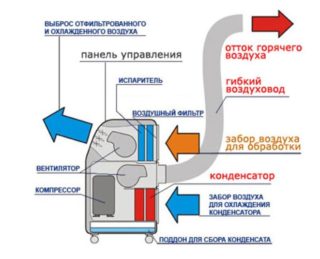

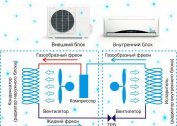

The principle of operation of an outdoor climate system, involving the installation of a corrugated pipe, differs from the principle of operation of a split system. A flexible duct for a mobile air conditioner is both a positive and a negative feature: on the one hand, it is possible to transport the unit, on the other, you need to find a way to bring the corrugation to the street. On this occasion, disputes and creative suggestions do not cease - which method is the best and most reliable.

Why corrugation is necessary and whether it is possible to do without it

To answer the question, you need to understand the models of floor air conditioners. They come with and without a duct. Both units have their pros and cons:

- Mobility is greater for a model without a corrugation - it is moved with the help of wheels and installed anywhere in an apartment or house. With corrugation, mobility is limited - a maximum of half a meter in different directions, while it cannot be lengthened, as this affects performance. The line increases, the compressor is forced to work harder to cool the room. If there is no temperature sensor, compressor power will be consumed on the longer corrugated pipe.

- For a model without a corrugated pipe, there is no need to look for a hole to remove air. At the same time, the efficiency of the device decreases, since the temperature in the room increases due to the compressor (it generates heat). Cooling is felt near the floor unit; it may not be enough for the whole room. Humidity is higher for models without an air pipe. In air conditioners with corrugation, moist air is removed, but the problem remains where to get the handset.

- The disadvantage of both models is the increased noise during operation, since the main components, including the compressor, are located indoors.

- A positive feature of both air conditioners is the ability to transport the device to another place for work. For example - to the cottage.

Corrugation for floor air conditioning - the ability to reduce humidity in the room, while maintaining a comfortable temperature in the summer in the heat.

How to choose a corrugated pipe for floor monoblock

Typically, an air conditioner duct is included with the equipment and does not need to be selected on its own. The problem occurs if it happens:

- damage to the part;

- loss or theft;

- it is necessary to lengthen the pipe for certain reasons.

In case of damage, the tightness of the structure is violated, warm air will flow through the holes back into the apartment. Therefore, the pipe must be replaced with a new one.

The duct must be lengthened in the following cases:

- The air conditioner model has too short corrugation, and the window or window is high. You must either install a monoblock on a hill, or lengthen the corrugation. At the same time, the power of the device decreases, because the volume of air discharged increases. The forums suggest installing additional pumps that will help to remove warm streams, but for this it is necessary to have knowledge and skills in order to independently select a pump and carry out the installation.

- The only place for fixing the corrugation is the balcony, but in front of it there is a loggia and the pipe does not reach the window. The loggia is large and will take most of the cold air produced by the equipment. As a solution to the problem, it is proposed to partially extend the corrugation, and to stretch the part of the pipe adjacent to the air conditioner as much as possible so that the volume of exhaust air does not increase much.

To choose the right model of the air conditioner, you need to calculate in advance the distance from the proposed installation location of the monoblock to the pipe outlet - this may be a door, window, window, sandwich panel at the bottom of the balcony door, wall.

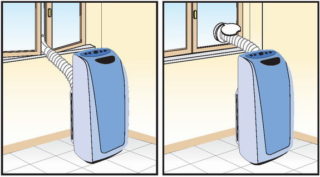

Where to get corrugation from a monoblock - offers and reviews

The easiest way is to make a hole in the sandwich plate. It cuts well, but you need to have special tools. Included with the equipment is an insert, which is mounted on the outside - it holds the pipe and creates a tight connection, preventing warm air from entering the room. The problem is that in winter this hole will let the cold through and it will need to be closed. There are removable frames in the frame that can be removed if desired. This is a rather expensive thing, as manufacturers charge money for convenience.

You can cut a hole along the diameter of the pipe in the glass and fix the holder from the outside. This is done both on double-glazed windows and on single glass. In summer, this design works well, but in winter it also needs to be closed so that the room does not cool. If the monoblock works for heating - another matter. This will be his permanent location. The output is as follows:

- have two double-glazed windows and change them depending on the time of year;

- replacing a sandwich with a plate for summer and making a hole in it is the most aesthetic solution;

- output into an ajar window or an open window, but in this case, cooling will not be effective, because warm air will penetrate through the slot.

The next option is not to touch the glass, but to make a hole in the wall exclusively for the monoblock. It all depends on the thickness of the building material - concrete, brick. Special tools are needed to make a hole with smooth edges and not damage the structure. Some people on the forum are familiar with the new technology of diamond drilling, which can even cut reinforcement in concrete, which is applicable for load-bearing structures. For ordinary walls, a puncher or hammer drill is used.

The price of work is high, but in the absence of other opportunities, you will have to pay. Drainage in the absence of a special pan can be discharged into the same hole.

The ventilation hole in the wall has its drawbacks. One of them is the intake of cold air in the winter season. In this regard, they suggest using mineral wool and closing a hole in the wall with it. An acceptable but not aesthetic option. Violating the integrity of the bearing walls is allowed individually, first you need to get permission from the architect. Otherwise, you will have to pay a fine and make repairs for your money.

How to build corrugation for monoblock

To compensate for pressure loss with increasing duct length, the following measures can be taken:

- Lengthen by no more than 1 meter, while leaving the diameter of the one that has the main pipe. If this is enough to bring the corrugation out, the losses will be negligible.

- Leave a piece of corrugation of standard diameter, connecting a thinner tube, but a long one, to it through the adapter. It must be borne in mind that the volume of air passing through the pipe is from 230 to 260 liters. Air resistance is greater in round ducts than in a square section.

Attach to the outside of the glass or wall in an airtight manner. To do this, use dowels, which screw a plastic or iron nozzle holding the corrugated pipe for the floor air conditioner.

If there is no desire to pay for the installation of a special insert, you can independently connect the corrugated hose, using the experience of people who already have monoblocks.