Regardless of the type of modern solid fuel (TT) boilers, they all have a high efficiency, which can be achieved by the design features of the units themselves. This is facilitated by the solid fuel combustion mechanism implemented in them, which differs somewhat from the traditional method. Knowing these features will allow you to understand how the long-burning boiler (CDG) works, as well as get acquainted with its advantages and disadvantages.

How do KDGs work?

In most solid fuel furnaces, the upper supply method of the oxidizing agent (oxygen contained in the air) is used to maintain combustion. In addition, immediately before it enters the furnace, it is heated to a certain temperature, which contributes to better oxidation and minimization of combustion waste: ash, soot, etc.

In most solid fuel furnaces, the upper supply method of the oxidizing agent (oxygen contained in the air) is used to maintain combustion. In addition, immediately before it enters the furnace, it is heated to a certain temperature, which contributes to better oxidation and minimization of combustion waste: ash, soot, etc.

Oxygen in them, unlike a fireplace, is supplied from the upper entrance, and then lowers into the lower part of the combustion chamber.

Thanks to such an organization of air movement at the initial stage, only the upper layer of solid fuel placed in the chamber volume is effectively burned. After the reserves of this layer are running out, the supply of oxygen to its lower part is turned on. As the next layer burns out, the air stream penetrates deeper and deeper into the furnace. Due to this, each subsequent wood portion is utilized only with the advent of its order.

This approach allows you to save on the amount of fuel consumed and at the same time clearly control the combustion process. The described features of the technology made it possible to attribute the boilers operating on its basis to the category of heating equipment for long burning. Due to the specifics of operation, these units are economical and guarantee a high level of environmental friendliness when disposing of all types of fuel.

Advantages and disadvantages

The advantages of long-burning boilers include:

- efficient use of the combustion chamber - this is achieved due to the fact that the fuel inside the unit does not burn, but smolders slowly;

- high efficiency (COP), which in some samples is close to 85%;

- significant volumes of the loading chamber;

- the ability to work on one tab of solid fuel longer than 12 hours;

- the possibility of concentration of heat within the boiler, which allows heating significant spaces.

In most KDG models, up to 50 kg of fuel is allowed at a time, so owners of boiler products are exempted from the need to constantly add firewood to the furnace.

There are no complaints from users regarding the performance and quality of the equipment. The only problem with the decision to purchase it is the high cost of the heating complex - from 100,000 rubles. If you purchase a not very prestigious and cheap unit, no one can guarantee the high quality of such a “stove”.

Fuel used

The advantages of heating equipment for long burning include the possibility of using various types of fuel, which allows its owner to choose the most economical type. The following types of solid fuel are suitable for loading into the KDG:

- firewood or coal;

- natural peat and artificial pellets;

- conventional or pressed sawdust.

The dimensions of the combustible billets laid in the chamber can be different, which simplifies the procedure for their storage within the boiler room.

The ability to use a variety of types of solid fuel once again confirms the versatility of automatic boilers, which are allowed to be used in domestic conditions.

Calculation of the required power

To determine the performance of the purchased boiler, you will need to thoroughly prepare and take into account the following indicators:

- the area of heated premises in the country or in a private house;

- quality of insulation of the walls of the building;

- type of constantly used fuel;

- the number of thermal circuits for heating the house.

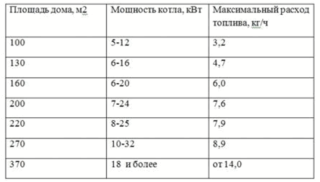

After preparing all the data listed, including the detailed drawings of the circuits, the calculation of the required boiler power for heating a private house will be significantly simplified. In this case, the known ratio will help, according to which per 1 square. a meter of space will require 1 kW of usable power. The indicated rule is valid only if the height of the ceilings in the building does not exceed 3 meters.

For the convenience of determining this indicator, special tables have been developed in which sufficient capacity for its heating is assigned to a room of a given area.

