Autonomous heating system provides savings on the coolant, reducing installation costs. In order to reduce fuel costs and heating efficiency, it is advisable to connect a gas boiler Proterm Cheetah. Products of the Slovak brand are distinguished by quality, reliability, an extensive model range and ease of installation.

Options and operating principle of gas boilers Protherm Gepard

A standard wall-mounted unit with two circuits is equipped with the main components, software and hydro group. The main elements of the boiler include:

- expansion capacity of the membrane type;

- a sensor that monitors the parameters of water in the pipes;

- hydraulic mechanisms;

- block with an electronic board;

- burner with electric ignition system

- electrode protection;

- boiler;

- turbine for turbocharged models;

- coaxial pipe and distribution adapter.

The hydrogroup is represented by:

- protective fuse-valve at 3 atm .;

- pressure controller;

- stainless steel plate secondary boiler;

- automatic air vent;

- valve switchable in 3 positions;

- a pump for supplying fluid to the circuit;

- gas valve type SIT.

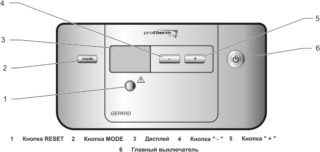

The system is controlled using the LCD monitor, which displays the main parameters. Built-in diagnostics determine the error code. The branded software allows you to operate the heat-power device in the “Eco” modes (heating the coolant to 50 degrees) and “Warm floor”.

Principle of operation

A dual-circuit apparatus with a turbine can be connected to heating and domestic hot water systems. The water is heated by a plate heat exchanger. Fuel combustion products are discharged through a coaxial chimney. The oxygen intake for the combustion reaction is carried out through forced circulation.

The gas burner with modulation allows you to choose the power of the flame when heating water and coolant. At the moment of opening the valve for hot liquid, the power indicator increases and switches the mode. Work parameters are set by the user. In the future, they can be changed automatically or adjusted mechanically.

For effective heat transfer to the closed heating, an additional circulation pump is additionally connected.

Specifications

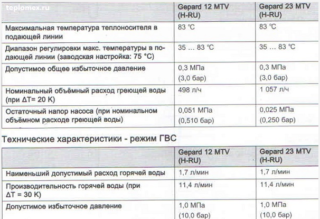

Each Gepard boiler is distinguished by its individual parameters. Despite this, we can highlight the general technical features:

- mounting method - floor or wall;

- fuel used - main or liquefied gas;

- Efficiency - from 90 to 107%;

- power parameters - from 12 to 150 kW;

- the possibility of heating water with a boiler of various capacities;

- the presence of protection systems from overheating and frost;

- equipped with an integrated circulation pump;

- electronic type control system with manual settings.

All gas units are operated in the "Summer" and "Winter" modes.

Pros and cons

Cheetah brand boiler equipment has several advantages:

- cast iron heat exchangers - the characteristic heat capacity of the material ensures the quality of heating;

- maintaining a comfortable temperature for a long time;

- the presence of automatic control mechanisms;

- build quality and many features;

- extensive lineup;

- accessibility - devices belong to the middle price segment;

- availability of self-diagnosis options with error code output;

- compatibility with Russian climatic conditions.

Among the minuses are called:

- a drop in the temperature of the heating main with an increase in hot water consumption;

- warranty service only when installed by Cheetah specialists;

- high gas consumption when turned on at minimum power.

The boilers are universal - can be installed in a private house, utility room, in the workplace.

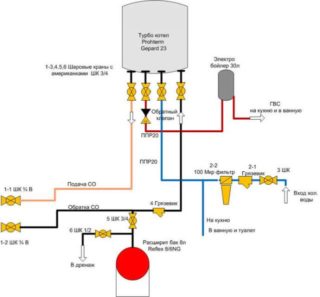

Rules for installing a gas boiler

The use of boiler heaters is a closed system with a forced type of circulation, which works to heat the room and domestic hot water. When installing structures, it is required to comply with the manufacturer's technical regulations:

- Choosing the distance from the boiler to the surface. Wall models are removed 50 cm from the ceiling and 80 cm from the floor.

- Mounting a 3 mm thick metal sheet on a wall for equipment.

- Electrical cable preparation and grounding line organization.

- Drilling holes for fasteners according to the mounting template.

- Connection of a complete threaded fitting to the gas pipeline.

- Checking the amount of volume of the built-in tank. If there is a shortage, an additional tank is installed next to the boiler.

- Installation of a non-return valve in case of connecting a second tank.

- Flushing the line and removing air from it.

- Connection to cold water pipes of a stopcock and non-return valve.

- Installation of the filter at the entrance to the domestic hot water system.

- Installation of a gas meter, stabilizer and circuit breaker.

- Connection of electrical elements - cores in plug-in terminals, plug in the socket of the board.

