Stone wool is used for insulation of facades and interior walls of rooms. It is a durable building material that has a natural origin. Before use, the volcanic rock is processed accordingly, then form it from it, which are laid on the surface and fixed. Stone wool has many advantages over other similar materials, while its price is affordable.

The origin of stone wool

Volcanic rock - basalt - is thrown to the surface of the earth in the form of lava, then it solidifies and turns into stone. For some time it began to be used in construction. Due to the fact that basalt is easy to extract and there is a lot of it in nature, the cost of building materials based on it is available to everyone.

There are whole groups of volcanoes that give the largest amount of rock suitable for further processing. They are located in Kamchatka and the Kuril Islands. There are more sleeping volcanoes on earth, near which basalt layers have already formed - they are the main sources of rock.

Many islands are of volcanic origin and are fully formed from basalt rock, such as Hawaiian.

Stone wool insulation passes the following processing steps:

- Melting and grinding.

- Fiber production.

- Bonding with resin.

- Treatment with water repellent oils.

- Formation of formations of the desired shape.

The layers are made of different thickness and area. Sold in single-sided foil rolls or in the form of plates.

Characteristics of stone wool

The material retains heat due to motionless air bubbles. The more of them, the stronger the beneficial properties. The characteristics of the finished insulation are almost the same for all manufacturers, so there is no point in overpaying for the brand. The service life of this material is unlimited in comparison with other similar building materials.

On sale you can find various modifications of stone wool. A foil layer may be applied on one side to improve the heat-reflecting properties of the material. These rolls are insulated attic or attic rooms. The foil is laid in the direction of the room, which retains heat.

Roll cotton without foil is used for laying on the floor under a laminate, parquet or tile.

Conventional slabs are used to insulate the facade. A layer of external plaster is applied over them. There is also a shaped variety, which is two halves of a circle. They are used for warming water, gas, sewer pipes in the soil above the freezing level.

Stone wool properties

Natural stone wool has a number of positive qualities, which are recommended to be familiar with before choosing a heater for the home. First of all, it is fire safety, vapor permeability and durability. The remaining qualities are added to the basalt insulation during the production process - water resistance, environmental friendliness.

An important property of basalt rock is acidity. This indicator enhances the strength characteristics. To regulate acidity, carbonate additives are used to achieve the desired quality.

The binder, which is used for bonding basalt fibers, can be of synthetic origin, bitumen or bentonite type, as well as combined substances, which include several components. The most popular among manufacturers is phenol-formaldehyde resin. It is sprayed on small particles and form layers, which then harden. The amount of resin in the material is not more than 3%.

Fire resistance

The melting temperature of basalt in nature is about 1000 degrees, so stone wool is not afraid of fire. Any source of fire will not damage the material - when oxygen burns out, the fire will cease by itself.

When melting basalt in furnaces, a temperature of up to 1500 degrees is developed in order to melt the stone qualitatively.

Also, the material is not afraid of temperature extremes. When lowering them in winter, basalt fibers retain their shape well. This is important during construction, as several layers of plaster are applied to the slabs. If the substrate material shrinks and expands under the influence of heat and cold, the plaster will crack and collapse.

Thermal insulation

The thermal insulation properties of stone wool are that in winter it does not let the cold in, and in the heat in summer. The material allows air to pass through, so condensation and dampness will not form in the room.

The thermal insulation properties of stone wool are that in winter it does not let the cold in, and in the heat in summer. The material allows air to pass through, so condensation and dampness will not form in the room.

Soundproofing

The fibers in the production are located and solidify randomly, in addition, air bubbles are located between them. This provides good soundproofing properties. The thicker the layer, the worse it misses various sounds. A sound wave, falling on a porous material, is scattered and neutralized.

If you need to completely isolate the room from extraneous sounds, the walls are glued on both sides, and layers of cotton wool are laid on the door.

Durability

The durability of the material is not due to the stone component, but to the adhesive - glue. If it is of high quality, the material does not shrink over time and performs its functions well. This is important in the construction of underground water pipes in private homes and sewers. In the ground, in an aggressive environment, low-quality materials are quickly destroyed, and repairing a water supply system is expensive, given the complexity of the work. Therefore, saving on insulation is not recommended. Before buying, you need to clarify which substance was used for bonding and how durable it is.

The same applies to the external facade of a private house, where it is important that the cotton wool holds its shape and does not decrease in volume.

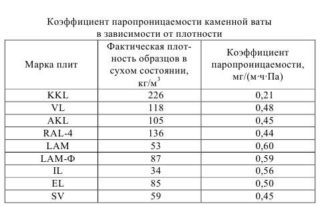

Moisture resistance and vapor permeability

After the formation of the layers, the cotton wool is treated with oil, which provides water-repellent properties. Due to this, water is not absorbed by the material. The porous structure allows the steam to leave the room, so mold does not form on the walls covered with slabs of basalt rock. To do this, manufacturers add other substances to the composition that kill the fungus. This property is used for warming rooms with high humidity - baths, pools.

