The cost of gas and electricity rises, and it is impossible to save on heat in the Russian climate. An alternative is heating with wood or wood waste. In addition, there are settlements where heating with a wood stove is the only possible option. But old-fashioned stoves are the last century. To ensure that the heat supply is economical and safe, it is important to choose and install a modern wood-fired boiler correctly.

Device and principle of operation

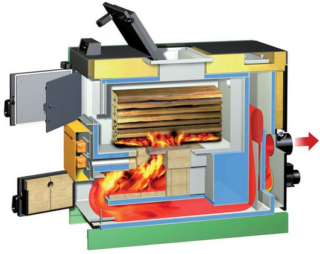

Each heating boiler must have a combustion chamber, a heat exchange element, an ash pan and a chimney. The simplest apparatus is an oven equipped with a water tank. It is heated by burning wood and sent to the heating circuit.

The heating equipment operates as follows:

- Firewood is loaded into the combustion chamber, where they burn and give off heat to the heat exchanger.

- Pipes are connected to the heat exchange device, the purpose of which is to supply hot water to the common heating system. It is equipped with batteries, expansion tank and nozzles. In addition to heating the liquid, the unit heats the room where it is installed.

- When burning firewood, smoke appears, discharged through the chimney to the street. In this case, soot settles on the walls. A significant amount of it in the chimney leads to a decrease in draft and an increased risk of fire.

- The supply of cold and the removal of hot water from the heat exchange element is carried out using pipes. Automatic devices are installed on the new generation devices, which greatly simplify the maintenance of boilers for a wood-burning house.

The chimneys are cleaned with special openings called closed shutters. For this purpose brushes and ruffs are used. Also, you can add a composition to the firewood, when burning, cleans the chimney from the inside.

Advantages and disadvantages

Modern boilers for heating on wood for a home are characterized by increased efficiency - about 80 percent. In addition, modern units have many other advantages:

- for installation it is not required to obtain the permission of gas workers and firefighters, as well as notify neighbors;

- there are modifications that are adapted to work not only on wood, but also on pellets, coal;

- often devices are equipped with cooking hobs for cooking or heating food;

- combined devices can not only heat the home, but also warm the water.

The most important advantages are independence from electricity and profitability. The cost of firewood is approximately half that of natural gas. Electric heating is even more expensive than gas.

Firewood units also have their drawbacks. In cheap boilers, you have to add fuel every 2–4 hours. In addition to the boiler room, a place is required where the firewood will be stored.

The performance of wood boilers is influenced by what type and quality of fuel. If only wood heating is provided, peat briquettes and coal are not allowed. Also, it is not allowed to use insufficiently dry firewood - when burning they emit a lot of steam and soot.

Varieties of wood-fired boilers

Solid fuel devices are divided by type of combustion. For simple boilers, the efficiency is not too large, and fuel costs are significant. The operation of modern devices is based on the principle of long burning. It implies restricting the access of oxygen during the combustion of wood.In fact, firewood smolders rather than burns, while generating more heat. It is possible to adjust the power output. The peculiarity is that one batch of fuel lasts an average of 20-22 hours, the time depends on the size of the combustion chamber.

Solid fuel devices are divided by type of combustion. For simple boilers, the efficiency is not too large, and fuel costs are significant. The operation of modern devices is based on the principle of long burning. It implies restricting the access of oxygen during the combustion of wood.In fact, firewood smolders rather than burns, while generating more heat. It is possible to adjust the power output. The peculiarity is that one batch of fuel lasts an average of 20-22 hours, the time depends on the size of the combustion chamber.

Models using the pyrolysis method are also classified as continuous burning equipment. Their difference lies in the separation of fuel into solid residue and pyrolysis gas, which accumulates in the chamber adjacent to the furnace. Due to this, the efficiency increases to 85 percent, and the volume of ash decreases to 7-15 percent. Gas-generating boilers have only one drawback - chamber drying fuel is required, otherwise the operation of the unit in normal mode will be impossible.

