Repairing an air conditioner with your own hands will significantly save not only money, but also time. But not every amateur can cope with any job, because air conditioning is a complex equipment. Often, special diagnostic tools are required. Breakdown detection is facilitated by the presence of self-diagnosis systems.

Diagnostics

To eliminate breakdowns of climatic equipment, craftsmen are invited from the service center. But in the summer season they are inundated with work for 2 weeks in advance. To wait until the master is free is long and uncomfortable, because the temperature in the apartment rises to 30 degrees. If you have tools, you can try to fix the breakdown yourself. To do this, you need to have minimal knowledge about how the air conditioner works, which is easy to find on the Internet by watching a couple of videos about repairing household split systems.

If the air conditioner does not turn on, perform the following diagnostics:

- Make sure that the module is connected to power: turn it off and turn it on after a couple of minutes.

- Do the same with the remote control, change the batteries in the remote control.

- Check the integrity of the wiring and the machine.

If none of the above actions has yielded results, the repair of a household air conditioner will have to be entrusted to professionals.

The first thing that the wizards do is test the device according to the main parameters:

- check the filters and the drainage system for cleanliness - power may decrease due to poor air circulation in the system;

- measure current and voltage in the network - in old houses the wiring sometimes does not withstand the load, with power surges, modern devices do not turn on, as they are specially protected;

- electronic master checks the board; modern air conditioners have a self-diagnosis function and give error codes, so it’s much easier to figure out what exactly “flew”;

- the banal causes of equipment failure to turn on are considered - improperly selected operating mode, the appearance of heating devices near equipment, inconveniently located blinds;

- check the sealing of the system and the amount of refrigerant;

- inspect the compressor, as it may break due to the inclusion in the winter season of heating without a winter kit.

All breakdowns, except for the last two, can be fixed independently.

To repair or replace the compressor, contact the service center of the company from which the equipment was purchased. Sometimes wizards need to be called to repair the electronic control board, since this is a finer job than washing the filter or replacing it.

Common problems and their solutions

Drafts

Strong blowing towards people increases the risk of colds. The reason is the incorrect position of the air conditioner blinds. They are installed in a horizontal position and the problem goes away. There is a self-oscillation function of the blinds. The instructions describe how to use the remote control to configure it in this model of air conditioner.

A more difficult way out is the installation of a protective screen, which is ordered on the Internet or bought in building supermarkets in the climate technology department. Installing the screen yourself with tools is a matter of 15 minutes.

Condensate

Dripping from the indoor unit is one of the most common complaints at service centers. The cause of the breakdown is clogged drainage pipes. In this case, you can repair the air conditioner with your own hands.Typically, the drain pipe is plugged with an ice plug when the equipment is turned on in cooling mode when it is frosty outside.

Repairing the air conditioning tubes may not be necessary if you wait until the temperature rises above zero. The ice will melt by itself, the equipment can again be used.

Under no circumstances should you start the air conditioner to cool if you suspect an ice plug. This will lead to overhaul of the tubes.

Filters

Poor cooling, droplets of water on the housing are signs of clogged filters. Thorough and regular cleaning - all the necessary manipulations.

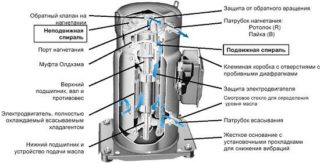

Compressor problems

Problems with a lack of freon and compressor are associated. If water gets inside the system, the compressor parts are corroded. In addition, it overheats, which will be indicated by the black color of the oil. The acidity test of the oil will clarify that metal salts are present in the circuit.

Due to a malfunction in the electronics system, the compressor also suffers, therefore, the refrigeration circuit, electronic systems, and then the heart of the air conditioner, are diagnosed first.

DIY repair is not possible with the following breakdowns:

- Leak of freon, which is determined by freezing of the fitting connections of the external unit. The master has specific equipment that is not available to most users with household split systems. If the four-way valve is damaged during overheating, it is replaced.

- Marriage during the installation of copper tubes - for example - creases. The main line is reinstalled, which an ordinary person without tools is not able to do. Lack of evacuation is a serious minus of installers. Blowing the system with freon does not remove water vapor that causes corrosion of compressor parts.

- Incorrect wiring between the outdoor and indoor units.

- Incorrect connection of wires leads to malfunctions in the electronic board, which sometimes requires its replacement due to the fault of the installers.

It is not recommended to troubleshoot the electrical part of the air conditioner without knowledge of the case. This is fraught with negative consequences.

The compressor is replaced in two ways:

- Without flushing the external unit. If the oil has a light shade when draining, the acidity analysis is not increased, it does not contain any foreign particles. The compressor changes, the system is evacuated and tested.

- The washing of the external unit is necessary when the oil analysis showed increased acidity, the presence of dirt in the circuit and metal particles that got there after poor-quality pipe trimming.

The procedure is complicated, repairing a split system with your own hands is impossible in this case. It is made by masters with special devices that remove extraneous inclusions from all inaccessible places of the freon highway so that the problem does not recur.

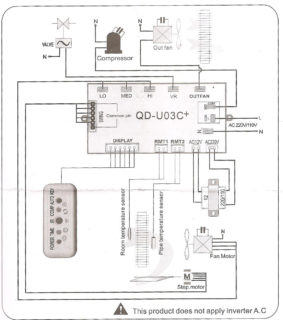

Management board

Repairing an air conditioner board is a task for a specialist. Boards of different manufacturers differ from each other. In addition, even the power supply to the boards is carried out in different ways. Some are equipped with three-wire wiring, others - single-core. A self-diagnosis system notifies you of some problems, but in most cases special instruments are needed, for example, an oscilloscope. The control system is protected by a diode bridge, a varistor and a zener diode. Breakdowns are likely during network congestion.

DIY troubleshooting

The following repairs are performed independently:

- Elimination of simple control and equipment errors - batteries, mode.

- Cleaning the filters with detergents or a vacuum cleaner.

The rest of the work - oil change, compressor repair, relocation of the trunk, adjustment of electrical wires is carried out by professional craftsmen.If a noise is heard when the equipment is turned on and the device does not begin to fully work after 3 - 5 minutes, it is turned off and repairmen are called.