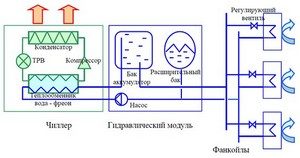

The chiller-fan coil system is a complex of climatic multi-zone equipment designed to create the optimal microclimate inside buildings with any number of floors and any area. The system is designed for continuous operation: in summer it provides effective cooling, in winter - air heating. The main elements are a heat exchange device and a cooler.

Elements and scope of equipment

The unit for cooling is a chiller. It is an external unit that produces and delivers cold through a set of pipelines inside which ethylene glycol or water circulates. This is a fundamental difference from split systems, where freon acts as a refrigerant, the transfer of which is carried out through expensive copper pipes.

The chiller-fan coil system uses conventional water pipes (metal or PVC) with reliable insulation. In this regard, the equipment is much cheaper. Outside temperature does not affect system performance. The split system loses its working capacity even at an ambient temperature of -10 degrees Celsius.

The operation of the indoor unit is carried out by a fan coil. With its help, the reception of chilled liquid and the transfer of cold into the room are carried out. After the liquid has finally warmed up, it is transferred back to the chiller. Fancoils are installed in each room and work on an individual program.

Scope of application:

- Hypermarkets

- large hotels;

- underground facilities;

- shopping malls.

To use the complex for heating, the program must be switched to a boiler or to the hot water supply to the fan coil to the second circuit. You can attach several fan coil units to one chiller. Such devices are mounted in the upper part of the room.

Equipment device

Chiller is a large capacity chiller. The heat exchanger discharges cold into the water. Water is cooled and flows to the fan coil through pipes.

There are 2 types of chillers: absorption and vapor compression. The first type is notable for its high cost, bulkiness and limited scope.

Steam compression chillers are more common. They are divided into types:

- outdoor installation with air cooling: the heat exchanger-condenser is cooled by axial fans;

- indoor installation with air cooling: the intake of air for cooling and the release of hot air is carried out using a centrifugal pump;

- with water-type cooling - it is advisable to install equipment near water bodies;

- Reversible - allow you to cool and heat the air.

Fancoils (closers) consist of a heat exchanger and a high-power fan. The product also includes a control device and easily removable air filters. Models are equipped with a remote control.

The fan coil system can be cassette or channel.

The purpose of cassette fan coil units is to cool or heat air space in large-volume rooms. False ceilings are required for installation. Air distribution occurs in 2 or 4 directions.

Installation of channel fan coils is provided in separate rooms. Air intake is through pipelines. Chilled or heated air is blown through air ducts located in rooms behind a suspended ceiling.Devices differ in installation method: wall, ceiling and floor. There are universal models.

Ancillary equipment

For the smooth functioning of the devices, devices and devices are used to expand the functionality of the equipment and make its work more efficient:

- a device for controlling the flow of the carrier of the cold;

- a gas boiler for heating water, which takes on the functions of a chiller in the cold season;

- expansion and storage tank compensates for the expansion of the coolant during heating.

The principle of operation of the chiller and fan coil

The principle of operation of the vapor compression chiller:

- The compressor absorbs gaseous refrigerant, the pressure inside the apparatus rises.

- Ethylene glycol enters the valve for thermoregulation. The pressure inside the device decreases and the refrigerant temperature rises. Ethylene glycol boils and partially evaporates.

- Boiling refrigerant enters the equipment evaporator, during the evaporation of which heat is taken from the water circuit. After passing through the evaporator, ethylene glycol again goes into a state of gas, the cycle repeats.

- With the help of a pump, chilled water enters the fan coil through a special pipeline. The closer, in turn, distributes the cooled air throughout the space of the room.

Fancoil works simply: the cooled water enters the heat exchanger, blown by air currents. The air passing through the heat exchanger is cooled and blown into the room.

Connection of chiller and fan coil

The chiller is combined with one or more fan coil units with an insulated piping system. If there is no insulation, the efficiency of the equipment drops significantly. Each fan coil is equipped with an individual strapping unit, which controls the performance of the device both in cooling and heating mode. The valves are responsible for the regulation of the refrigerant - shut-off and regulating.

The cold agent must not be mixed with the coolant. To heat water, a separate heat exchanger with a circulation pump is required. To ensure a smooth adjustment of the process fluid flow, you need to use a 3-way valve. The element must be installed during the installation of equipment. If a two-pipe type of heating is carried out in a building, heating and cooling are realized at the expense of the chiller. One of the available heat exchange systems is connected to a piping system with a refrigerant. The second is connected to a pipe with a coolant.

A special point is required to check the temperature of the water. The temperature index of the coolant in the system during the heating period varies from 70 to 95 degrees Celsius. For most fan coils, this temperature is too high and needs to be lowered.

Advantages and disadvantages of the system

The advantages of the equipment include:

The advantages of the equipment include:

- lack of restrictions on the length of pipelines between fan coil units;

- the ability to add or remove indoor units to an already running system;

- the absence of freon and other gases of a volatile type, which makes the operation of the equipment safe and environmentally friendly;

- use of one external unit.

The complex has gained popularity among representatives of medium and large businesses. However, it has disadvantages:

- significant noise level;

- the high cost of individual devices;

- low energy efficiency.

The chiller-fan coil system is used mainly in cases where the area of the premises and the building's features do not make it possible to use the split system as climate equipment.