The main task of a chiller-fan coil type air conditioning system is to create and maintain a given room temperature. Climate control is carried out due to the forced passage of air through the heat exchanger. Uninterrupted operation of the fan coil and other system components depends on the use of high-quality components and professional installation.

Components of the chiller-fan coil system

To maintain a comfortable temperature in large areas, a chiller-fan coil climate system is installed. In the warm season, it operates in cooling mode, and in winter heats the air. The main elements of the scheme:

To maintain a comfortable temperature in large areas, a chiller-fan coil climate system is installed. In the warm season, it operates in cooling mode, and in winter heats the air. The main elements of the scheme:

- Chiller - a unit that cools a liquid (water or ethylene glycol) circulating in a system. When paired with a fan coil, the machine provides multi-zone air conditioning. Her work does not depend on the temperature in the street.

- The carrier of cold and heat is water, a non-freezing mixture.

- Faynkol, fan coil or air conditioning closer - a unit with a heat exchanger and fan, which changes the microclimate in the served room. Design options: ceiling, wall, floor.

- Trunking - pipes made of polypropylene or steel. Its length depends on the power of the pump and the quality of the insulation.

- Tanks: expansion and storage.

- A pumping station that circulates the coolant.

- Automation unit.

The chiller and air conditioning unit are connected by piping. The connection is performed according to two schemes: two and four-pipe. In the first case, cooling and heating are performed by one chiller. The second option requires a separate heater and circulation pump.

Each fan coil is equipped with an individual strapping that regulates its performance.

Air conditioning benefits

- The scheme includes an arbitrary number of air conditioners-closers, which is determined by the capacity of the refrigeration unit.

- In each room, you can set an individual temperature.

- Considerable removal of fan coils from the chiller is allowed. Loss of temperature is prevented by thermal insulation of the line.

- The system operates in two modes: heating and cooling, eliminating the need for radiators.

- Using water or ethylene glycol as a refrigerant is environmentally friendly.

The main components and accessories of the air conditioning closer

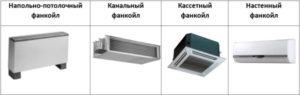

Fan coil units are installed in domestic, public and industrial buildings. They are placed in each room, maintaining a given temperature. The most demanded blocks are channel and cassette type. Climatic devices are mounted on the ceiling. Channel fan coils are designed for ventilation ducts, the cassette case is hidden behind a suspended ceiling.

Fan coil units are installed in domestic, public and industrial buildings. They are placed in each room, maintaining a given temperature. The most demanded blocks are channel and cassette type. Climatic devices are mounted on the ceiling. Channel fan coils are designed for ventilation ducts, the cassette case is hidden behind a suspended ceiling.

For work in apartments and private houses, wall and floor models of air conditioners-closers are used.

Principle of operation

Inside the unit there is a heat exchanger, in the tubes of which, depending on the season, cold or hot water (ethylene glycol mixture) circulates. A fan drives air out of the room through it. Forced circulation changes the temperature in the room. The air is heated or cooled to a predetermined value, controlled by a thermostat. Supply air is added to ducted air conditioners. In the process of working on the equipment there is condensate draining into a special tray.Moisture is removed by a drainage pump into the sewer network.

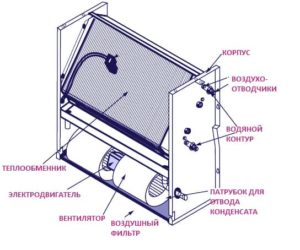

Structural elements:

- A heat exchanger is a unit made of copper tubes with soldered aluminum fins. Connection to the pipeline is made by couplings. The coil has valves for venting air when filling the system.

- Air circulating fan. In low-power equipment, tangential-type units are installed that operate with a low noise level. Medium and high performance units are equipped with centrifugal fans. Impeller is statically and dynamically balanced. A common option for turning on the electric drive is asynchronous three-speed electric motors for fan coil units powered by a single-phase network. The motor has anti-vibration mount. To reduce energy consumption and noise level allow brushless DC motors. The new drive reduces friction losses, smoothly regulates the operation of the fan.

- The filtering cartridge is a replaceable element of a frame type installed in the guides of the housing. The air supplied to the heat exchanger is cleaned by a filter. The device is a frame with synthetic material (polyester, polyurethane). Filters for fan coils are a replaceable accessory. During the operation of the unit, they capture dust and become contaminated. The unit needs periodic cleaning, otherwise the air condition in the room will deteriorate. After the recommended period has elapsed, the filters are replaced.

- Control unit (built-in or remote). The device regulates the fan rotation speed, changes the operating modes, sets the temperature parameters. Manage fan coil manually or using a thermostat. For wall and cassette models, the best choice is an infrared remote control. Precision adjustment is provided by wall-mounted control units and an integrated thermostat for the fan coil.

Strapping and mounting parts

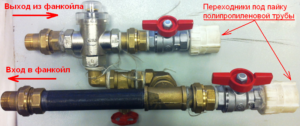

The air conditioner-closer is connected to the hydraulic module using mixing units. Valves for venting and removing coolant are available ready-made. Other parts of the harness are assembled separately. For hydraulic connection of the system, a balancing valve is installed. Its installation is not required.

Valves

Connecting the fan coil to the water supply system requires the installation of a strapping unit. The kit includes:

- valve seat type made of brass or steel with the function of "open / closed";

- electric servo;

- branch pipes for connection to pipes;

- mud filter;

- shutoff valves;

- thermometer, pressure gauge.

Mixing valve (two-way or three-way) - a device that regulates the flow of coolant. The control is carried out using a servo drive and a locking mechanism. The element is selected by bandwidth. The fan coil valve is available in two types:

- with quantitative adjustment of water supply;

- thermostatic mechanisms that change the temperature of the coolant, mixing it with the contents of the return line.

Fan coil operation principle

In the “open” position, the valve provides movement of the coolant to the heat exchanger. The signal from the control panel activates a spring rod with a lock washer, blocking the main line. In the “closed” position, the coolant flows along the bypass line.

Additionally, the harness is equipped with measuring instruments. The unit is located on the left or right side of the air conditioning closer. Installation is subject to the rules:

- The diameters of the pipelines correspond to the cross section of the heat exchanger fittings.

- All highways and binding units must be insulated.

- The connection of valves or flexible eyeliner to the fitting is carried out with two wrenches.

Fan coil adapter

Plenum for fan coil - part of the air conditioning system installed on the indoor unit for supplying air to the heat exchanger and distributing it in the room. The part is made of galvanized steel. The adapter allows you to connect the duct and duct air conditioning closer. When installed at the inlet, the plenum is equipped with filters. Adapters are available with dampers or valves to control the air supply. Depending on the design of the fan coil, plenums are made for each unit. An additional option is the technological sunroof device.

Eyeliner

For the convenience of connecting the air conditioning closer and the pipeline, not only piping with propylene fittings is used. Flexible fan coil eyeliner is a stainless steel tube with brass fittings at both ends. The plastic connecting element is durable, able to withstand water shocks. Quick connect metal hose suitable for cold and hot water. Rubber insulation prevents heat loss and condensation. Flexible eyeliner is relevant in areas with vibration.