A precision air conditioner is a device that not only cools or heats the air, but also precisely maintains the values of its several basic parameters: temperature, humidity and mobility. Such units belong to industrial equipment.

They find their application in rooms where round-the-clock and year-round creation of a suitable atmosphere for electronic equipment is required, and with maximum accuracy. Deviation from the norm in temperature and humidity in most of these rooms is allowed a maximum of 1 ° and 2%. Server rooms, rooms with telecommunication equipment, operating rooms in hospitals, research laboratories, burn centers and similar facilities require the installation of precisely such high-precision climate equipment.

Types of precision air conditioners

There are several types of air conditioners. They can be divided relatively:

- constructions - monoblock, ceiling and precision cabinet-type air conditioners;

- type of condenser cooling - air, water, mixed;

- number of circuits - single-circuit and double-circuit devices;

- modifications (modes) - only cooling, cooling + humidification, cooling + heating, cooling + heating + humidification.

Monoblock devices are suitable for small and medium-sized rooms. They usually consist of a compressor, condenser and evaporator heat exchangers, condenser and evaporator fans, and an air filter. Their power rarely exceeds 20 kW, and they have the ability to change the direction of air supply.

The cabinet type air conditioner, whose power reaches up to 100 kW, helps to remove excess heat from equipment in larger rooms. Such an aggregate consists of one or two blocks - internal and external. The first one contains all the elements of the refrigeration circuit, electrical components and automation. The external unit can be represented by a remote condenser, a condensing unit or a chiller (liquid cooler). They work quietly and with a high level of accuracy.

Ceiling systems are also installed in small rooms. Their power varies on average from 3 to 20 kW. Neat dimensions allow you to put them where the cupboard air conditioner is not possible to place. They can work in natural and mixed cooling mode, almost without making noise. Automatic protective algorithms prevent damage to the device, and for some devices the fan continues to work even after an accident. Management is usually carried out from the controller through integration with the dispatching system of the premises served.

Principles of operation of precision air conditioners

Several principles of operation of precision air conditioners are distinguished depending on the type of cooling and the number of circuits.

Air-cooled systems are distinguished by the most familiar refrigeration cycle scheme, similar to a conventional split system. Freon under pressure is compressed in the compressor, and then enters the condenser, where it goes into a liquid state. From here it passes through a thermostatic expansion valve (TRV), and its temperature drops there. Once in the evaporator, Freon again goes into a gaseous state and enters the compressor again. In this case, the air is cooled as it passes through the evaporator and exits. Heat is removed from the condenser by a fan.

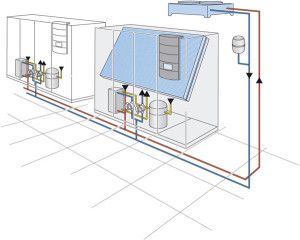

You can see the scheme of operation of a precision air conditioner with an external air condenser in this photo.

This principle of operation of precision air conditioners does not differ much from the cycle diagram of the device with a drycooler. The difference is that heat is not released through the fan, but into the water. In the indoor unit, a freon-water heat exchanger is installed, to which an external (drycooler) with a water pump is connected. Heat transfer occurs through the heat exchanger, and its discharge to the street is due to the fan of the outdoor unit.

If the air conditioner has water cooling, then it is usually combined with a chiller. In the indoor unit, the air is cooled using a coolant, which lowers its temperature in the liquid cooler.

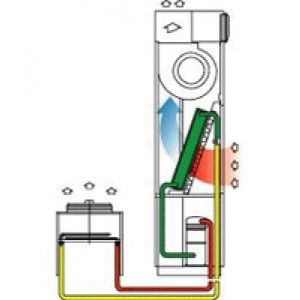

This photo shows the operation of a precision water-cooled air conditioner through a chiller.

For precision air conditioners with a double circuit, a different principle of operation is characteristic, in which the air from the servers enters the evaporator of the indoor unit of the precision air conditioner and cools there, from there it already enters the room. The thermal load thus removed is transferred to a condenser integrated in the internal unit of the device and cooled by water, and then transferred to the water circuit. From here the heat leaves with the help of a drycooler and is vented to the atmosphere.

Air supply and intake

The intake and delivery of air from precision air conditioners can also take place according to different schemes:

- lower fence / upper output;

- upper fence / lower delivery;

- fence from the front / top delivery.

If the air outlet is from above, then it passes through the upper panel of the device; at the lower outlet, a raised floor is usually installed, through which the air is distributed through the air distribution space.

type of instalation

There are precision air conditioners for indoor and outdoor use. The former are used when it is necessary to integrate the device into an existing system or when there is not enough space in the room. This is a very economical air conditioning option as the standard outdoor air conditioner has the option of free cooling using outdoor air.

As a rule, these are monoblock systems that can be controlled remotely or by a thermostat.

Indoor installation is typical for cabinet and ceiling precision. During installation, two holes are cut for them, through one of which the condenser will be cooled.

If the device is mounted on the street side, then two holes are also cut during installation. Air will pass through one of them to cool the room, and through the second, the exhaust from the room will go. With outdoor installation, a mixture of fresh low-temperature air is mixed, and thus the air conditioner works due to free cooling, the so-called FREE COOLING.

