The efficiency of its operation, including the safety of people using the unit, depends on the correct manufacture of the boiler strapping as a storage tank. The most important element of the control system of its operation is the safety valve for the boiler, mounted in the cold water channel and performing a protective function. Finding out where the check valve is placed on the water heater and how it is mounted is a priority for owners of heating equipment.

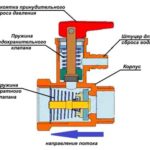

Trigger principle

In the presence of an emergency valve in the supply of cold water, it is possible to prevent the pressure of the liquid carrier from rising above the limit value. It is possible due to the expansion of the water entering the boiler and the increase in liquid volume. Given that the boiler is a sealed device, there is nowhere to go for excess liquid, since one more is put on the supply - a non-return valve. When heated, the pressure in the unit increases and reaches its limit. To prevent the tank from breaking at all, you need a pressure relief valve for boilers.

A logical question arises: why install it, when you can remove the check valve. The inadmissibility of this option is explained as follows:

- The pressure in the water supply system is not particularly stable.

- Situations are possible when hot water almost stops flowing from a tap - its pressure is too low.

- It is displaced into the supply channel of the water supply system, and the heating elements heating it are exposed and quickly burn out.

Burnt heating elements - this is not so bad. It is much more dangerous when they heat up with a simultaneous increase in pressure in the system. The water that gets on them after heating evaporates with a sharp expansion effect, leading to rupture of the flask. Boiling water and steam escaping and can cause personal injury. The principle of operation, which consists in relieving excess pressure in the system, will avoid a serious accident.

Types of valves

By the mechanism of their action, the bypass valves are divided into the following types:

- spring;

- lever;

- magnetic spring;

- dumping.

- Lever

- Magnetic spring

- Dump

- Spring loaded

In the first samples of check valves on the boiler, the main working element is a spring, and in the second there is a lever built in that controls the state of the system in test mode. Models of the magnetic spring type are classified as combined devices that combine the advantages of field and mechanical structures.

Depending on the type of locking mechanism, the following types of check valves are distinguished:

- lifting type;

- swivel and ball;

- interflange.

- Wafer

- Ball

- Lifting

- Turning

The disk plate in the first models moves up and down. After the pressure appears in the forward direction, the shutter opens, and in the event of its disappearance or weakening, it closes due to the spring or its weight.

The device is triggered to close and holds the pressure also when the direction of fluid flow changes.

The rotary or irrevocable variety is made in the form of a flap that rotates and opens under the pressure of a liquid. To close it, the force of the spring is used.

Ball execution is understood as a mechanism in which the fluid flow is blocked by a ball pressed against the saddle by a return spring. The pressure of the liquid in the other direction pushes the ball in the opposite direction, opening a passage for it.

The design of the interflange valve is similar to the lifting mechanism, but in it the plate moves in the direction of flow. Its modification contains two flaps folding towards. The double-wing open structure has minimal resistance to fluid flow.

If the valves are classified by the material from which they are made, the following options are distinguished:

- Brass products characterized by reliability and wear resistance. They are most often used in everyday life.

- Cast iron valves are very inexpensive devices that have one characteristic drawback. They are not protected from rust in any way and are installed only on pipe lines.

- Corrosion-proof mechanisms, which are high-quality and reliable products that have a high price.

It is advisable to use the latter samples only on especially critical sections of pipelines.

By the method of fixation on a working object, all water return valves are divided into the following types:

- Clutch mechanisms installed in the pipe gap by means of two threaded couplings of the appropriate size. This variety is most common in everyday life, in some cases it is used in production.

- Flange devices, where the shutter mechanism is connected by means of connectors of a special design. They are most often used in combination with cast iron counterparts on large pipes.

- Shut-off valves installed between two flanges, which are tightened for strength through studs. This variety is most often installed on the same trunk pipelines.

Installation locations

In domestic water supply and heating systems, there are many sections and runs where it is allowed to mount a safety valve.

- On a branch to the apartment or the private house from the centralized line of supply of hot water (GVS).

- After the fluid flow meter, providing protection against water hammer.

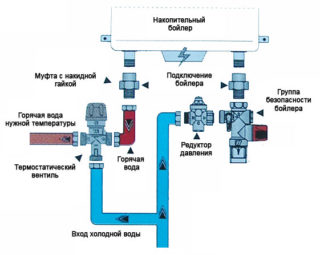

- At the inlet of a gas or electric water heater (boiler), which avoids the outflow of heated and expanded water into the main with cold water.

Protective elements are installed in places provided for by their design features and direct use.

DIY installation

Fuses are selected according to the pressure for which the unit protected from emergency situations is designed (it is given in the passport). The choice is influenced by the tank volume declared in the specifications, in accordance with which the response limits are designed for 6, 7, 8 and 10 Bar. Its installation is simple: a little FUM tape or oiled tow is wound on the thread, after which the product itself is wound on a working pipe. The appliance is wrapped manually until it stops, and then two more turns are made with a key.

The procedure is as follows:

- The location for installing the adjustment device is determined. It is selected depending on what water the valves should be placed on the water heater - most often on the cold water.

- The presence of a ball valve is taken into account - it is needed to empty the tank before winter conservation.

- The faucet for the boiler is often placed on the side of the tee mounted directly on the inlet pipe.

From below, a safety flap valve is screwed to it.

Testing

To check the serviceability on the valve product, a lever for dumping excess pressure is provided. With the heater turned off, raise the lever several times to release these surpluses. After the water stops dripping, wait for the moment until heating starts. If the fluid does not stop flowing, the spring mechanism is most likely clogged. In this case, the collapsible model is dismantled, cleaned, and then put in its original place. With a non-separable valve, it will need to be replaced with a new, previously purchased sample.

It is much worse if the water does not reach the inlet pipe. The reason for this is the appearance of blockage in the valve itself or in the outlet fitting. After checking these places in the absence of a result, you will have to replace the product.

Breakdowns, their causes and elimination

There are two options for failure: water flows all the time or stops flowing completely. If any of them is detected, it is important to consider that bleeding the liquid during its heating is normal, and the system is supposed to work like that. It is allowed to lower it with an idle boiler.

For example, the valve mechanism is designed for 6 Bar, and the pressure directly in the water supply is 7 bar. Until it drops, the water will gradually bleed. If the situation repeats, you will need to change it or install a gearbox at the entrance to the apartment or house.

Compact models of reducers can be mounted at the inlet to the boiler.

Replacement Options

In some cases, instead of the safety valve for the boiler, its "subversive" analogue is installed, intended exclusively for emergency discharge of the liquid used in the heating system. Despite the fact that the functions of the two modifications are similar, by the principle of action they differ radically. Such a mechanism works only in emergency situations, since its main purpose is volley discharge of large masses of liquid. For the gradual bleeding of small portions of water due to the opening of the channel, it is not suitable. Accordingly, such a pressure regulator will not operate normally.

Another solution to the problem is the installation of one check valve, which does not allow water to flow quietly when the pressure in the pipes decreases. However, in this case, the installed protective mechanism does not save from an increase in pressure inside the boiler. This approach is completely inappropriate and inoperative.

Check valve - a mechanism without which the operation of any water supply system is impossible. If it is available, the efficiency of the heating boiler and its safety for humans will increase. In addition, the service life of the heating system is increasing.