After the formation of the layers, the cotton wool is treated with oil, which provides water-repellent properties. Due to this, water is not absorbed by the material. The porous structure allows the steam to leave the room, so mold does not form on the walls covered with slabs of basalt rock. To do this, manufacturers add other substances to the composition that kill the fungus. This property is used for warming rooms with high humidity - baths, pools.

Environmental friendliness

The question of the environmental friendliness of stone wool remains open. If it contains toxic substances that are used to connect the fibers, when heated, the material will release toxins in a small amount. Basalt itself is absolutely not harmful, as it is a natural stone.

It is not recommended to lay stone insulation without a protective mask. During installation, dust is formed containing harmful substances. Formaldehyde and phenol are dangerous toxic carcinogens that can cause allergic reactions to the skin and pulmonary edema when inhaled vapors. In the solid form, the resin is less dangerous, the migration of poisons is limited to the minimum permitted by the sanitary and epidemiological control.

Application area

Stone mineral wool has been used for quite a long time - since the middle of the 20th century, therefore it has established itself as a reliable building material. It is used:

- For insulation of external walls. This allows you to build buildings with less consumption of building materials. A layer of cotton wool of 10 cm replaces 2 meters of brickwork, which can significantly save on the construction of houses.

- For tying pipes from various materials. The metal does not corrode in contact with chemically neutral wool, so it lasts longer.

- To warm the internal walls of the house, as well as improve soundproofing properties. With single-layer brick laying, you can also increase the internal space by upholstering the walls with a thin slab of mineral wool.

- The material is laid under a concrete screed in the floor. This reduces sounds and also controls heat consumption.

- Roof insulation to prevent heat loss in the winter season, as well as additional room cooling.

- In the attic of the mineral wool, wooden parts are encased in order to protect them from accidental fire.

- Pipes in the apartment can be insulated with cotton wool to avoid condensation due to the flow of cold water.

It is believed that stone wool repels mice and other rodents. According to recent reports, this is not so. Animals feel good in natural material and make inside the nest, so it is recommended to use additional anti-rodent agents.

Options for insulating walls outside

For the facade, large-area slabs with a thickness of at least 100 mm are used. Suitable rolled, not glued with foil. Fastened with dowels or special glue for mineral plates. It is better to use both options at the same time. An important indicator for the facade is the density of mineral wool. It should be at least 45 kg / m3 cubic. Under decorative plaster, cotton wool with a density above 100 kg / m cubic is used.

Inside, the walls are insulated with mineral wool with a density of less than 45 kg / m3 cubic.

Floor insulation

For floor insulation, boards with a density of 30 to 45 kg / m are used. Lay it in a cell made of wooden blocks before pouring concrete. A film is placed under the layer of cotton wool for additional protection against moisture.

Advantages and disadvantages

Minerals from basalt have a few drawbacks:

- Depending on the resin used to join the fibers, the material may not be very safe. For use in institutions, hospitals, additional tests and certificates of quality are required.

- Does not scare away mice and rats.

- Additional safety measures are required when working with mineral wool.

The benefits are much greater:

- Low cost of material.

- Universality - can be applied in any rooms for external and internal works, as well as underground utilities.

- Incombustibility. Cotton wool is encircled in rooms where there is a risk of fire or flammable substances are stored.

- Hydrophobicity - does not absorb moisture and does not deform under its influence, although it passes steam well.

- It can stay in aggressive environmental conditions for a long time, without changing its shape and not crumbling into small parts.

- Installation can be carried out by a person who does not have experience in construction work.

There are requirements for the transportation of rolls and plates: during transportation, there should be no pressure on the boxes in which the material is located, therefore they are transported in an upright position.

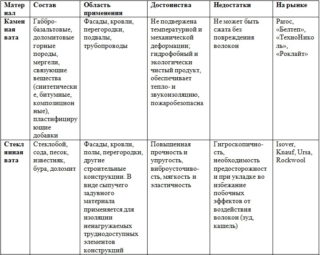

Which wool is better - mineral or stone

If we compare the types of mineral wool - glass wool or slag wool with basalt insulation, we can conclude by the following parameters:

- Basalt wool retains heat better.

- Glass wool is much more environmentally friendly, because it does not contain carcinogens that are used to combine basalt fibers. Glass wool includes glass and quartz.

- Slag is not used as insulation for residential premises. Glass wool and basalt insulation are more suitable for this.

- The density of basalt wool is higher, does not get wet, does not change shape. Glass wool is softer, while it is subject to moisture and shrinks. It is better to use glass wool in dry rooms or to insulate ground communications with it.

- No additional materials are needed for basalt. Glass wool requires a film to cover it from above and protect it from moisture.

- When using basalt wool, harmful dust is formed, since the fibers tend to break. Glass wool does not dust, as its fibers are long and soft.

If you perform internal work, it is preferable to use glass wool - it does not emit harmful substances into space, since the binder is acrylic resin - absolutely safe for health. For external work, basalt insulation is more suitable, since its moisture-repellent properties are much higher and the material does not respond to temperature changes, continuing to fulfill its functions.