- Cable fastening with clamps.

Commissioning of the device is carried out only by a specialist with a Protherm certificate.

User manual

A user manual is supplied with the unit. The document contains the basic rules for the operation of the boiler:

- If there is a smell of burning in the room, you can not turn on the light, smoke, use the phone. The device immediately turns off the network, and the boiler room is aired.

- There should be a place for servicing near the appliance. A clearance of 30 cm is needed above and below the structure. 10 cm remains on the side and 60 cm near the front.

- With a long departure, the valves for heating, domestic hot water and gas supply are shut off.

- Recommended coolant pressure is from 1 to 2 bar.

- Explosive and flammable substances, paint products should not be stored near the boiler.

- To select the heating mode, press MODE. To go to "Summer" - the same button twice, in the "Vacation" - three times.

- Water temperature parameters are set using the plus and minus keys.

- To set the temperature indicator of the heating main, you will need to press MODE, and then “plus” or “minus”.

Operation of the device is prohibited during defrosting of the system or leakage of coolant.

Major breakdowns

In case of device malfunctions, a code is displayed on the LCD display, by which an error is recognized. The algorithm for working with it is presented in the instructions. Other common equipment failures include:

- breakdown of pressure sensors, temperature, gas control valves;

- malfunction of the gas supply system or ionizing valve;

- chimney blocking - no air supply;

- stop when the voltage drops in the network;

- short circuits - sensors of the water supply circuit, housing, pressure switch;

- formation of air jams;

- problems with software - water is heated, but the circuit is not heated.

Error codes can be eliminated according to the manufacturer's recommendations. Defective parts will need repair.

Popular modifications

Chip equipment Proterm - "animal", "predatory" name of the series:

Chip equipment Proterm - "animal", "predatory" name of the series:

- Tiger - dual-circuit devices with an electronic unit.

- Leopard and Lynx - a double-circuit type for wall mounting with complete bithermic heat exchangers.

- Panther - a model with two circuits and a closed camera.

- Bear and grizzly bear - units with automatic adjustment.

- Cheetah - equipped with a built-in circulation pump.

- Scat - with a minimum level of harmful emissions.

- Bison and Beaver - outdoor options.

Only dual-circuit models have a built-in boiler.

Features of the Cheetah line

Gepard series is suitable for a private house or apartment, does not take up much space in the boiler room. Several devices are popular among users.

Gepard 11 MTV - model with an atmospheric burner, which is installed in a residential building up to 100 squares. Distinctive features:

- 11 liters of water per minute for the domestic hot water system;

- 5 liter expansion tank;

- Efficiency of about 90%;

- wall mounting method;

- LCD display with adjustable power;

- the presence of a pressure sensor and a self-diagnosis system.

The performance of the model is not enough for a coolant volume of more than 50 liters.

Gepard 23 MTV is a wall-mounted device with a closed camera. The features of the Proterm Cheetah boiler modification 23 MTV include:

- a power indicator of 23.3 kW, which is enough for a house of up to 200 squares;

- chimneyless type of unit;

- water heating for hot water supply by 38-60 degrees, for heating - 38-80 degrees;

- 220 V electrical connection

- the consumption of main gas 2.4 m3 / h, liquefied - 1.02 m3 / h;

- the optimal pressure in the hot water supply and the heating circuit is 3 bar.

Not suitable for hard water, as quickly clogged with sediment.

Gepard 11 MOV - a dual-circuit unit with a power of 9-11 kW wall type. Device specifics:

- open combustion chamber with auto ignition;

- Efficiency 90.3%;

- pressure in the circuit - 3 bar, in hot water supply - 10 bar;

- it is completed with an expansion capacity of 5 l;

- equipped with systems for monitoring gas pressure, flame attenuation, overheating and freezing of water.

It is allowed to connect an additional external temperature controller to the boiler.

Gepard 23 MOV - gas compact boiler manufacturer Protherm series Cheetah 23 MOV - wall type. It features an open combustion chamber, accelerated heating of the liquid. Equipment Specifics:

Gepard 23 MOV - gas compact boiler manufacturer Protherm series Cheetah 23 MOV - wall type. It features an open combustion chamber, accelerated heating of the liquid. Equipment Specifics:

- natural traction system;

- power equal to 23 kW;

- two heat exchangers - from copper (primary) and stainless steel (secondary);

- self-modulating burner;

- Efficiency from 90.3 to 93.2%.

If there are reconfiguration mechanisms, the Cheetah 23 boiler runs on liquefied gas.

Gas units Protherm Cheetah series are characterized by build quality and durability. They are suitable for wall mounting in the private sector or apartment in a high-rise building. When choosing equipment, it should be borne in mind that a two-year warranty is issued only when the boiler is installed by a specialist.