Fireplace doors are a special device that performs a number of important and versatile functions. Its main task is to ensure fire safety during operation of the outbreak. In addition, the part is part of the interior of the room, having a significant impact on the formation of its style. There is a huge range of similar products. To choose the doors for the fireplace, you should familiarize yourself with their types, features, pluses and minuses of a particular solution.

Types of fireplace inserts

The basis of any fireplace is a firebox - a compartment inside the portal in which fuel is burned.

The standard device of the furnace on wood, coal and peat ::

- Cast-iron grate (grate). Firewood is laid on them, air is supplied, ash and ash wake up.

- Ash box. For collection and removal of waste material.

- Lining. Protects the back of the device from overheating, reflects the generated heat into the room.

- Deflector. It delays combustion products from direct retraction into the chimney, contributes to an increase in the efficiency of the source.

- Exhaust pipe. Removes smoke and soot from the stove.

- Air regulator. Increases or decreases the amount of oxygen to the grate.

- Afterburning system. Converts untreated fuel particles and gases released by it into thermal energy.

- Glass cleaning mechanism. It supplies air to the door, preventing soot from settling on it.

According to the design of the furnace there are open and closed.

In open structures, firewood is fenced only with a decorative lattice. It is beautiful, exotic, allows you to admire the open flame. The downside is that there is a possibility of sparks falling on the floor, the efficiency of an open fireplace is extremely low, since almost all the heat in the literal sense of the word goes into the pipe.

Closed type constructions are more economical. The furnace is hermetically sealed by a door, smoke collectors and fuel afterburning systems are installed inside.

Advantages and disadvantages

Each type of fireplace inserts has its own advantages and disadvantages. They need to be considered when choosing a product when buying or preparing for the manufacture of their own hands.

Open type products have such advantages:

- presentable appearance;

- the smell of wood and fire smoke;

- affordable price;

- ease of manufacture in the home;

- ease of maintenance.

Cons of this design:

- risk of fire;

- danger of carbon monoxide poisoning;

- high fuel consumption with low heat transfer.

Hearths with open fire chambers are rather decorative components that serve to create an appropriate interior.

Closed-chamber fireplaces have the following advantages:

- Fire safety;

- profitability;

- good heat performance;

- the presence of additional devices that increase the efficiency of the product;

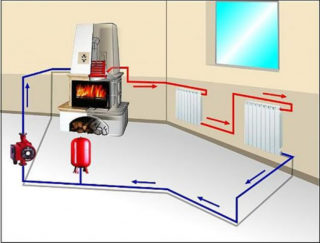

- the possibility of supplying circuits for heating water.

The disadvantages of the focus:

- higher price;

- difficulty in cleaning and maintenance.

Fireplace structures can be used to heat one room or a small building.

Varieties of fireplace doors

The trading network presents a wide selection of fireplaces equipped with doors made of various materials. Each of them has its own characteristics, weaknesses and strengths.

The most common products are:

- Glass. Refractory material is able to withstand temperatures up to 1000 degrees, which is quite enough when using firewood as fuel.The leaf can be transparent, colored, solid or with metal inserts. A fireplace with a glass door creates an atmosphere of comfort and coziness thanks to the visible flames.

- Cast iron. This alloy is the most heat resistant of all household appliances used in the manufacture. The metal is resistant to corrosion, it is easy to clean from dirt. In the process of heating and cooling, cast iron retains its shape, not succumbing to deformation. To improve aesthetic characteristics, doors are coated with heat-resistant paint or finished with forged parts.

- Steel. The production uses a flame-retardant alloy that is immune to high temperatures. Steel doors are affordable, practical and reliable, but inferior to glass counterparts in aesthetic terms.

- Ceramic. Such designs look great and are highly efficient. The room is heated by heat and infrared radiation generated by the firebox and door.

- Steel

- Cast iron

- Glass

The shape of the fireplace door with glass can be hinged (1 or 2 leaves), sliding, removable and lifting. The combined products created from metal and transparent details are popular.

Choosing the size and design of the fireplace door

When choosing a fireplace door, you should consider all the little things and nuances.

It is recommended to pay attention to the following criteria:

- Aesthetics. If the hearth is purchased for the interior, preference should be given to transparent sashes through which fire will be visible.

- Contingent living in the house. If it has children and animals, you will need a door with an additional protective shield that reduces the temperature to 40-50 degrees.

- The size. The larger it is, the better the heat transfer and the more beautiful the appearance of burning firewood. At the same time, the material must be heat-resistant enough to maintain its size and shape under strong heating.

- Type of fuel. If you plan to use coke and coal, cast iron is recommended. For firewood and briquettes, glass and ceramics are suitable.

- Way of opening. The most effective are double-wing designs. They are distinguished by reliability and ease of use.

- Functionality. It is advisable and promising to take products equipped with afterburning and heating systems. This will make it possible to achieve good savings on heating and the preparation of hot water for domestic purposes.

When buying finished products or parts for their manufacture, you need to prioritize in favor of quality. A fireplace is a fire hazardous construction; the slightest deviation from technology can cause a tragedy.

Do it yourself door

The manufacture of doors may be the stage of construction of a new fireplace or part of a modification of the product assembled earlier. The procedure is complicated, but with the skills to handle household tools feasible to the home master.

Work begins with the preparation of the project. The diagram shows the place of installation of the frame, the method of attaching it to the furnace, camouflage on the portal, the order of attachment of accessories. Based on the calculations, materials are acquired and tools are prepared. For the manufacture of frames and sashes, it is better to use refractory steel. It is almost impossible to process cast iron at home, and aluminum is subject to corrosion and is difficult to weld.

To work, you will need:

- welding machine, electric drill, grinder;

- screwdrivers;

- riveter;

- tape measure, square, miter box;

- refractory steel;

- heat resistant glass;

- gasket non-combustible cord;

- heat-resistant adhesive.

In the future, you need to perform the following actions:

- Saw workpieces of metal and glass (ceramics).

- Secure steel parts with clamps and weld them together.

- Drill holes in the wings and frame and rivet fittings.

- Glue transparent fragments to the doors or insert them into the holders.

- Cover the frame with a refractory insulating cord.

- Insert the frame with the leaves in the firebox and fix it there by welding or bolts.

- Finish facing the metal and the updated portal.

It remains to conduct a test firebox to make sure that the design is operational and safe.