Installation of precision air conditioners

Installation of any precision air conditioner requires detailed planning and extensive experience from the craftsmen. It takes place in several stages:

- Selection of a place for installation, taking into account the location of heat sources, surrounding objects and protective mechanisms (visor and grille). The allowable path length and elevation differences between the blocks are taken into account.

- Reliable mounting of the external unit on the brackets, taking into account vibration during operation. Be sure to leave access to the module for maintenance.

- Reliable fastening of the indoor unit, taking into account the distance from sources of heat and other objects in the room. Space is provided for normal air circulation. The slope of the module is allowed no more than 5%.

- Laying inter-unit communications. Drill holes in the wall through which the drainage hose, freon route and electrical cables pass.If you have to exceed the permissible line lengths and elevations, it is necessary to install loop traps in the pipeline to reduce the load on the compressor. They monitor the quality of the route sealing and cable insulation. All communications are packaged in a special pipe and vinyl tape, and then dragged through the holes in the wall.

- Connection of a precision air conditioner according to the electrical circuits that are given in the technical passport, as well as on both blocks.

- The last stage is evacuation of the system and trial run of the installation.

It is worth remembering that some precision devices have humidification systems that require separate settings.

Maintenance of precision air conditioners

An important role in trouble-free operation is played by regular maintenance of precision air conditioners, which is carried out at least once a quarter. The frequency depends on the location of the device and the level of its load. What is included in preventive measures?

Standard service activities include troubleshooting and cleaning / replacing some items. Diagnostics consists of:

- checking the condition of the interblock route and electrical communications;

- testing operating modes;

- measurements of the compressor current, the level of freon in the circuit and the issued air parameters.

Preventive work consists in:

- checking the condition and, if necessary, cleaning heat exchangers, fans, filters and the front of the air conditioner;

- replacing filter elements and steam cylinder.

If malfunctions are detected during the maintenance of a precision air conditioner, repair and restoration work may be required to replace damaged parts and mechanisms.

Popular brands in Russia

The most popular and sought-after brands of precision air conditioners in Russia are considered UNIFLAIR, Liebert, EMERSON and BLUE BOX.

UNIFLAIR

The Italian company UNIFLAIR produces several series of very compact monoblock, ceiling and cabinet type appliances with installation both inside and outside the room. Their power varies from 3.9 to 168.7 kW. Among them there are devices with air, water and natural cooling. TWIN-COOL models have a dual cooling circuit. Air blowing occurs frontally, from above through air ducts or a suspended ceiling and from below through a raised floor. There are series with the function of free-cooling.

All UNIFLAIR precision air conditioners are energy efficient machines that can operate even at extremely low outdoor temperatures (up to -40 ° C).

Maintaining a normal level of humidity and temperature occurs with an accuracy of 2% and 1 ° C, respectively.

The equipment works seamlessly with smoke, fire and water leak detectors. It is combined with building climate control systems. The average life of a UNIFLAIR precision air conditioner is 10-15 years. These are reliable chillers that are ideal for archives, museums, medical facilities, telephony centers, server rooms and hardware.

LIEBERT & EMERSON GROUP

Another world leader in the market for HVAC equipment is LIEBERT (EMERSON) precision air conditioners, which are able to maintain specified parameters to the nearest tenth of a degree and percent.

Several decades ago, the two companies LIEBERT and EMERSON joined together and began to produce climate equipment for industrial facilities. Precision air conditioners EMERSON, LIEBERT HIROSS operate at extreme temperatures in summer and winter and, subject to operating conditions, can last for 10 years continuously. Power variability - from 3.5 to 160 kW.

The company produces a separate line of air modules with a nominal value of 1.2 kW. These mini machines are designed for installation on the door or wall of cabinets with electronic equipment.

Several lines are represented by cupboard monoblocks and two-component systems of indoor and outdoor installations with air, water and natural condenser cooling modes. The most efficient and economical models are LIEBERT precision air conditioners with two cooling media and redundant compressors. Management is carried out by a modern controller with access to a computer network.

Most units have emergency fan operation until troubleshooting.

The main part of precision air conditioners EMERSON, LIEBERT HIROSS has wide monitoring capabilities and high universality due to several connection options at objects of completely different configurations.

BLUE BOX

Another Italian company BLUE BOX has established itself in the Russian market as a competitive manufacturer of precision air conditioners and other industrial cooling systems.

High-precision equipment is available in monoblock and separate versions, with air, water and mixed types of air coolers, as well as with built-in and remote condensers with water or air cooling. The power of precision BLUE BOX air conditioners varies from 6.4 to 220 kW.

The main parameters of the air in the room are supported with maximum accuracy to tenths of degrees and percent. Compactness is compatible with excellent performance and energy efficiency. The latest technology in the device of the fan and compressor allows you to produce units with minimal noise and air consumption.

BLUE BOX company produces precision air conditioners that work in all possible modes. Powerful shut-off valves and automatic safety systems prevent serious accidents. All devices operate on modern brands of freon that do not contain chlorine.

In order to correctly select the necessary model of a precision device, first of all, attention is paid to the air distribution system, the presence of the required operating modes, the accuracy of maintaining the parameters of the air environment and the operating temperature range for winter and summer.

Only a specialist will be able to fully calculate the power calculation and the necessary modification.