The type of air conditioning engine affects the power and volume of the device, as well as energy consumption. There are several types of motors: collector, asynchronous and inverter. Knowing their pros and cons, it will be easier for the consumer to make a choice.

Manifold type engine

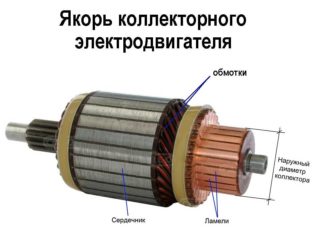

The collector motor of the air conditioner has a large starting torque element without special modifications. It is easy to configure, for which in the past it was popular with manufacturers of household appliances.

The collector motor of the air conditioner has a large starting torque element without special modifications. It is easy to configure, for which in the past it was popular with manufacturers of household appliances.

With the development of technology, the collector motor has become less popular for several reasons:

- Maximum productivity is 40 thousand revolutions per minute. This is not enough for an air conditioner. For example, this number of revolutions is comparable to the operation of a centrifugal juicer.

- Collector motors do not tolerate an aggressive environment, which in urban conditions quickly leads to damage to the device.

- One of the biggest disadvantages is the noise during the operation of the air conditioner. It is impossible to calmly speak, read and generally relax next to him. Moreover, the noise level of such devices sometimes exceeds the silence law, which may result in an administrative fine.

- With frequent work, you have to constantly brush.

- Graphite, used as one of the materials, constantly breaks.

Asynchronous motor type

The induction motor itself has poor starting characteristics, which requires a large amount of electricity to start it fully. The use in air conditioners is irrational.

The designers tried to solve the problem. However, the increased power of the induction motor required enhanced cooling, which again led to high energy costs. The control characteristic was worsened by an increase in the active resistance of the rotor.

Inverter motor type

Depending on the heat load in the room, the rotation speed of the compressor motor is automatically adjusted. It goes into forced mode until the temperature set by the user is reached.

Depending on the heat load in the room, the rotation speed of the compressor motor is automatically adjusted. It goes into forced mode until the temperature set by the user is reached.

Having reached the set values, the air conditioning fan motor reduces speed, while maintaining the desired temperature. This saves energy, as the compressor does not turn on and off continuously.

Air conditioners that work by turning on the compressor to reach the desired temperature and then turning it off wear out faster. This is due to the fact that when starting up for the first seconds, the device works without lubrication, as oil from the compressor flows into the crankcase.

Principle of operation

Using a power electronics unit allows the inverter motor to perform two sequential actions.

First, direct current is generated due to the mains AC voltage. Then an alternating current of the required frequency is formed from the resulting direct voltage.

The power inverter unit, like any other converter, has less than 100% efficiency. With long continuous operation at maximum speed, an air conditioner with an inverter type of motor will lose about 10-15% efficiency compared to devices of another type.

After reaching the indicated temperature, the inverter air conditioner operates in a mode of reduced compressor power, while other types of motors use a cyclic mode.

A non-inverter air conditioner during operation starts to experience maximum load during transients: both electromechanical and thermodynamic.

The rotor requires full return on all mechanisms, while they need to pump up to 50% of freon to the high pressure zone from the low pressure zone. During all these processes, the cold has not yet begun to be produced.

Having reached the desired indicators, the system through the throttling device equalizes the pressure in the upper and lower zones.

Freon boiling can occur in those parts of the air conditioner where it is not required: receiver, capillary tube, line. This is because the pressure during startup is too high.

For some time, the cold is used for other purposes: the compression compartment, the external unit, etc., are cooling. As a result, productivity is reduced.

Why choose an inverter air conditioner

It is necessary to highlight the positive and negative sides of the inverter air conditioner.

It is necessary to highlight the positive and negative sides of the inverter air conditioner.

Pros:

- longer service life compared to other types of motors: 8-12 years against 6-9 years;

- with the correct setting of the air conditioner's power, significant energy savings are possible without sacrificing comfort;

- thanks to the low-speed operation both on the indoor and outdoor units, the noise level is significantly reduced compared to other types of air conditioners;

- the speed of the compressor motor is smooth, making it easier for the device to maintain the set temperature with minimal deviations;

- quick setting of the preset mode: other models need about half an hour to start maintaining the set temperature; inverter motors reduce this process to 15 minutes.

The inverter motor of the indoor unit of the air conditioner has many positive aspects, however, there are also disadvantages that should be taken into account:

- long-term repair in case of breakdown due to the frequent lack of parts on the market; sometimes the wait for the right part is delayed for several months;

- during prolonged use without shutting down, increased energy consumption begins;

- due to the complexity of the electronic devices used in the engine's filling, it is sensitive to sudden voltage surges and may fail due to them;

- air conditioners with an inverter type of motor are more expensive than other systems for cooling and heating air.

Causes of malfunctions

Air conditioning repair masters identify several possible options that cause problems:

- If the motor shaft is backlash or abnormal noise, the bearings should be changed.

- If the engine stops spinning, you will need to change the starting capacitors.

- If the air conditioner fan motor stops a few seconds after starting, the Hall sensor is faulty. This electronic module is responsible for emergency shutdown of the engine in case of malfunctions, preventing its breakdown.

It is not worth it to take up work on your own, if there is no special knowledge. It should be entrusted to the master.

Air conditioner fan motor selection

In a split system, the engine is located in both the outdoor and indoor units. The fan motor of the outdoor unit of the air conditioner is made of metal, and the internal one is made of durable plastic.

Engine types:

- Multi-winding: different fan speeds are obtained by supplying energy to different windings.

- DC-inverter - most often used in inverter motors. By changing the amplitude of the DC voltage, the rotation speed is regulated.

- PG-motor - with the help of a regulating element (triac or thyristor) voltage is applied through a winding consisting of two parts. Different fan speeds are achieved by changing the amplitude of the control voltage.

Armed with knowledge, the user can easily choose the engine for the air conditioner and detect problems in the system in time.