The process of warming any building or structure is an obligatory stage of construction and finishing work, which should be treated as responsibly as possible. Proper thermal insulation helps maintain the optimum temperature in the room, where it will be quite comfortable in winter and summer. For this purpose, it is worth choosing materials from well-known manufacturers, for example, the innovative Rockwool Light Butts insulation manufactured by Rockwool. It is designed specifically for private buildings and structures, has a high level of reliability and is able to perfectly cope with its functions.

Description of Rockwool Light Butts

Light Butts Scandic is a mineral wool insulation, which is made from gabbro-basalt ore. Rock stones are melted at high temperature and the resulting lava is placed in a centrifuge, which allows to obtain special fibers intended for the formation of a Scandic series insulation. It is additionally enriched with water-repellent substances in order to exclude water absorption in the process of thermal insulation.

At the final stage of production, the building material turns into hydrophobized slabs with light weight, resembling stone wool outwardly. In the manufacture, a special Flexi technology is used, thanks to which the edges of the plates can be pushed. The insulation material is able to spring, which greatly facilitates installation on structures with a frame of wood or metal. Flexed edges are marked, a special icon is placed on the end part from the side 1000 mm long and 50 mm wide.

Brand boards are ideal for creating a heat-insulating layer that does not require special loads. They are used in the formation of partitions, attics, floors between floors, walls of buildings with a small number of floors.

The main advantages of the material

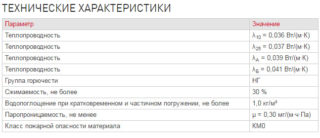

The Rockwool Scandic insulation has an optimal coefficient of thermal conductivity equal to 0.039-0.041 W / m-K, which allows it to retain heat indoors during the winter season and at the same time keep it cool in hot summers. The use of rocks in the manufacturing process gave the material the ability to withstand the highest temperatures up to +1500 degrees. It is ideal also for structures that are subjected to powerful heating. Rockwool mineral wool boards are fire resistant and prevent the spread of fire when exposed directly.

The stone wool from which the slabs are made is of optimal density and passes vapor well, which allows moisture to pass through the material and not linger in it. The material of the brand has a high level of environmental friendliness, confirmed by the EcoMaterialGreen certificate, the insulation is not affected by mold and various fungi, it is not interested in rodents and insects as food. It is resistant to alkalis, acids, solvents or oils that do not damage the fiber board. The list of advantages of Rockwool Butts Light material includes the following properties:

- increased elasticity and resistance to deformation;

- resistance to fire and moisture;

- the ability to compress by 60%;

- good thermal insulation;

- lack of problems during installation and operation, long service life;

- increased environmental friendliness.

Thanks to its thoughtful composition, the material also provides good sound insulation.This property allows you to use it not only as a heater, but also as an additional noise insulation layer.

Specifications

The Rockwool insulation of the Light Butts Scandic series is recognized as unique due to its ability to restore structure and shape. During production, the air is completely removed from the packaging material, which allows the packaging to take up 70% less space compared to the actual size of the plates. The material is presented in two sizes - standard and XL x x with dimensions of 80x60 and 120x60 and 10 cm, respectively, so it can be transported both in cars and in trucks. The width of the plates is 5, 10, 12.5, 15 and 20 cm, they can be cut into pieces and use suitable pieces during installation.

The Rockwool insulation of the Light Butts Scandic series is recognized as unique due to its ability to restore structure and shape. During production, the air is completely removed from the packaging material, which allows the packaging to take up 70% less space compared to the actual size of the plates. The material is presented in two sizes - standard and XL x x with dimensions of 80x60 and 120x60 and 10 cm, respectively, so it can be transported both in cars and in trucks. The width of the plates is 5, 10, 12.5, 15 and 20 cm, they can be cut into pieces and use suitable pieces during installation.

The thermal conductivity of the material ranges from 0.036-0.041 W / m-K, depending on the size of the miniplates. The presence of edges processed by Flexi technology allows you to quickly and easily install plates in all types of frames. Slabs from Rockwool differ in their elastic structure, since the fibers in them are located horizontally and vertically. It should be borne in mind that the material should not be subjected to strong pressure, since it is used only for structures with minimal load. It must also be remembered that with constant heating, the life of the plates decreases.

