Bath and sauna are rooms in which it is necessary to create and maintain a special microclimate. The temperature in the steam room reaches 70-90 ° C. To reduce heat loss, a thermal insulation system is being thought out during the construction phase. From a wide range of building materials, experts recommend the use of foil insulation for a bath. It is resistant to high humidity and effectively reflects infrared radiation.

The need for thermal insulation of the bath

The steam room is good for health, it promotes skin rejuvenation, dilates blood vessels, and speeds up metabolism. When building a bath, builders take into account the special requirements for the design. It should warm up quickly and hold the heat for a long time. To fulfill these requirements, reflective thermal insulation for the bath is mounted. Without high-quality insulation, the steam room will not be able to function, or the cost of heating will be huge. Practical bath owners note the benefits of thermal insulation:

- extended bath life;

- The amount of time the temperature rises to a maximum decreases

- reduced consumption of firewood, coal or electricity for heating the sauna;

- basalt insulation increases the fire safety of the building.

Thermal insulation is installed inside or outside buildings. In the case of heat insulation of the steam room, the material for internal work is chosen. Several layers are installed in series, including steam and waterproofing. The use of insulation for baths and saunas with foil allows you to do with one material that performs all of the above functions.

Criteria for choosing a heater for a sauna

When choosing the optimal insulation for the bath should focus on the basic requirements for the material:

- coefficient of thermal conductivity;

- the presence of a reflective layer;

- moisture resistance;

- working temperature;

- thickness;

- flammability.

The specifics of saunas with high humidity and temperature require attention to the quality of the material. Complicated conditions adversely affect the insulation, reducing its life. Manufacturers take into account the requirements for thermal insulation of baths, create special series with the corresponding marking. An important factor is the absence of harmful emissions when heated. When buying a heater, it is worth reading the manufacturer's information.

In saunas with wood-burning stoves, the combustibility index of the material should be taken into account. Basalt or mineral wool does not support combustion, foamed polyethylene melts.

Characteristics of insulation with foil

The use of insulation for the bath on the walls inside with foil or metallized coating allows you to create the effect of a thermos. Heat transfer from heaters occurs due to infrared radiation. So that the energy does not leave the premises, a metallic screen is installed, reflecting it. It is advisable to insulate all sections of the structure: ceiling, walls, floor. A continuous coating will reduce heat and moisture loss.

Mounting the foil without a layer of insulation is impractical. This is a thin material that is easily damaged during installation. In addition, aluminum has a high thermal conductivity, which is unacceptable in the bath and sauna. Proper installation and a layer of thermal insulation material eliminate the problem.

The main characteristics of foil insulation:

- High ability to reflect infrared radiation of 90-97%.

- Low thermal conductivity due to the cellular or fibrous structure of the material.

- Vapor tightness - a coating of an aluminum layer does not allow vapor molecules to pass through; installation of additional protective films is not required.

- Waterproofing - the material does not absorb moisture.

- Resistance to high temperature - heaters are designed for operating temperature in a wide range, the upper limit is 150-300 ° C.

- Accessibility of installation - most insulation materials are available in the form of rolls and mats, which allows you to install them yourself.

In addition to heat-insulating qualities, the sauna heater with foil has vapor barrier and sound-absorbing properties.

Foil material selection

Thermal insulation with foil for a bath differs in technical characteristics and properties. The choice of insulation is influenced by the structural features of the room, fire safety requirements, and the complexity of installation. For stone and concrete buildings, mineral wool is recommended. It is a reliable material of considerable thickness, which will provide an appropriate level of insulation.

A building made of timber or logs does not require much effort to maintain temperature. Wood itself is a good heat insulator. In this case, penofol or kraft foil is enough. A review of popular options will help you decide which material is best to use.

Roll heat insulator

The insulation in the form of a rolled web can be from 20 to 150 m long. The thickness of the material varies from 2 to 40 mm. The basis is foamed polyethylene or propylene. Due to the fine spraying of aluminum, the material reflects thermal radiation. Penofol is popular in the domestic market. The material is available with single or double-sided foil with a self-adhesive base.

