When choosing a warm floor as the main or additional source of heating, you must carefully consider the method of installation. It will be necessary to take into account not only the option of laying the contour, the location of the collector, the finish material. It is important to provide high-quality thermal insulation of the base and reliable fixation of the pipes. The efficiency of the heating system as a whole depends on the quality of the heat-insulating layer. Therefore, ready-made mats for a warm floor will be the optimal solution to several issues - warming the base, preserving thermal energy and attaching pipes with a coolant.

Purpose of mats

Water floor heating can be an addition to the main radiator heating or completely replace it. The essence of the work lies in the fact that pipes with a coolant are laid in the floor structure - they are poured with a screed, or mounted by the “dry” method. Hot water comes from the collector or from the central network and is carried along the contours from which thermal energy enters the room. This ensures uniform heating.

The effectiveness of the system directly depends on minimizing heat loss. Heat should be distributed exclusively up to the side of the room, and not partially go down through the base. If we neglect the thermal insulation, the foundation will be heated, and the room will remain cold.

Another issue that arises when laying pipes is protection against mechanical stress and load, as well as their reliable fixation.

Pipes take on a rather high load from the coolant, screed, clean floor construction, furniture, equipment and people. Therefore, the minimum density of the material used for the manufacture of mats is at least 35 kg / m3.

Advantages and disadvantages of use

With proper installation, the substrate under the warm floor, in addition to the thermal insulation, performs a soundproofing function. This is important because the water system can make distinctive sounds. If you choose pipes with a perfectly smooth inner surface, the system will be virtually silent. Also, the material must have waterproofing properties.

The advantages of mats for warm water floors include:

- High performance and durability (up to 50 years).

- Heat and sound insulating properties.

- Easy installation regardless of the type of screed - wet, semi-dry or dry.

- Preservation of geometric parameters throughout the entire life cycle.

- The presence of a lock connection for a snug fit plates.

- The presence of markings to facilitate the installation of circuits.

- Resistance to corrosion and microorganisms.

- Moisture resistance.

- Heat resistance - mats can be operated under the influence of too high or low temperatures.

- When heated, the material does not emit toxins and an unpleasant odor.

For the manufacture of mats use expanded polystyrene. In its raw form, it is a combustible and flammable material that releases toxins during combustion. However, to make the insulation safe, in the manufacture of mats, flame retardants are introduced into the composition of the polystyrene foam, which make it self-extinguishing.

Varieties of mats

When installing the underfloor heating system, several types of mats can be used, which differ in the material of manufacture, appearance, way of laying, and functionality.Conventionally, they are divided into two large groups - roll and sheet.

Roll

Experts recommend purchasing roll material if the system is in addition to the main heating and is placed above the non-residential premises. The material for the manufacture of such mats is penofol or foamed polyethylene with a front foil layer. Thermal energy is reflected from the foil and sent up.

A feature of such substrates is a smooth surface to which the pipes are fixed. To do this, you can use special plastic holders or fix the contours with plastic clips to the reinforcing mesh, which is laid on top of the substrate to strengthen the screed. This type of insulation is the cheapest. Thickness varies from 2 to 10 mm. When laying it, special attention is paid to joints - they are glued with foil tape.

Another variety is expanded polystyrene mats with an additional layer of foil and polymer film. Thanks to the marking, the laying of pipes on such a heater is easier and faster. The circuit is also fixed on top of the reinforcing mesh with plastic clamps.

Leafy

For the manufacture of sheet substrates using different materials. Products differ in thickness. Polyethylene foam substrates can have a thickness of 1 - 12 mm. This kind of insulation is not recommended due to susceptibility to deformation. Crosslinked polyethylene foam has good performance. The thickness of such a sheet of insulation varies in the range of 2 - 20 mm. The material is resilient and stiff.

With water heated floors, a polystyrene sheet substrate is often used, the thickness of which can be 5-200 mm. The main plus is the incombustibility of the material and moisture resistance.

PPP is of three types:

- press;

- no-stress;

- extrusion.

PPS extrusion substrate suitable for all types of underfloor heating. The types of substrates that are used as a heat insulator include PPS sheets with a smooth surface. Their thickness is at least 5 cm. The main advantages: durability, strength, resistance to mechanical stress, the ability to retain thermal energy. This is an excellent option for warming the ceiling of the first floor over an unheated room.