Features of choice

Before choosing the right KDG model, you should carefully familiarize yourself with the characteristics declared by its manufacturer. In addition, it is important to consider the following details regarding the technical characteristics of the purchased product:

- number of water heating circuits;

- power provided - it cannot be less than the indicator obtained by calculation;

- the dimensions of the boiler, allowing it to be installed in any corner of the room convenient for these purposes;

- type of solid fuel used.

When buying, it is important to inquire about the availability of a certificate from expensive equipment and find out the period of warranty provided by the manufacturer.

Safe operation

For the safe operation of solid fuel boilers for long burning with a water circuit, the following conditions will need to be observed:

- the flooring under the door of the combustion chamber must be closed with a steel sheet 700x500 mm in size;

- on the surface of the wall adjacent to the boiler body, a layer of plaster 25 mm thick, hardened with a metal mesh, is applied;

- the distance from the furnace door to the wall closest to it is at least 125 cm;

- if it is impossible to fulfill the last two requirements, a steel sheet or an asbestos blank of 8 mm thickness is mounted in this zone - their upper cut is 25 cm above the boiler level.

The gap between the floor and the bottom of the ash pan is selected taking into account the characteristics of the overlap. If it is made of combustible material, this distance should be about 14 cm; otherwise, the bottom is left at floor level. The issues of safe handling of heating equipment also include the rules of ignition of the boiler and its loading, which are described in detail in the user manual.

Rating of popular manufacturers

A large number of KDG of domestic and foreign production are presented on the Russian market. But only some of them meet the requirements for these units, including reliability, durability and ease of use. When compiling a rating of solid fuel heating boilers for a private house, a number of certified models were used, the quality of which is confirmed by many users.

On the first place Products from the Russian company are located NMKdistinguished by an extensive assortment and a large selection of prices: from 30 to 100 thousand rubles. With their help, it is possible to heat rooms from 50 to 3000 square meters, as well as bath rooms (steam rooms) up to 30 cubic meters. All boilers from this manufacturer are certified, their characteristics comply with international standards.

Second place confidently occupied by the Lithuanian manufacturer with the brand Stropuva. Solid fuel equipment from Lithuania is able to sustain combustion for 3 days. At the same time, constant supervision by a person is not necessary at all. The design of boilers from this manufacturer allows for more than 50 kilograms of firewood to be placed in the working chamber in one load. At the same time, the declared power of the unit exceeds 40 kW, which is quite enough for any country house. One of the examples of solid fuel boilers manufactured by Stropuva is a model called Candle. Its advantages include:

- the ability to work on wood for 2 days, and on coal - more than 5 days;

- high performance indicators (efficiency - up to 94%);

- admissibility of incorporation into a system with natural (forced) circulation of the coolant.

A distinctive feature of Candle products is the ease of use of the equipment. All that remains for the user to do is to periodically add portions of fuel, and also at least 2 times a month to clean the furnace of accumulated ash.

Honorary third place occupied by one of the leaders in the Russian heating equipment market - a company called "Week". The company is engaged in serial production of heating boilers with a capacity of 15 to 90 kW. Models of this brand warm rooms with a total area of up to 400 square meters. meters and are able to work autonomously for about a week.

Fourth place confidently takes a well-known German company Buderus, whose products are of high quality and enviable indicators of durability. All units of the Buderus brand are characterized by a thoughtful design, the use of high-quality materials, as well as their versatility.

In addition to the above list, the attention of users is often attracted by solid-fuel pyrolysis boilers of long burning "Cosmos", equipped with doors with interchangeable hinge. Another noteworthy model is the Prometey-12M-5 solid fuel unit, well known to most Russian buyers.

A modern solid fuel boiler with a water circuit is a high-tech and difficult to assemble equipment, which is notable for a rather high cost. However, only professionals with extensive experience can make it with their own hands. At the same time, it is impossible to exclude the possibility that a home-made boiler will not allow achieving the required heating efficiency of rooms in a private house.