Insulation of flat roofs is carried out according to canons, significantly different from the thermal insulation of pitched roofs. In flat versions there are no parts of the rafter system, so installation must be carried out according to a different principle. Before work, it is necessary to study the quality requirements of thermal insulation materials and determine the type of roof device.

Material Requirements for Thermal Insulation

It is advisable to carry out insulation of a flat roof using materials with reduced thermal conductivity. When choosing any insulation for a roof, it is necessary to take into account that the period of its operation will depend on many reasons, including temperature and humidity conditions, humidification of the diffuse and capillary type, and mechanical influences. A good heat insulator should maintain its properties for a long time, remain moisture resistant and environmentally friendly, keep resistance to chemical and biological components, and also comply with fire and sanitary standards.

A good insulation for a flat roof should be extremely durable, have the right level of resistance to tearing and compressing, not to delaminate and not to change the structure. Before purchasing materials, you should first of all get acquainted with the accompanying documentation for them and buy thermal insulation, the quality of which is confirmed by all necessary certificates.

Roofing Options

A flat roof can be mounted in two versions: operational and non-operational. Each of them has its own characteristic features regarding installation.

Operational

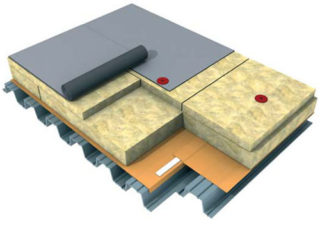

Installation of roof insulation of an operational type is carried out taking into account the fact that the roof will be used daily throughout the year, for example, as a terrace. Such a roof can be inverse or classic, the difference between them is the location of the roof insulation layer. In the first case, it will be located under the waterproofing layer, in the second - above it.

When installing the operational option, a special screed or reinforced concrete floor is laid under the waterproofing. This procedure is carried out so that the roof can withstand large loads unevenly distributed over its surface. The construction of an operational roof will be more expensive.

Non operational

A non-operational roof does not require additional maintenance, since it is used only for its intended purpose as a roof. It is not designed for loads in addition to snow, therefore, it does not need a rigid base under the waterproofing layer. The cost of this option will be lower, but the service life, wear resistance, durability and strength are less compared to the operational roof.

Varieties of thermal insulation

A flat roof device with any insulation can be single-layer or consist of two layers. The technology and installation methods for both options coincide in basic parameters, but also have some differences.

Single layer

Such a scheme is widely used during repair or construction from scratch of garages, warehouses or industrial buildings.Using a single-layer technology, a heater is installed for a soft roof under the screed, as well as options for other purposes. The insulation layer should be made of a material of uniform density. If the roof is to be operated, it is additionally covered with a concrete screed.

Double layer

For new buildings, a two-layer scheme is most often used when installing a thermal insulation system. It consists of two levels: lower and upper. The material used below is considered the main one and should have a thickness of 70-170 mm in combination with the ultimate thermal resistance. Thanks to the top layer, the load uniformly transfers to a flat system. Its material is noticeably thinner than the bottom - the thickness is not more than 30-50 mm. Thanks to this redistribution, the mass of the insulation and the entire system is noticeably reduced.

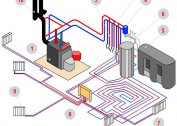

Vapor barrier value

Areas that are actively in contact with cold and warm air from inside the building must be protected from steam, as they are designed to separate cold and warm areas. Due to excessive wetting of the internal parts of the roofing material, the structure may begin to decay, mold mass, fungi and corrosion of metal elements will form in it.

To prevent steam from entering the thermal insulation layer and the accumulation of water inside the material and structures, a vapor barrier or a vapor barrier is used. It is a variety of films and materials that protect the thermal insulation and roof structure.

Materials for insulation of a flat roof

Insulation for hard or soft roofs can be different. They use materials that differ from each other in terms of quality, installation options and price.

Expanded clay

Expanded clay is considered one of the cheapest and most affordable options, like polystyrene foam or expanded polystyrene. With its help, it is not so easy to level the surface and make a smooth slope, as well as to achieve a uniform screed thickness for the entire roof plane. Working with such material can increase construction costs and its duration.

Perlite sand

Perlite sand is also an affordable option for insulation, it is quite a budget material. He is not able to compete with modern polymer parts and fiber-based insulation. Using sand is also not easy to level the roof surface; in addition, he will need additional protection from external influences.

Mineral wool

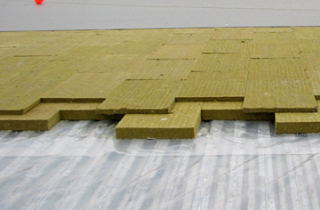

Mineral wool is often used to insulate the roof from the outside. Since it is not strong enough, an additional screed is used to strengthen it. Due to the prefabricated or wet screed, the load will be distributed evenly, the roof surface will become durable and will have the necessary rigidity. Experts advise choosing the most durable slabs made from basalt rocks.

Basalt fiber

Insulating the roof with rigid basalt fiber boards is for those who want to maximize the life of the roof. Plates do not cause difficulties during installation, they are characterized by optimal heat-insulating properties and have an increased level of fire safety. Their main disadvantage is increased hygroscopicity. If the layer is damaged and cracks form in it, moisture will begin to penetrate. In the process of getting wet, the basalt insulation for the roof will lose its basic properties.

Foam glass

Foam glass is resistant to high temperatures, high strength, resistance to ultraviolet rays. It is not susceptible to corrosion, retains its shape for a long time due to the reduced coefficient of expansion due to high temperatures, and also has the longest service life. The main disadvantage of foam glass is the high price.

The nuances of fixing the insulation on a flat roof

Regardless of the choice of material, you need to firmly fix it on the base. To do this, you can apply one of two available methods:

- Sticking on bitumen. This is a rather expensive and complicated process, it is worth choosing if there is a concrete base, so as not to purchase expensive dowels in addition.

- Mechanical method based on dowels. These elements are equipped with wide hats, with which the fasteners do not pass through the waterproofing surface and do not affect the tightness of the roof.

According to the rules of construction, the waterproofing carpet is attached to the insulation in the same way with which it was fixed on the base. If the insulation consists of two layers, the plates are laid “apart”, the joints of the lower tiles should cover the upper ones. Compliance with this rule makes it possible to avoid the formation of “cold bridges”. At least two dowels are used to secure all plates.

If the elements are fixed mechanically, polymer bitumen materials are recommended as steam insulation. Due to their elasticity, the holes will tighten evenly.