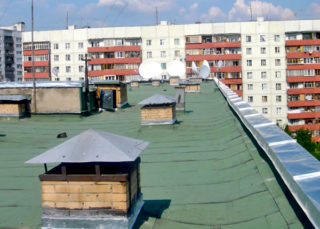

Today, several non-standard schemes for traditional heating methods are gaining popularity. One of these options is called roof boiler rooms. The method of installation and laying of all heating elements is difficult, but due to the large number of advantages, it is increasingly found in buildings of various enterprises and residential buildings.

The principle of operation of roof boiler rooms

The roof gas boiler room is an autonomous installation of a modular type. The equipment includes thermal and control modules, control automation and circulation pumps. The capacity of the roof boiler will directly depend on the number of thermal modules. All elements are connected together into one heating system.

The automatic boiler room system performs the following "work":

- local control over pressure and temperature parameters;

- alarm triggering when an autonomous boiler house illegally enters the building;

- automatic regulation of the temperature of the network water, taking into account the pressure drop in the return pipe;

- when there is gas, the gas supply to the boiler room is automatically turned off and the exhaust fan starts;

- inclusion of reserve network pumping equipment and a hot water supply pump;

In case of fire or severe gas contamination, the supply fan, which is responsible for supplying air to the system, automatically stops.

Advantages and disadvantages

The roof boiler room in an apartment building and various enterprises is increasingly being installed due to the advantages of the equipment:

- Profitability. The equipment is installed directly at the facility, people do not need to buy / rent additional territories for the construction of a boiler room. The most affordable type of fuel today is gas.

- Environmentally friendly, as the raw materials for heating are used clean and safe. With gas combustion, environmental damage is minimal.

- High efficiency. This type of autonomous heating systems works only on gas, and gas installations are considered the most effective. Efficiency of gas boiler houses reaches 95%.

- Full automation of the process. Thanks to the modern automated system that the boiler room is equipped with, uninterrupted operation without human intervention is guaranteed. Automation monitors the performance of all important parameters, even taking into account the weather outside the window. This approach provides additional fuel savings.

Despite the large number of advantages, there are disadvantages. The main ones are:

- Installations are allowed to be mounted on buildings no higher than 9 floors.

- The high cost of equipment, installation, connection.

- Pumps emit strong vibrational waves during operation, which can cause inconvenience to residents.

For residents of old houses, the installation of an autonomous heating system is not always possible. Not every structure is able to withstand such loads.

Varieties of boiler rooms

Technical and operational characteristics of the building, its type, condition and purpose determine the type of roof boiler house used:

- block-modular type;

- built-in type.

The first variety is used if an autonomous heating system needs to be installed in an already erected building. They are installed, as a rule, during the overhaul, where the built-in heating system needs modernization.

The project of an autonomous gas roof boiler is created taking into account the technical features of the structure. The finished system is transported to the facility and installed in a specific, predetermined location.

Before proceeding with the installation of the block-modular type of boiler rooms, it is important to properly prepare the roof covering for the upcoming loads:

- Specialists check the condition of the main elements of the structure, especially the bearing walls.

- A protective coating is applied to the installation site. As a rule, use a concrete pillow with a thickness of at least 20 cm.

- Be sure to carry out a set of measures to ensure safety and enhance sound insulation.

- Power plants after installation are connected to the heating network of the structure, creating a single system. Already directly on the spot, they regulate the operation mode, perform connection to the water supply and heating system.

Despite the full automation of the work, the boiler room is equipped with a special room for staff.

Building codes

The construction of roof boilers should be carried out taking into account all the requirements of SNiP to prevent accidents.

- It is impossible for the boiler room to exceed the dimensions of the multi-storey building itself.

- It is forbidden to mount equipment on the ceiling of living rooms.

- The equipment should be equipped with an automatic shutdown system in case of accidents.

- The equipment must not adjoin the walls of residential premises.

If the residents of the house decided to install an autonomous heating system, they should understand that all the waste will be divided between the property owners. In addition to the boiler room itself, you first need to take care of the design, delivery and installation. The average price ranges from 5-10 million rubles.