One of the stages of the construction of private and municipal buildings is the implementation of insulation work. In most cases, mineral wool or penoplex is used for this, since these materials have the best performance against analogues. The comfortable atmosphere in the house and its service life depend on the choice of one of these heaters. In order not to be mistaken, the better to insulate the walls of the house outside, you should consider the features and characteristics of each product, taking into account all the accompanying factors.

Specifications

Mineral wool is a woven fiber obtained by heat treatment of raw materials passed through a supercharged chamber. Thermal insulation is made from volcanic rocks, steel slag and a mixture of glass battle with lime. The width of the mats and rolls varies between 60-80 cm, and the thickness is 10-40 cm.

Penoplex is made under pressure by extrusion. The heated mixture foams and then squeezes through the slots, where it hardens and takes the given shape. In volume, the material represents a porous substance, 98% consisting of air, which is the best insulator. The standard form of release is slabs with sides of 100 cm and 200 cm. The industry produces products with a thickness of 5 cm, 10 cm, 12 cm and 20 cm. For the finishing of window slopes, 2 cm thick PPP is produced.

To decide which is better, foam or mineral wool for wall insulation, it is worth starting by comparing the technical characteristics of both materials.

The data are presented in the table:

| Index | Mineral wool | Penoplex |

| Release form | plates, rolls | slabs |

| Installation location | inside Outside | inside Outside |

| Thermal Conductivity W / mK | 0.037-0.041 | 0.031 |

| Compressive Strength MPa | 0.01-0.02 | 0.05 |

| Density kg / m³ | 15-30 | 12-15 |

| Moisture Absorption Rate% | 4-10 | 1 |

| The coefficient of vapor permeability mg / mchPa | 0.1-0.5 | 0.03 |

| Price per square meter rub | 130-140 | 140-150 |

| Soundproofing effect at 1 cm dB | 6-10 | 7-9 |

| Years of operation | 30-50 | 30-50 |

Similar properties of foam and mineral wool

Making a decision when choosing between mineral wool or foam for insulation of an apartment is complicated by the fact that both materials have almost the same technical characteristics.

If the monetary factor in most cases is of decisive importance, here it can be ignored. The price of the plates is almost the same, a small difference is neutralized by the need to purchase additional finishes.

General properties of expanded polystyrene and mineral wool:

- Durability. Both heaters are designed for a minimum of 30 years. External factors do not affect the service life, because the materials are not susceptible to changes in temperature and humidity. They are avoided by insects, animals and pathogens.

- Excellent thermal insulation. This quality is the highest among the analogues on sale. Only polyurethane foam can be compared, but its price is much higher than that of plate heaters.

- Simplicity in work. Materials do not require special conditions of transportation and storage. They are lightweight, for installation there is no need to make efforts and attract assistants. Plates are easily cut and sawn with any improvised tools.

Comparison of similar indicators are only one side of the assessment of the characteristics of insulation. Differences should be taken into account, since in each case the building has its own characteristics and is operated in certain environmental conditions.

Distinctive properties of materials

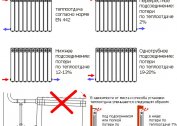

You can insulate the building from the inside and outside, the choice depends on the architecture of the building, its size and available finishing options.

You can insulate the building from the inside and outside, the choice depends on the architecture of the building, its size and available finishing options.

The following differences in the performance of the materials should be evaluated:

- Moisture absorption. If the foam is almost zero, then mineral wool can collect it up to 30% of its volume. This leads to a deterioration in insulating qualities and increases the load on the supporting structures. Damage to internal and external finishing materials is not ruled out.

- Flexibility. Expanded polystyrene is solid and practically does not bend. It can be laid on smooth surfaces without bulges and bends. There are no such requirements for mineral wool on the basis. Moreover, it can be mounted on uneven and even curved surfaces.

- Elasticity. At first glance, this quality may seem insignificant, but during the installation process it is noticeably manifested. The gaps between the polymer plates are inevitable, you need to spend time, glue and foam to seal them. Slabs of cotton wool are inserted in the form of disputes, plugging all the irregularities with their edges.

- Ways of exterior decoration. Expanded polystyrene only needs protection against ultraviolet radiation and mechanical damage. For this, plaster, plastic or metal siding is used. With porous plates a little more complicated. They require vapor barrier and a strong external fence.

- Mounting method. Foam slabs are fixed rigidly through screw-through to the base. It takes time and effort to apply the solution and drill. Wadded blocks simply insert into the frame, slightly squeezing their edges.

- Environmental Safety. Even in a static state, this indicator varies significantly. If the foam is neutral, the mineral wool releases many volatile fibers into the air. In contact with the skin and respiratory system, they cause severe irritation. The situation changes if the air temperature rises. With cotton there is practically no change. Expanded polystyrene melts, burns, releasing toxic substances harmful to human health.

- The rules of work. When working with polystyrene, it is enough to use gloves so as not to cut yourself with a knife. Installation of mineral wool involves a full range of protection - an airtight suit made of thick fabric, a mask and gloves. In addition, after the installation is completed, high-quality cleaning of the premises is required.

The listed aspects will serve as one more reason for reflection. A comparison of the pros and cons, general and different characteristics will allow you to make the best decision.

Areas of use

Both materials can be used for external and internal insulation of housing. It is clear that for a private home there are more such opportunities.

Mineral wool can be used for structures:

- Ventilated facade. The structure is a partition, which is installed at a distance of 3-6 cm from the walls of the building. The material on both sides is covered with a membrane sheet, and on the outside - with a rigid tiled finish.

- Frame insulation. It is often installed on the outside, as it takes up to 20 cm of usable area. It is used for decorating walls, ceilings, roofing and underground structures.

Due to its composition and physical characteristics, penoplex has a wider range of applications:

- Wet facade. This technology is a sequential process of gluing and screwing plates on the wall, reinforcing them with a grid, plastering and painting. It is used for finishing concrete walls, most often in apartments of multi-storey buildings.

- Warming of auxiliary facilities. This applies to floors, sheds, garages, pools, car washes. Plates perform well the function of insulation for the blind area, pedestrian walkways, undergrounds and cellars.When installed underground, penoplex does not need additional finishing, which reduces construction time and costs.

It is impossible to say unequivocally which material is better, since the choice is largely determined by the conditions of their operation.