Climatic systems have become a familiar attribute of apartments, offices, commercial and industrial buildings. Air conditioners of various brands and models cool the rooms, moisturize and purify the air. The operation of the equipment is controlled by electronic control units and sensors. Based on data from devices measuring temperature and pressure, the compressor is turned on and off, and the most effective operating mode of the entire system is selected.

Varieties of sensors

Turning on and off climate technology occurs without human intervention. It is enough to set a certain temperature once, and the system independently supports it. Devices that allow the air conditioner to function automatically are called sensors. They serve to measure certain technological parameters. The characteristics of split systems have a range of operating temperatures at which the manufacturer recommends turning on the equipment. Average indicators:

Turning on and off climate technology occurs without human intervention. It is enough to set a certain temperature once, and the system independently supports it. Devices that allow the air conditioner to function automatically are called sensors. They serve to measure certain technological parameters. The characteristics of split systems have a range of operating temperatures at which the manufacturer recommends turning on the equipment. Average indicators:

- in cooling mode from + 18 ° to + 45 ° C;

- in heating mode from -5 ° to + 18 ° C.

Premium models have a wider range of thermometer readings from -25 ° to + 55 ° C. The temperature sensor of the air conditioner determines the parameters of the air in the street and indoors, and also collects data on the nodes of the system.

Another group of measuring instruments controls pressure. The devices are installed in the freon line and open the control circuit when the indicator deviates from the norm.

Sensors differ in the level of design complexity, the simplest are relays, and the most advanced are chip-based systems. Devices prevent the breakdown of an expensive compressor.

Air purity is one of the parameters covered by the air conditioner. Multistage filtration systems allow you to bring it to a safe and comfortable performance. Special sensors determine the level of carbon dioxide, cigarette smoke, ozone, dust, various impurities and odors. When certain substances appear in the air, the device gives a signal to the filtration system. Ionizers, photocatalytic and bactericidal cleaners rid the room of odors, smoke, bacteria and allergens. As you clean, the color display of the sensor changes. These devices are rarely installed; they are equipped with multi-stage filtering models.

Air conditioner temperature sensors

The algorithm of operation of split systems is set by two main sensors: an air temperature sensor and an internal module evaporator. These devices are included in any standard equipment, including budget models. Climatic systems of middle and high class have more temperature sensors. Sensor devices vary in performance and resistance. Semiconductor thermistors are most commonly used. The principle of their operation is based on a change in the semiconductor resistance depending on a decrease or increase in the ambient temperature.

The algorithm of operation of split systems is set by two main sensors: an air temperature sensor and an internal module evaporator. These devices are included in any standard equipment, including budget models. Climatic systems of middle and high class have more temperature sensors. Sensor devices vary in performance and resistance. Semiconductor thermistors are most commonly used. The principle of their operation is based on a change in the semiconductor resistance depending on a decrease or increase in the ambient temperature.

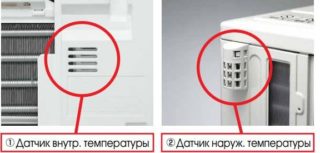

A device in the form of a drop is used to measure indoor air and outdoor air. The NTS temperature sensor for the evaporator and condenser is made in the form of a cylinder. On the back of the device is a contact connector for connecting to the control board, the parts are connected by wire.

The main characteristic of the temperature sensor is the nominal resistance, measured at 25 ° C.

For specific devices, it depends on the technical features of the equipment. Measuring instruments are installed in the external and internal unit of the split system.

Internal module:

- The room temperature sensor determines the operation mode of the compressor.

- Two indicators are installed on the evaporator, the device at the midpoint switches off the compression unit if the heat exchanger temperature drops below 0 ° C. This prevents icing on the assembly. The second sensor monitors the data at the input of the evaporator.

- A thermal sensor built into the fan motor prevents overheating and fire of the unit in the event of a short circuit.

- The terminal block temperature controller acts as a fuse when heated to 90 ° C.

Outdoor module:

- Condenser temperature control sensor - based on its data, the refrigerant pressure in the system changes. To take accurate readings, several sensors are installed at different points of the heat exchanger.

- Outdoor air temperature sensor - prevents the system from turning on at temperatures below the operating limit. The climate system blocks the start at low negative readings of the thermometer.

- The compressor discharge temperature sensor helps to determine the pressure; in case of exceeding the standards, the system gives an error code.

- A device is installed on the gas line that duplicates the operation of the low pressure sensor.

- The fan motor and terminal block are equipped with temperature sensors that are triggered by strong heating.

Possible malfunctions and replacement

Modern air conditioners are equipped with a self-diagnosis function. The devices test their own nodes, and if faults are detected, the corresponding codes are displayed on the display. The failure of the temperature sensor is the most common failure. The results of the vibration of nodes in sensitive sensors are confused. They lose the ability to accurately measure temperature.

Modern air conditioners are equipped with a self-diagnosis function. The devices test their own nodes, and if faults are detected, the corresponding codes are displayed on the display. The failure of the temperature sensor is the most common failure. The results of the vibration of nodes in sensitive sensors are confused. They lose the ability to accurately measure temperature.

Damage to the sensors will cause the air conditioning to lose its cooling function.

Touch devices are inspected visually to detect damage to the wire. In the absence of external malfunctions, they begin to diagnose:

- The sensor connector is disconnected from the board.

- The resistance of the device is checked with a multimeter or an ohmmeter, calling its contacts at minimum and maximum indicators.

- The screen will display data that must be compared with the nominal values indicated in the characteristics of the model. Discrepancies in numbers indicate a part breakdown.

- To troubleshoot, replace the temperature sensor. This spare part is not repairable. A similar brand of device is purchased, designed for the nominal resistance of the unit. For the internal module within 5-20 KOhm, for the external 10-50 KOhm.

Air conditioner pressure sensors

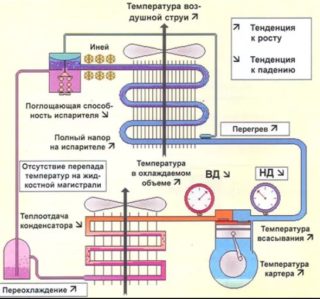

Freon pressure in the working circuit affects the operation of the climate system. An increase in the indicator threatens a rupture of the pipeline and leaks, a decrease reduces the intensity of cooling. In different parts of the line on the discharge and suction side, measuring devices are installed that monitor the technological parameters.

Freon pressure in the working circuit affects the operation of the climate system. An increase in the indicator threatens a rupture of the pipeline and leaks, a decrease reduces the intensity of cooling. In different parts of the line on the discharge and suction side, measuring devices are installed that monitor the technological parameters.

The air conditioner low pressure sensor shuts off the climate equipment when there is a lack of freon. Low pressure caused by a lack of refrigerant threatens undesired air leaks. The minimum indicator is 0.17 bar. The air conditioner high pressure sensor is installed in the liquid refrigerant pipe. It breaks the contact at a critical increase in pressure level above 27 bar. Devices protect the compressor motor from dangerous overloads.

Air conditioners are equipped with a different number of sensors and temperature sensors. Their presence allows the technique to conduct self-diagnostics and precisely adjust the set parameters.