Modern Kermi radiators are a product of a well-known German manufacturer, which is part of the AFG-AG association. Thanks to a well-thought-out design and high quality products, demand for them for many years is maintained at a high level. The advantages of Kermi batteries require a more careful study of their characteristics and installation features in residential premises.

Description of the manufacturer

The founding date of the German company Kermi is 1960. The main profile of her activity is the production of panel-type heaters and modern showers. A distinctive feature of Kermi heating radiators is the presence of two connection methods, as well as various design options. In addition to standard steel structures, the manufacturer offers relatively inexpensive bimetallic products.

A characteristic feature of German radiators is a high level of heat transfer that exceeds that of other well-known manufacturers. It can be achieved due to the high efficiency of heat transfer processes occurring inside the heating system. Kermi heating radiators are ideal for installation in autonomous highways with low working pressure (in a cottage or a country house, for example).

Sizes and types of batteries

A user who decides to purchase a Kermi battery will have a difficult choice in choosing an appropriate model. This is because a significant variation in performance requires a detailed study of the technical characteristics of each of the proposed products. Particularly noteworthy is such a specific parameter as the dimensions of the case, which vary widely.

- the length of known models ranges from 40 cm to 4 meters;

- height is from 30 to 90 cm.

In addition, steel heating batteries from Kermi differ in their design and can be simple tubular, panel, or have many transverse ribs. The second option, in turn, is divided into units that include one, two or more panels.

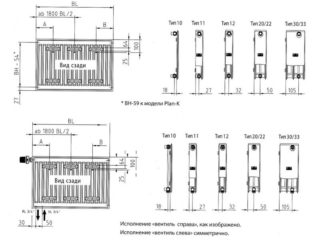

By this indicator, several types of radiators are distinguished, differing in the number of sections used. All of them are summarized in the table and marked with the corresponding numbers. In the composite catalog, in the form of a special designation, not only the number of constituent elements is encoded, but also a number of additional characteristics. The code 10 means one panel, and 11 - its kind with an indication of the ribbed structure. The batteries under code 22 include products with two panels and double ribbing.

Kermi panel radiators can have a corrugated (Profil category) and smooth surface. The second variety is designated as “Plan” and also has various designs that differ in characteristics and generally accepted marking. The Plan-V series, for example, is referred to as FKO and represents products with a lower eyeliner. Most buyers know them in the following three forms:

- left-handed;

- right-handed;

- centered.

Models from the Plan-K group of the FKV standard marking have side connections.

The group of smooth heating devices of the V series also includes special “hygienic” models that do not have additional fins and covers. This type of radiator is designed for installation in medical institutions, as well as in the locations of people suffering from allergic diseases.

Another non-standard version of Kermi heaters is Verteo Plan or FTV.They are products of a vertical type, in demand in situations where the installation of horizontal analogues is impossible. These samples have a “classic” lower eyeliner and can be integrated into a hidden pipe system. In addition, the supply pipes for these products may be laid under the floor finish. The inner and outer surfaces of the radiators are protected by two layers of high-quality varnish.

Benefits of Kermi Radiators

Branded models from the German company Kermi, regardless of their variety and type of connection, differ in the following advantages:

- Attractive design and operational reliability

- high rate of heat transfer;

- the use of quality materials;

- the ability to select a convenient sample for operation with the desired type of connection (side or bottom feed).

To give the metal base additional strength in the manufacture of it is subjected to treatment with iron phosphate. In addition, a special protective dye is additionally applied, which is closed on top with two layers of varnish. This approach allows you to extend the life of the German radiator, as well as provide it with an attractive appearance.

Power calculation

One of the options for calculating the power of the radiator involves the use of a comparative method, when a typical cast-iron 12-cell battery is taken as the basis. From the studies carried out it is known that with such dimensions it provides heat transfer of the order of 1444 W.

One of the options for calculating the power of the radiator involves the use of a comparative method, when a typical cast-iron 12-cell battery is taken as the basis. From the studies carried out it is known that with such dimensions it provides heat transfer of the order of 1444 W.

The capacity of the internal volume of the cast-iron sample filled with coolant is 13 liters.

From the Kermi battery passport, it is easily recognized that the heat transfer from a typical single-section unit under code 10 is about 2100 W (with a working volume of 6.3 liters). Using these data when replacing cast iron batteries with new samples, you can be sure that their heat transfer will not be worse, or even slightly higher.

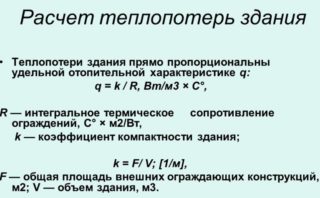

For the correct determination of the required power and the connection diagram of the radiators, a tabular calculation option is used. For its implementation, the following additional data will be required:

For the correct determination of the required power and the connection diagram of the radiators, a tabular calculation option is used. For its implementation, the following additional data will be required:

- the amount of heat loss in the apartment;

- liquid carrier parameters;

- estimated indoor temperature average.

When choosing, the dimensions of the radiator are also taken into account, after which corresponding adjustments are made to the selection algorithm. The desired value of thermal return is determined by the summary table provided by the manufacturer of a particular radiator from the popular Kermi line. The desired model is located in the corresponding column, opposite which the power value suitable for it is indicated. Experts advise taking this indicator with a small margin, which guarantees the desired result.

After all parameters have been taken into account, the user will be able to more accurately determine the model suitable for specific operating conditions.

Connection Features

Mount Kermi radiators is not at all difficult, especially if you take into account all the nuances of the upcoming work in advance. If you do not plan to change the existing wiring diagram, it is important to provide for the possibility of its connection with the input and output nozzles of the battery. With different sizes of pipes and radiator working holes laid in the apartment, special adapters will be required.

To identify the features of installing a new heating system, it is recommended that you immediately read the instructions for its installation. After all the nuances are taken into account, you can proceed directly to the procedure for connecting radiators. At the same time, one should not forget about the presence of two connection options, according to which it is lower and lateral. Each of these methods has its own characteristics.

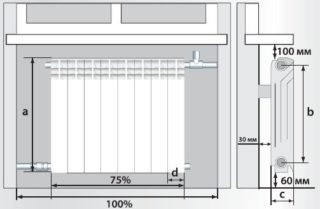

Before installing Kermi radiators with a lower connection, for example, it is important to determine the place of their installation, chosen taking into account the following requirements:

- the distance from the floor should not be less than 100-120 mm;

- the location relative to the windowsill is no closer than 80-100 mm.

Compliance with these requirements guarantees the convenience of piping, and also ensures maximum heat transfer.

Correct positioning of batteries with any type of eyeliner contributes to an even distribution of heat throughout the room.

Another feature of these products is that they are delivered with all the necessary components for installation, which includes:

- mounting brackets (hooks);

- corner clamps;

- upper protective grill;

- covers and sidewalls in the form of caps.

The same kit includes thermostat and Maevsky bleed valves, but not for all types of products supplied.

The order of installation and connection of radiators with bottom connection:

- At the selected location, the marking of the bracket points is applied.

- They are securely fastened using the hardware supplied with the kit.

- Upon completion of this operation, the radiator is hung on hooks and leveled.

- After that, it connects to the pipe system (including return pipe).

The last procedure is carried out in accordance with the scheme in the manual.

At the final stage of work, the system is tested for leaks. This operation will require the help of professionals who have at their disposal special testing equipment.