Roll foil without foundation is laid on the surface of the walls after the insulation. Strips with a width of 1-1.5 m are overlapped. The formed surface is highly resistant to temperature (up to 650 ° C), moisture and steam.

Basalt wool with a foil layer

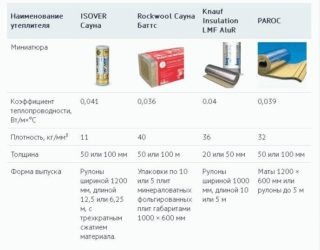

Mineral or basalt wool is a universal fibrous insulation. It is resistant to fire and moisture, provides excellent thermal insulation of the room. Foiling of the outer layer reduces heat loss, creates a vapor barrier. Among the assortment of leading manufacturers Isover, Park and Rockwool, you can choose special materials with foil for insulation of the bath.

- For anti-condensation insulation, ROCKWOOL ALU is recommended. The material is supplied in mats. Its fibers are perpendicular to the surface. During operation, the strength and elasticity of the wool is not lost. The Sauna Butts series is designed for warming saunas and baths. Mineral wool plates 50 and 100 mm thick serve as heat and vapor barrier. The material is intended for indoor installation.

- Roll insulation Isover Sauna quickly installs on walls and floors, provides reliable insulation. It is safe for health, has no harmful secretions when heated and wet. The material allows you to save on the installation of membranes and films.

- The popular insulation of the brand Paroc is offered in the form of lamellar and piercing mats. They are convenient to operate, quickly mounted on an insulated surface. The aluminum layer is reflective. Basalt wool does not change its thickness during operation.

The quality of thermal insulation depends on the thickness of the selected mineral wool. The best option is 5-10 cm. Basalt wool is fireproof, does not rot from moisture, and has a long service life.

Kraft foil

The use of a heater with a layer of aluminum allows you to achieve maximum preservation of infrared radiation inside the steam room. The multilayer structure consists of kraft paper and foil, in some cases polyethylene is added to reinforce the material. Common types:

The use of a heater with a layer of aluminum allows you to achieve maximum preservation of infrared radiation inside the steam room. The multilayer structure consists of kraft paper and foil, in some cases polyethylene is added to reinforce the material. Common types:

- folgizolone or foiled glassine - an elastic material based on cardboard with a corrugated coating of aluminum;

- foil-fabric - fiberglass insulation duplicated by foil, reflects up to 97% of radiation, withstands temperatures of about 200 ° C;

- isolar - foil for a bath 50 and 100 microns thick with the addition of a plastic film, resistant to fire, temperature up to 300 ° C.

Among the varieties of insulation it is worth noting a novelty - PIR plates from Technonikol with a foil lining. The range of products for insulation of the bath creates a reliable barrier between the cold from the street and the hot humid air of the steam room. Plates are lightweight, low water absorption, resistant to deformation

Installation of insulation with foil

When installing a foil insulation for a sauna, the following rules must be observed:

- A layer with aluminum foil is directed inside the room.

- When installing the material on the ceiling, descent to the walls is made, from vertical surfaces to the floor. This is necessary to drain the condensate.

- In the steam room ventilation is necessary.

- A gap of at least 30 mm is left between the foil layer and the bath trim.

The sequence of installation work depends on the type of insulation. Roll the penofol roll, cut into canvases of the desired length and fasten to the walls with a stapler. Under basalt cotton wool, it is necessary to make a frame according to the thickness of the material. Mats are stacked in a finished crate. Joints of canvases are glued with metallic tape. On top of the insulating layer, 30 × 50 mm slats are packed. The crate will provide the necessary ventilation gap between the insulation and the casing of the steam room.

You can insulate the bath and sauna with your own hands. Popular materials with foil will provide the necessary level of protection against heat loss, will save on heating.