Home boilers are also divided according to the number of circuits that heat the water. They are single-circuit and double-circuit.

The first type is intended only for space heating. The second is also used for hot water supply. For this, two coils are installed in the furnace compartment.

Single-circuit boilers can also be used to provide residents of the house with hot water. To do this, indirect heaters are connected to them. But there is a minus - the need to purchase additional equipment.

Criterias of choice

When choosing a boiler, it is worth considering the following indicators:

- Heated area. Sample efficiency calculations are performed according to the formula 1 kW = 10 sq.m. For example, in the central part of Russia, for heating a house with an area of 150 square meters, a device with a capacity of 15 kW is required. For colder regions, a more powerful aggregate is needed. To heat a similar house in Siberia, it is worth taking a device with a capacity of 30 percent more. When connecting a second water circuit for domestic hot water, add another 15–20 percent to the final value.

- Material. Cast iron equipment can stand for 35 years, it has the best thermal and technical indicators. But such units are unstable to mechanical damage and weigh a lot. Steel devices are cheaper, they are not afraid of shock, but their life is on average 10-15 years shorter.

- Type of loading firewood. More often, devices are made in which lateral fuel intake is provided. But there are also top-loading models. A similar design is used in gas boiler. The main advantage of the solution is the possibility of pre-drying firewood, which increases the heating efficiency.

- The ratio of the volume of the combustion chamber and the power indicators of the boiler - how many times during the day it is necessary to load fuel. For steel apparatuses, this value is on average 1.5–2.5 l / kW versus 1.1–1.4 l / kW for cast iron ones.

- Burn protection. An important characteristic, especially with open access to the boiler room. This is achieved due to the thermal insulation of the handles of the combustion chamber, other highly heated elements that protect the cases and grilles.

- Additional functionality - automatic sensors, built-in storage boiler, remote control system. All this makes the operation of the heater more convenient. But for some options it is necessary to connect to an electric power source, which deprives the unit of autonomy.

In addition to technical indicators, you will need to determine the brand of the wood boiler and the cost. A good option in terms of price and functionality will be one of the modifications of the Kupper boiler. Their advantage is also compact, which will allow you to place the device on a small area.

Installation Features

A wood-fired heating boiler can be installed anywhere if it meets the technological and fire regulations. A technical room with ceilings above 2.2 m and an area of 8-12 sq.m. is suitable for a boiler room.Supply and exhaust ventilation should be installed, light should be installed. Only non-combustible materials are suitable for interior decoration. You can mount the boiler in the basement, but with the condition that it is dry.

When installing, you also need to consider:

- The wood boiler is mounted on a solid foundation. When connecting the device from cast iron, you will need to build a concrete base.

- To prevent accidental ignition during fuel loading, the base of the tree in the direction of opening the furnace door is closed with a sheet of metal or asbestos cement.

- Installation of the unit is carried out in a place where it will be convenient to service. All items must be freely available.

- Firewood should be stored in an adjacent room.

- Installation of a chimney pipe is carried out following the fire safety requirements during installation. All parts that are heated and pass through the floor slabs and the roof are insulated. A spark arrester is placed on the outlet of the chimney.

If the unit is designed to be connected to an electrical network, use a voltage stabilizer and an uninterruptible power supply. Automation is connected from the shield by means of circuit breakers and RCDs. In general, the installation is not complicated, it is quite possible to do it yourself.

Rules for the operation of wood boilers

In the process of using a wood boiler for heating a private house, observe the following precautions:

- Do not leave operating equipment unattended for a long time to avoid overheating;

- when working with the furnace, do not forget to wear gloves that protect against burns;

- Keep children away from the boiler.

It is important to store firewood no closer than a meter from the firebox, but rather in a specially equipped room.

For the efficient operation of the wood heater, it is necessary to constantly consume significant batches of fuel, store it in low humidity. However, you can be sure that the house will be warm even if the supply of electricity or gas is interrupted.