How to optimize energy consumption in a heating system? To do this, it is necessary to control the level of water temperature in the pipes, and also to regulate the intensity of its passage through the batteries. The best way to do this in practice is to install valves for the heating system: needle, adjustment, for the radiator.

Functional purpose of heating valves

In autonomous systems, it is difficult to control the degree of heating of water in the pipes. In addition, in the rooms of a house it is often necessary to establish an individual temperature level. A simple balancing valve for the heating system will solve this problem.

All elements of the heating circuit, which are designed to regulate the volume of passage of the coolant, are collectively called shutoff valves. It can perform several functions - manual or automatic adjustment of the degree of water circulation, mixing hot and cold flows to optimize energy consumption. So, a valve for a heating battery with a thermal head can automatically limit the flow of water into the radiator.

Before choosing a valve for the heating system, you need to decide on its main operational characteristics:

- System mode - temperature and pressure parameters (optimal and critical);

- The degree of inertia of the device. By installing ball valves, you can quickly block the circulation of water in a specific area of the system. The needle ones are designed for smooth adjustment;

- Possibility of automatic work. Devices with automatic controls are of high cost. But their installation guarantees the normal operation of the entire heating system, and also frees the owner of the house or apartment from constant monitoring.

Given the wide variety of models and types of valves, in most cases it is difficult to choose a valve for a heating radiator or a simple ball valve. To solve this issue, you need to find out the types and design features of each heating control valve.

All types of thermostatic valves for heating are divided according to the installation method - horizontal and vertical. This must be considered when installing the device in the system.

Heating shut-off valves

This class is designed to adjust the passage of the coolant volume on a specific section of the system or the entire highway as a whole. The shut-off needle valve for heating is mounted on those sections of the pipeline where smooth adjustment of the fluid volume is needed - in the collectors of the warm floor, in the radiators. Spherical models are designed for operational liquid shutoff.

Ball valve

This type of valve appeared relatively recently - 20-30 years ago. Prior to this, a needle rod was used in the design, which did not provide operational shutoff of water.

The design of the ball valve is simple - a ball with a through hole is used as a locking element. When it is rotated, the axis of the hole shifts, as a result of which the coolant flow is partially or completely blocked. What is the difference between a needle valve for heating and a ball valve? In the latter, the diameter of the hole is always less than the cross section of the pipe. Therefore, in this section of the highway there is an increase in hydraulic resistance.

The installation of a ball valve for the heating system is necessary in the following nodes of the system:

- Radiator wiring - in the construction of bypasses;

- In key heating units, where the probability of failure is high;

- In front of each radiator.

It must be remembered that the principle of operation of the ball valve is not suitable for the control valve on the heating radiator. With its help it is impossible to regulate the volume of flow of the coolant with proper accuracy.

In the vast majority of cases, a handle is provided in the valve to rotate the ball. It moves 90 ° and should not touch walls or pipes.

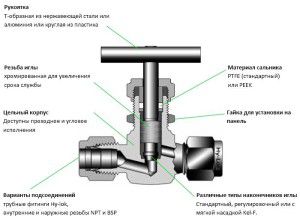

Needle valve

Each thermostatic heating valve has a needle rod needed to shut off the water in the pipes. It is perpendicular to the plane of the pipe, and at its end there is a saddle blocking the flow of coolant.

It can be installed not only as a valve for the heating battery, but also in those parts of the system where smooth adjustment of the water volume is required. The locking needle rod rotates on the internal thread in the valve body, reducing (increasing) the throughput of the tap channel. Due to the simple principle of operation, the needle valve in the heating battery can operate in several modes:

- Manual regulation

- Installation of servomechanisms connected to a temperature sensor will automatically change the amount of coolant entering the radiator or a specific heating section;

- An additional unit inside the valve for the heating radiator changes the position of the stem depending on the water temperature and user-set values.

In addition, needle valves for heating differ in the type of attachment - flanged or threaded. Also, when choosing, you should take into account the shape of the channel, which can be straight-through or angular. In autonomous heating systems of a private house, direct-flow models are most often used, since the pressure value in the pipes does not exceed 5 bar. Angle valves are mounted in highways where sharp pressure drops are possible and full sealing of the passage is required in case of a sharp surge in the pressure of a liquid or gas.

One of the characteristics of the needle valve for heating systems is the pitch of the internal thread. The level of adjustment of the coolant flow depends on this parameter.

Heating control valves

However, in addition to the above types of shutoff valves, valves are installed to control the heating. A needle shut-off design or with an adjustment plate is used as the main water shut-off mechanism. Depending on the functions performed, they are divided into two types:

- Automatic adjustment of the volume of water - most often they use the design of a needle valve for heating;

- Mixing 2 streams (with hot and cold water) to create the desired temperature. In autonomous heating, such valves are mounted on the collector of a water heated floor.

What is the difference between the control valve on the heating radiator and the usual shut-off valve? In its design there is an element that provides automatic operation.

Thermal Head Valves

The simplest design of a thermostatic heating valve includes a needle rod that is connected to a thermostatic control element. Depending on the temperature of the medium, it tends to expand or contract. This regulates the amount of coolant entering the radiator.

This device is mounted directly on the radiator inlet pipe. When choosing, you need to take into account that the balancing valves for the heating system can be of two types - with the manual setting of the boundary temperature of the coolant and with the ability to connect to external sensors. The latter are called servos and are designed for mounting on needle valves for radiators or mixing units.

Unlike a valve designed for heating, the servo is connected to an external temperature sensor or an electronic control unit. When you change any parameters of heating the air in the room or the temperature in the street, the valve rod moves. Thus, the flow of coolant in a specific section of the system is regulated.

An external thermometer connected to a thermostatic expansion valve must be mounted in a place where direct sunlight does not fall.

Is it possible to use this device complete with a valve for radiators in heating? Most often they are mounted on a 2 or 3-way valve for mixing hot and cold water. Installation in heating batteries is impractical, since the control valve on the radiator will perform the same functions, but its cost is much less.

When planning the installation of a new heating system or upgrading an old one, the cost of the control valves must be taken into account. It directly depends on the design and functionality of the device.

| Name | Note | price, rub. |

| Valtec Ball Valve ½ ” | Stainless steel | 160 |

| Needle Valve Fiv Oasi ½ ” | With the possibility of mounting a thermal head | 310 |

| Danfoss Thermal Head | Horizontal mounting | 816 |

| Kermi Servo | Installation via valve adapter | 703 |

Regardless of the choice of a valve for a heating system: needle, adjustment, for a radiator, you need to choose the right model with the appropriate mounting unit. After installing the device, the throughput of the system and its characteristics should not change.

The video material describes the nuances of installing a thermostatic valve on a radiator in a single-pipe heating system: