Installing a split system is an additional cost. Pay professionals or perform the installation yourself, the owner of the climate technology decides individually. Installing an air conditioner is a responsible procedure, the cooling efficiency and the life of the equipment depend on it.

Installation materials and tools

The installer's task is to fix the external and internal unit in the selected places, connect them with a trunk and connect to the power supply. The mounted system is evacuated, filled with freon and tested.

To perform the work, special tools and equipment will be required:

To perform the work, special tools and equipment will be required:

- punch with a diamond drill with a diameter of at least 45 mm;

- Vacuum pump;

- pipe bender;

- rolling;

- gauge manifold;

- pipe cutter;

- rimmer-stripping.

Installation materials:

- 2 copper pipes with plugs at the edges, the length is equal to the length of the trunk plus a margin of 20-30 cm. The diameter depends on the recommendations of the equipment performance, the higher it is, the larger the cross-section of the route. A common 1/4 and 3/8 inch option is to feed and return the freon.

- Plastic box, inside of which there is a freon track and electrical wiring.

- Electrical cable. The wire cross section depends on the power of the split system: up to 3 kW - 1.5 mm2, 3-5 kW - 2.5 mm2, 8 kW - 4 mm2.

- Corrugated or polypropylene plumbing drain pipe with a length of 80 cm longer than the line between the blocks.

- Thermal insulation for the Freon route - K-Flex rubber sleeve. The material is durable, has low thermal conductivity, fireproof. It will prevent refrigerant energy loss.

- Brackets for mounting the outdoor unit - metal corners designed for a load 2 times the weight of the equipment.

- Fasteners (bolts, anchors, plastic clips).

When choosing the wall thickness of copper pipes, the type of refrigerant is taken into account. In systems with R410A freon, the pressure reaches 26 atmospheres, and for R22 - 16. In the first case, a thick-walled trunking device and better flaring are required.

Air conditioner installation instructions

Monoblock options for HVAC equipment for the apartment are available in window and mobile type. The first option is installed in the window opening, and the second does not require installation. It is enough to organize the outflow of air out through a special hose. A common type of air conditioner is a split system, selected in accordance with the area of the room. The stability of its operation depends on the quality of installation. Climatic equipment consists of two blocks:

- external - capacitor;

- internal - an evaporator, may consist of 2-4 modules, this combination is called a multisplit system.

The first is always the external unit. The system is connected by a line of copper pipes through which refrigerant circulates. A drain hose is discharged from the indoor unit. According to the rules, he goes to the sewer. This is an expensive and complicated procedure. In practice, condensate is vented outside. The design of the air conditioner does not affect the installation principles. The rules for placing blocks for different models are almost identical.

Choosing a place and fixing the outdoor unit

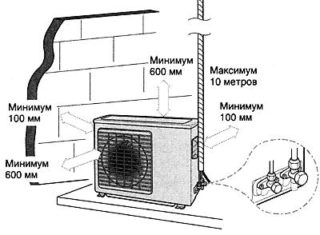

A place for an external unit is selected, taking into account the following criteria:

A place for an external unit is selected, taking into account the following criteria:

- side of the world (the south is not recommended due to the heating of the technique by sunlight);

- the presence of trees - leaves and other debris will clog the air conditioner;

- wall material;

- mass of the external unit;

- accessibility for after-sales service;

- weather protection.

Common installation options: to the right or left of the window, under the window, on the balcony. If the apartment is located on the ground floor, the unit is mounted at a height of at least 2 m from the ground. Installation of split systems on the facade of a multi-storey building is carried out by climbers. Given the cost of their services and subsequent maintenance, the option of installing the external part of the air conditioner on the balcony is relevant. The equipment will be sheltered from the weather, the repair and refueling of equipment will be simplified. Requirements for a balcony: no glazing or wide-open windows to remove heat. Installation Rules:

- The distance from the outdoor unit to the wall is 15-20 cm. The gap will create conditions for heat dissipation and laying the track.

- Fastening is carried out not to a ventilated facade or insulation, but to a solid foundation (concrete, brick).

- The external unit is installed horizontally, at the same level or below the internal part.

- The length of the connecting line should not exceed 6 m. A longer duration requires an increase in the volume of freon, there are cold losses in the system.

- Water from the drain pipe should not fall on the wall and drip on passers-by.

Before installing the air conditioner, they must get approval from the housing office. It is forbidden to attach equipment to the facades of buildings of historical value.

The metal visor above the unit will protect against icicles falling from the roof and other negative effects. It is installed after laying the highway with freon. The visor should not lie close to the wall; a clearance is required for air movement. When choosing the location of the external module, it should be noted that the noise of a working air conditioner may disturb neighbors.

Mounting the indoor unit

The best option is to place the indoor and outdoor units of the air conditioner on the same wall. This will reduce the length of the freon route and ensure high efficiency of air cooling. Before installation, check the wiring power. If it is not enough for an additional load of 2 kW and above, a separate cable is drawn from the distribution panel. According to the installation rules, the climate system unit can not be placed:

The best option is to place the indoor and outdoor units of the air conditioner on the same wall. This will reduce the length of the freon route and ensure high efficiency of air cooling. Before installation, check the wiring power. If it is not enough for an additional load of 2 kW and above, a separate cable is drawn from the distribution panel. According to the installation rules, the climate system unit can not be placed:

- over heaters;

- below 1.5 m from the floor;

- behind curtains, curtains and other objects that restrict air circulation;

- less than 15 cm from the ceiling;

- next to the furniture;

- above the workplace or bed to prevent colds.

Provide unhindered access to the air conditioner. It will be required when servicing, replacing and cleaning filters.

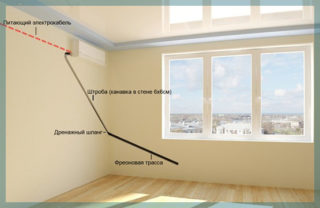

To connect parts of a split system, a hole with a diameter of 45-50 mm is drilled in the wall. A sleeve is inserted inside to waterproof the wiring and pipes, reducing the likelihood of damage. The hole breaks through with a bias towards the street to drain the condensate. The air conditioner comes with the mounting plate for the indoor unit. It is mounted horizontally, checking with the building level. The holes are drilled, installation is done with dowels. After fixing the unit with special latches, the horizontal plane of the installation is checked.

Electrical wiring

The standard option for connecting household air conditioners with a small power of 1.5-2 kW is an existing outlet. With insufficient wiring power from the shield, a separate cable is laid with copper conductors: 3 - single-phase connection, 5 - three-phase connection. Wire cross section 1.5-4 mm2. A circuit breaker (RCD) is installed in the shield. Under the front panel of the air conditioner there are terminals for connecting wiring. The manufacturer's instructions outline the procedure. Before connecting, each core is stripped with protective insulation. The end is inserted into the terminal and clamped by a screw.

From the indoor unit, the cable is routed to the outside. Numbered terminals are located under the capacitor cover. The wires are connected according to the marking.The electric cable is placed in a corrugation and mounted in conjunction with a copper pipe. Communications stacked decorative box.

Freon Routing

The freon circulation line consists of two copper pipes of different diameters. The material is sold in bays, from which the desired length is cut. The work is carried out by a pipe cutter, it is not recommended to use a hacksaw, which clogs the inside with chips and does not guarantee a smooth cut. During installation, the ends of the pipes are closed with plugs to prevent debris.

The freon circulation line consists of two copper pipes of different diameters. The material is sold in bays, from which the desired length is cut. The work is carried out by a pipe cutter, it is not recommended to use a hacksaw, which clogs the inside with chips and does not guarantee a smooth cut. During installation, the ends of the pipes are closed with plugs to prevent debris.

In the right places, the highway bends with a pipe bender. Using a special tool eliminates dents and cracking of the metal. A heat-insulating sleeve is put on top, the joints of the insulation are fastened with reinforced tape. If the installation of the air conditioner coincides with the repair, a wall plug is installed in the wall for flush mounting. Typically, communications are mounted outside the enclosing structures, excluding dusty cutting of concrete. The components of the highway are wrapped with insulating tape from above.

Threaded flanges are put on pipes with insulation. The ends of the tubes are expanded. The work is done carefully, there should be no cracks and grooves. For self-assembly of a split system, installation kits are offered. They include all consumables:

- 2 copper tubes with a diameter of 6.35 and 9.52 mm with a heater, flared edges in the factory and put on brass nuts;

- corrugated hose for drainage;

- electric cable with a cross section of 1.5 mm2;

- brackets for mounting the outdoor module.

When laying the highway, complex bends and differences in height are avoided.

After being brought out, they are attached to the wall with clamps with an interval of 0.5-0.6 m. The classic track is characterized by a length of 3-7 m and a simple configuration. Flared tubes are connected to the respective block fittings. First, the nut is twisted by hand, then crimped with a torque wrench. The tool helps to control the degree of tightening. Excessive efforts lead to cutting of the flared part, and insufficient sealing to the loss of freon.