It should be noted that any polystyrene foam is afraid of exposure to chemicals that are also contained in the screed. Therefore, before pouring the solution, the PPS plates are closed with an airtight film.

What materials do heat insulators produce

For the manufacture of heat-insulating substrates, synthetic and natural materials are used. However, in tandem with a warm floor, extruded polystyrene foam is best manifested. It is an excellent insulation and has many other advantages.

EPP has low vapor permeability - water vapor does not pass through the material - and also it does not absorb moisture and always remains dry. Condensation does not form on its surface.

Due to the low thermal conductivity, the room retains heat for a long time. Styrofoam also has soundproofing properties. Rodents and bacteria are indifferent to it. This is the best option for a water-heated floor.

Substrates are also made from natural raw materials - jute, felt and cork. But they are laid on top, under the final coating.

- Felt

- Jute

- Bung

How to choose mats

When choosing mats, various factors are taken into account: requirements for waterproofing, material resistance to static and dynamic loads, section of the circuit, operating conditions in the room where the heating system will be mounted.

Roll substrates do not have very high waterproofing properties, so they are not recommended to be laid on the ceiling of the basement. Also, roll materials in apartments are not desirable. Although it is most likely that it will not be possible to mount a water floor in a multi-storey building because of the difficulties in obtaining permission.But if this succeeds, it is better to refuse the roll material - in case of leakage it will not help.

Excellent waterproofing properties are characteristic for sheet mats and foil polystyrene boards. They also have a low coefficient of thermal conductivity and maximally retain heat in the house.

When choosing a substrate, its ability to withstand loads is taken into account. Polystyrene mounting mats with relief, flat varieties and foil materials are best proven - they are all characterized by high density. These insulators will ensure efficient operation of the system, which can become the main source of heat.

It is important to choose the correct thickness of the mat - take into account the height of the room, the thickness of the screed and the finishing material. If an insulating layer is located beneath it, the product can perform mainly the mounting function.

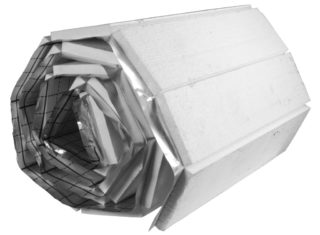

Plates with "bosses"

Separately, it is worth noting the convenience of working with mounting mats equipped with special plastic protrusions - bosses. Their shape can be different (circle, square, polygon), but this does not affect the functionality of the product. The bosses are arranged in rows at a certain distance from each other and allow you to securely fix the pipes without the use of additional fasteners. In this case, the optimum distance between the contours is observed, which can be laid according to any scheme, for example, with a “snail” or a “snake”.

During the pouring of the mortar, the pipes remain in the set position and do not move. One of the advantages of using such substrates is the speed of laying the heating system. Installation of the mats themselves also occurs quite quickly, since each plate is equipped with a locking system that ensures a tight fit of the products to each other without the formation of gaps.

Such plates are universal - they can be used for fastening pipes of any section and from any material, and also can be used in any floor construction. The thickness of the plates varies from 1 to 3.5 cm. The protrusions rise by 2 cm.

The plate is made of polystyrene foam and has high heat and sound insulation properties. Some boards have a film or waterproofing coating.

Backing

Regardless of the insulation chosen, laying the substrate under the underfloor heating floor is done through a waterproofing layer. The most reliable type is coating, since a monolithic coating will reliably protect against leaks and retain moisture in any volume. Dense polyethylene can be used. It is lapped, the joints are glued with waterproof tape. The edges of the film lead to the walls. Then, along the perimeter of the room, a damper tape is fixed.

Using a locking system fasten mounting mats laid on top of the waterproofing. If a roll or sheet substrate with foil is used, the joints are carefully glued with foil tape to obtain an airtight coating.

Pipes made of cross-linked polyethylene are laid between the bosses - this is the most convenient and kind of pipeline. Unwind the coil, press on the pipe with your foot so that it takes the desired position. Some mats come with heat-reflecting metal plates with a groove for the pipe.

After laying, the pipes are connected to the collector and water is released to check the operation of the system. Then pour the solution. Underfloor heating at full power can only be started after the screed has completely dried.