The material is not used to protect against excess noise, its main purpose is to keep warm. But thanks to the optimal absorption of sounds up to 60 dB, it has additional properties and can also be used as a means to suppress noise. This is true for those who use it to insulate floors and frame walls. In general, buyers leave positive feedback on the brand’s minplits, but note their high cost, which is almost the only drawback.

The price of one square meter of a plate 50 mm thick will be approximately 95 rubles. It must be taken into account that the material is laid in several layers; therefore, its quantity in pieces should be calculated in advance.

Application area

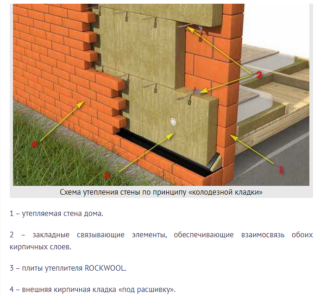

The insulation from the Rockwool Scandic series is most often used to insulate external walls. The best choice is the technology of the ventilated facade, which ensures perfect steam exchange, which ultimately helps prevent the walls from getting wet and choose any decorative coating for the facades. Good technical characteristics of the material make it possible to use it as a heater for two-layer brickwork. Typically, builders erect a wall in two layers according to the principle of well masonry, placing material between the layers.

Plates can also be used in frame construction, laying a layer of insulation between sheet or piece material in the basis of a wooden frame. The material will also be useful to those who plan to finish the walls of the house using the “wet facade” technology, it is used for both external and internal wall insulation, if necessary. Rockwool insulation from the Light Butts Scandic series is suitable not only for walls, but also for floors and floors, for example, for the purpose of warming basements without heating or cold attics.

With its help, effectively insulate the floors on the logs or under the screed. The versatility of the material allows it to be used for attics and roof structures, including for the purpose of warming pitched and flat roofs. Owners of baths and saunas that require special thermal insulation can use stoves in order to maintain optimum heat and prevent high humidity in the walls.

Plates in combination with additional materials are suitable for technological equipment and the construction of soundproof structures.

The versatility of Rockwool boards allows them to be used in any type of construction and to successfully insulate them with walls made of various materials. This is the best choice for both professional builders and owners of private buildings.

Mounting Features

During the installation of mineral plates, experts advise observing the manufacturer's recommendations so that the service life of the material is extremely long. Insulation must be laid in at least two layers, overlapping joints. Due to the presence of springy edges, the process of placing the plates is greatly simplified, they do not need to be trimmed or sized. After installation, between several rafters or other guide elements, the material straightens and fills an empty space. It is not so difficult to identify the marked side, as it is marked with a red stripe.

During the installation of mineral plates, experts advise observing the manufacturer's recommendations so that the service life of the material is extremely long. Insulation must be laid in at least two layers, overlapping joints. Due to the presence of springy edges, the process of placing the plates is greatly simplified, they do not need to be trimmed or sized. After installation, between several rafters or other guide elements, the material straightens and fills an empty space. It is not so difficult to identify the marked side, as it is marked with a red stripe.

Brand plates must be additionally protected from direct exposure to water and condensate, for this purpose layers of a special membrane are used, which are laid on top of the mineral wool. Most often, a membrane from the same manufacturer is used, for example, Extra. It is necessary to put it with an overlap, gluing the joints between the layers for greater tightness. Slabs must not be left open, otherwise stone particles and fibers can get into the room. They are additionally covered with a vapor barrier film, siding lining, sheets of plywood or drywall.

In the process of work, personal protective equipment is always used: glasses, respirators, gloves and protective clothing.

Most often, the plates are installed in their entirety, but sometimes fragments may be required; in such cases, the material is cut with a knife. During installation, it is recommended not to compress the plates over the entire surface, it is better to do this only from one edge, so as not to reduce the effectiveness of the insulation. Each plate is installed on a pre-prepared frame, greatly simplifying the entire installation process.

For frames, structures made of wooden bars or metal profiles of standard sizes are used. During the installation of interior partitions, experts recommend making the frame vertical to reduce noise. If installation work is carried out in accordance with all the rules, the panels will reliably protect any room from heat, noise and sound losses, help reduce the load on the supporting structures and extend the life of any structure.

Minvata is complemented by hard edges to prevent fiber loss. At the same time, all the edges are able to dock well with each other, which eliminates the cold and drafts in the finished structures.