The home appliance market offers a wide selection of heating appliances. These include induction boilers, whose popularity is growing rapidly. They account for about 30% of all electric boilers. There are different types of induction heaters that are suitable for heating homes, shops, warehouses and other facilities. You need to familiarize yourself with the features and design of each type in order to make the right choice.

Boiler device

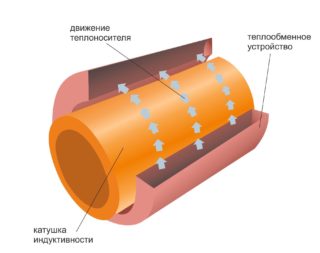

An induction boiler is an electric heater that can generate heat and heat a room thanks to electromagnetic induction. For this, there is a coil and a core inside the device. With the passage of electric current, an electromagnetic field appears. As a result, currents are generated that heat the core, the energy from which is given to the coolant. Its principle of operation is similar to an induction heated floor.

The induction boiler consists of two parts. In the first, where the core and inductor are located, a magnetic field is formed. In the second part there is a heat exchanger with a coolant, in the role of which is ordinary water or another liquid, depending on the model of the boiler. What kind of fuel is needed, you can see in the documentation for the device.

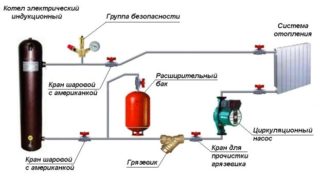

In the heating circuit of such devices there is always a closed circuit. The wiring diagram also includes a container for excess water that appears from thermal expansion. The resulting liquid is then drained.

Specifics of application in the heating circuit

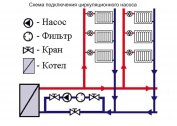

The devices are designed for installation in a system with forced circulation, therefore, the circuit always has a circulation pump. For control, automation elements are used - temperature sensors, temperature controllers and other devices that ensure operability and safety.

Depending on the power, the boiler can be connected to a 220 V or 380 V network. The connection can be single-phase and three-phase. It is also necessary to choose the correct cross-section of wires for the load, so that the boiler works correctly. Powerful devices are additionally equipped with personal protective equipment.

The user independently chooses the temperature regime, which is comfortable for him. The boiler heats up to a predetermined temperature value, automatically turns off and when it falls below the specified temperature it turns on again. Thanks to the continuous cycle in the house, an optimal microclimate is ensured.

Varieties of induction boilers

The principle of operation of all induction boilers is the same. They differ only in their design. There are 4 types - shell devices, with a volumetric and tubular heat exchanger, as well as inverter ones.

Casing boiler

The design of such a device has a casing in the form of a cylinder. An inductor is placed in it. Heat exchange occurs inside and out. The liquid enters the pipe, passes through the heat exchanger, heats up and passes to the heating circuit.

The production of enclosure devices in Russia is handled by the NPK INERA brand, also known as SAV.

Volumetric heat exchanger boiler

The second name of the models is inductive-conductive. It has a cylindrical body made of metal, in which a coil with a ferromagnetic rod is located. It acts as a heat exchanger.

The factory is engaged in the manufacture of "Alternative Energy". Presented by a series of WINES.

Boiler tubular heat exchanger

These are classic induction boilers in which the heat exchanger is made in the form of a set of pipes. They go around the coil. They are considered the first variety of such devices that appeared on sale.

Inverter boiler

In heaters with an inverter, the direct current from the battery is converted to alternating high-frequency. Then the received current passes to the inductor. This solution allows you to get eddy currents that generate heat in the absence of power from the network.

- With inverter

- Inductive Conductive

- With tubular heat exchanger

Mounting Features

In the set, a passport with a drawing and a detailed description of the connection method, characteristics and operating conditions is attached to the induction heating electric boiler. It is recommended that installation personnel be familiar with connecting boilers. In case of defects during installation, the heater may be removed from the warranty. If there is no self-confidence, you should contact a plumber.

The heater can be integrated into an existing heating system as a primary or secondary device. The installation site is selected in advance taking into account the operational characteristics of a particular device.

According to GOST, the induction electric boiler must be grounded. The device itself is installed at a distance of at least 80 cm from the floor and ceiling. There must be a distance of at least 30 cm between the unit and the wall.

Advantages and disadvantages

Heaters gained great popularity due to their positive properties. Induction devices are notable for their safety, including fire, ease of installation and operation, as well as a high degree of heating of the room.

The main advantages of an electric boiler include:

- High efficiency. Higher than other electric boilers. Reaches 98-99%. The heat carrier heats up in about 7-10 minutes.

- The constancy of energy characteristics.

- Minimum heat carrier requirements. Ordinary water can play its role.

- Reliability of work. The design is simple, without complex components. Installed sensors allow you to quickly find and fix problems.

- Long service life. Devices without power reduction are able to work for 30 seasons.

- The possibility of battery life.

- Easy installation. You can install according to the instructions yourself.

- A wide range of. You can find appliances for heating a small house or for a building with a large area. Induction electric boiler can be selected for a summer residence, apartment, store, warehouses.

- Process automation. The device turns on and off automatically, a person with his own hands only sets up and selects modes.

- The heat carrier is heated to 95 ° C.

- Work safety.

- No ongoing maintenance required. This saves money.

- The small sizes. It can be installed even in a small room.

- Undemanding to maintain. No need to clean the pipes, as in other types of heaters, as well as to remove scale from the heater.

Disadvantages:

- The high cost of the boiler itself. It is associated with the use of expensive materials and the complexity of the production process.

- Great weight. Due to the presence of steel parts, the mass of some models reaches 40 kg.

- Noisy work. Can be eliminated using sound absorbing pads.

Subject to operating conditions, the device will last for many years, while the user will save money on maintenance.

Selection recommendations

When choosing any electrical device, the main criteria will be the load and properties of the device itself. It depends on them how the boiler will heat and how much per month you need to pay for electricity. For heating 10 sq.m. with a ceiling height of up to 3 meters, 1 kW of energy is needed.Based on these values, the required load for the heater is calculated. For a house with an area of 100-150 sq.m. need a unit with a load of about 13 kW. In advance, you should select the appropriate wires and take care of a separate high-voltage line for connection.

When choosing, it is necessary to take into account the individual characteristics of the room itself. The presence of insulation, the material of the walls affect the characteristics of the selected boiler. If these parameters are not taken into account, the owner will overpay for the wasted power or freeze from lack of heat in the house.

It is necessary to pay attention to the power factor. According to this indicator, you can determine how much electricity is spent on heating the coolant and how much to create a magnetic field. Its value lies in the range from 0 to 1. The optimal indicator is 0.97-0.98 kVA. In this case, almost all the energy goes to heating the liquid, there is no financial cost for unused electricity.

Many well-known brands are engaged in the production of induction electric boilers. Quality products can be found at domestic and foreign manufacturers.

When buying, it is important to inspect the device for defects. All components must be in the kit. What exactly should be included, can be found in the instructions for the electric boiler. There should also be a passport of the device indicating all the characteristics and a manufacturer's warranty.