickness

The required thickness of thermal insulation can be calculated mathematically by multiplying the coefficient of thermal conductivity of the material by the regional indicator, which is established by analytical calculations. These values are established by analyzing the average annual temperature over the past 50 years.

For the central part of Russia, the following thickness indicators for materials used in construction are optimal:

- mineral wool - 15 cm;

- polystyrene - 10 cm;

- polyurethane foam - 8 cm;

- ecowool - 15 cm;

- expanded clay - 25 cm;

- polystyrene foam - 10 cm;

- a mixture of clay and sawdust - 35 cm.

The numbers are averaged and do not apply to abnormal temperatures.

Common mistakes

Most often, novice masters make the following mistakes:

- ignoring the installation of vapor barrier, which leads to the formation of dampness in the ceilings;

- improper installation of the drainage system;

- installation of a thin layer of heaters, which leads to overheating and freezing of the attic;

- leaving open joints of waterproofing paintings;

- excessive tension of the vapor-permeable film, which leads to its rupture upon cooling.

To avoid mistakes, you need to follow the instructions of the material manufacturers, the recommendations of professionals and the construction plan.