Modern technology allows you to turn any home into a cozy and comfortable place to live. Provided that the thermal insulation material is correctly selected, this is not difficult to do. At the same time, insulation allows you to save on heating. The estimated thermal insulation thickness depends on the climatic conditions in the area and a number of other factors.

Types and types of insulation

The following heat-shielding materials are traditionally used to warm the walls of residential buildings:

- Styrofoam;

- material under the brand name "Penoplex";

- mineral wool or its ecological analogue;

- polyurethane foam in liquid or solid form;

- plaster and similar finishing compounds.

The market of modern building materials is saturated with a large number of varieties of insulation structures. Some of them are suitable exclusively for wooden structures, while others allow you to get the desired effect only when laying under concrete.

The most popular insulation for walls is basalt mineral wool. The features of this material include:

- attractive thermal insulation characteristics;

- good sound insulation;

- fire protection;

- high strength indicators.

The disadvantages of cotton mats are high hygroscopicity, which forces it to be protected with a layer of plastic film. Glass wool is included in this category, guaranteeing approximately the same performance, but at a lower price. Its disadvantage is the harmfulness of glass dust to human health and the need to take measures to protect the skin and respiratory system.

Styrofoam plates are also a good base for wall insulation (styrene and extruded polystyrene foam belong to the modifications of this material). All of them are distinguished by good thermal insulation properties, providing at the same time a good level of sound insulation. Their disadvantages include fragility and susceptibility to deformation.

Liquid polyurethane foam is mounted on the protected surface by spraying, and solid workpieces are fixed on the walls by means of special adhesive compounds. This type of insulation belongs to the category of modern and relatively expensive materials.

The parameters taken into account when choosing the type of heat insulator

Regardless of which material the user selects as the main, it is important to correctly determine the thickness of the insulation for the walls. Subject to complete certainty with the material used in the construction (brick, timber or concrete), the choice of thermal insulation depends on the location of the building on the map of the country's regions. For wooden houses being built on the same project in the Moscow Region and in the Khabarovsk Territory, for example, the thickness of the insulation for walls made of cotton will vary significantly.

To take into account the factors affecting the choice of thickness of the insulating material, you will need to familiarize yourself with the current standards (SNiP 23-02-2003 “Thermal protection of buildings”). Together with it, the Application is considered under the number 23-01-99 “Climatology”. The first regulatory document provides the value of the thermal conductivity parameter for building envelopes (R0). The second of them will be required to identify the duration of the heating season in a specific region of the country.

The concept under consideration also defines such important parameters as:

- physical thermal insulation properties of the materials used;

- load capacity of the protective layer (resistance to deformation);

- features of installation at a specific facility;

- noise protection (sound insulation quality).

For any heat insulator, the following rule applies: the smaller its thickness and corresponding weight, the more convenient it is during installation. But when this indicator reaches a certain minimum, the insulation loses its functional qualities. When choosing it, the fact of the influence of the thickness of the material on weight and other parameters is always taken into account.

Calculation of the thickness of the insulation for walls

To calculate the desired indicator, it will be necessary to take into account the thermal resistance or thermal conductivity of the walls of insulated buildings in the form of the sum of the corresponding parameters of all structural layers, including load-bearing, without exception. Based on this, the thickness of the thermal insulation depends on the characteristics of the material from which its walls are made. For brick and concrete structures, more insulation will be required, and for wood and foam block constructions - slightly less.

It is possible to calculate the exact value of this indicator only if the climate in the construction site is known, the thermal conductivity of the material and the features of the supporting structures. The thinner they are, the more insulation thickness is selected.

Brick walls

The calculation procedure for bricks and other materials is easiest to implement using online calculators, in large quantities, presented on the Internet. In the calculations carried out for brick buildings, the value of the thermal conductivity of the material (0.6-0.95 W / meter K) is substituted in the proposed form. In the next column, the region of the insulated building is indicated. Many settlement services include density as part of the controlled parameters, for brick materials it is 1550-1900 kg / meter cubic.

Based on foam blocks

Similar calculations are carried out for buildings built on the basis of lightweight foam blocks, widely used in private and industrial construction. To obtain the desired indicator, the same calculator is taken, in the columns of which the corresponding parameters are entered. In this case, their values will be represented by the following numbers:

- thermal conductivity - 0.14-0.38 Watt / m K;

- density - 400-1200 kg / cubic meter.

After entering these numbers in the appropriate windows and indicating the area, it is possible to obtain the required value for the insulation on foam blocks.

Frame house

For a frame house, mineral (basalt) wool is considered an ideal insulation. When using it, the calculation of the thickness of the protective layer is reduced to substituting in the calculator column the values of the thermal conductivity of common types of wood (0.14-0.17 W / m K) and a figure corresponding to its density. Permissible values of the latter are 450-600 kg / cubic meter. After indicating the area where the house is being built, the desired result is found.

Features of planning and design

Features of the planning of work on wall insulation consist in the fact that they are allowed to be carried out inside and outside the building. Bilateral or multilayer insulation is used only in exceptional cases (in regions with very harsh climates, for example). Another reason for choosing this option is the individual preferences of the owner of the house or structural design features.

The disadvantages of internal insulation include a decrease in the living space of the room, as well as the possibility of the formation of dew points on the border of two environments (between the wall and the insulation). Its positive aspects are:

- convenience of construction work;

- weather independent;

- the ability to leave the facades of the building unchanged.

With internal insulation, reliable protection against vapor fumes in the form of a layer of plastic film will be required. With the external arrangement of the insulation elements, the internal spaces remain unchanged and there is no need to use vapor barrier. At the same time, one cannot count on the old cladding of the building - it will have to be dismantled.

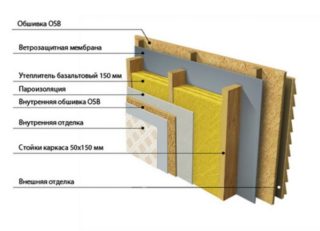

Wall Pie Composition

Before you insulate the wall of the house or the attic, you will need to correctly form the layers of the protective cake, which is a design of sequentially laid materials that provide the required level of insulation. The main components of such a pie are:

- frame of beams with a typical size of 15x15 cm;

- wooden crate of horizontal type or metal profile;

- mineral wool insulation layer (polystyrene foam);

- a special universal membrane that protects the structure from the wind and is a vapor barrier;

- vertically stuffed crate;

- internal wall cladding (drywall or lining);

- coating of finishing material.

For the manufacture of wooden elements of the pie you will need high-quality wood, dried in a natural way - in the open air under a canopy. Subject to all these conditions, the walls insulated with quality materials will serve the owners for many years.