Drainage

Simultaneously with the installation of the pipeline, condensate discharge is arranged. The drainage hose is laid with a slope that provides gravity of water or install a drainage pump. The pipe is connected to the corresponding output of the indoor unit and displayed on the street or in the sewer.

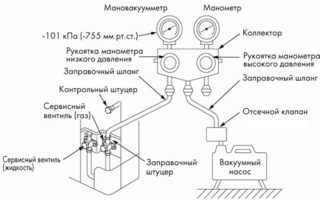

Evacuation system

The smallest particles of dust, air and moisture are removed from the system using a vacuum pump and pressure gauge. One manifold hose is connected to the spool of the filling port, the second to the vacuum pump. The unit turns on, the manifold valves open. The removal of air and water from 20 to 45 minutes, the duration of the procedure depends on the length of the line. Evacuation ends when the pressure gauge needle shows a pressure of -1 bar.

The smallest particles of dust, air and moisture are removed from the system using a vacuum pump and pressure gauge. One manifold hose is connected to the spool of the filling port, the second to the vacuum pump. The unit turns on, the manifold valves open. The removal of air and water from 20 to 45 minutes, the duration of the procedure depends on the length of the line. Evacuation ends when the pressure gauge needle shows a pressure of -1 bar.

The design is not disassembled within 30 minutes. During this period, the pressure gauge is monitored. If they remain unchanged, the work is over. Deviation of the arrow to zero indicates a leaking system. Typically, problems arise at the junction of copper pipes and air conditioning fittings.

It is not permissible to replace evacuation by purging the system with freon. Moisture remains on the pipe walls, reacting with the refrigerant. The oxidation of the walls of the pipeline.

Air conditioner filling and testing

After checking the tightness of the system, they begin to fill it with refrigerant. A hose is already connected to the service port, it should not be removed until the end of the freon injection. The hex key opens the liquid port port valve. Freon movement through the system is indicated by characteristic noise. After filling, unscrew the hose from the gas valve. Work requires safety measures.Hands are protected from the release of freon by gloves, and eyes with special glasses.

Hissing, the release of a small amount of oil and refrigerant is normal. The fitting is quickly closed with a plug, eliminating the loss of freon. Installation of the air conditioner is completed, you can turn it on for testing. Starting to check, close the windows and doors in the room.

The main connection errors and their correction

Self-assembly of split systems and engaging inexperienced installers with work results in connection errors. Typical flaws:

- Placing the indoor unit in a niche, near cabinets and other dimensional furniture. Violation of air circulation leads to freezing of parts, leakage. The rational option is to perform a permutation. Moving furniture is easier than installing the internal module in a new place.

- The lack of high-quality thermal insulation of the pipeline and the place of output to the outside leads to the appearance of condensate. High humidity provokes the development of the fungus.

- Poor flaring degrades the circulation of freon, the tubes do not fit the fittings badly. Refrigerant is leaking.

- Collisions (kinks) of the highway reduce the throughput of the route, increase the load on the compressor. The unit operating in abnormal mode quickly wears out and breaks.

- Not enough refrigerant. The length of the pipeline above the standard requires a proportional increase in the amount of freon. A lack of refrigerant reduces the performance of the air conditioner. It is necessary to refuel the system.

- The appearance of moisture under the indoor unit due to skew during installation. The air conditioner is not installed horizontally, condensate from the drip flows to the floor.

- The appearance of a knock from the outdoor unit due to weak fasteners or installation on a vibrating base without special linings. The situation requires an early correction of deficiencies. Fasteners are pulled to a reliable level.

- The outer wall is getting wet. A short drain hose provokes moisture to drain off the façade. The tube is extended to 80 cm, excluding wetting of the load-bearing wall. In winter, the hose may freeze, if the split system is to be used in the cold season, a heating cable is required.

- Installation of an air conditioner in a room where there are devices with high-frequency vibrations (drilling machines, welding machines).

- A stream of cold air creates a draft. Correct the problem by adjusting the position of the front panel flaps.

The cost of installing an air conditioner depends on the power of the model, the location of the apartment (the work of climbers at a height will cost more), the material of the walls. Each meter of the route in excess of 5 m is paid separately. Taking into account consumables, the price of a standard installation is approximately equal to one third to half of the cost of a split system.