Cooling in the refrigeration machine occurs due to heat absorption during boiling of a liquid (freon) - a gaseous substance, which is not only the main functional element, but also part of the lubricant for the compressor along with oil.

It has no color, odor and is practically incapable of ignition, except for its direct contact with an open flame at a temperature of at least 900 ° C.

In order for a continuous cycle of refrigerant conversions (evaporation and condensation) to take place in the refrigeration unit, it is important to maintain a normal pressure in the system, due to which the permissible boiling point of the refrigerant will remain.

The boiling temperature of freon in the air conditioner is completely not equal to the usual indicators, at which the same water boils. In this case, it depends on the ambient pressure. The higher it is, the higher its performance, and vice versa, the lower the pressure, the lower its parameters. But they always have low values.

Different types of freons, characterized by physical properties and chemical composition, have different boiling points in the air conditioner under the remaining identical conditions. In refrigeration units, R-22, R-134a, R-407, R-410a refrigerants are most often used. The latter is considered the safest, as it does not pose a threat to the environment and humans. But its use in the air conditioner increases the price of the device.

The table below shows the boiling points of various types of freons in air conditioners - this is part of the table that installers use when refueling or refueling refrigerators. This is a kind of replacement for the line of the dependence of the boiling temperature on the pressure used in production or in service centers. The indicated values of normal temperature imply a standard atmospheric pressure of 0.1 MPa.

| Type of freon | Normal boiling point, ° C | Critical pressure, MPa | Critical boiling point, ° C |

| R-22 | -40,85 | 4,986 | 96,13 |

| R-410a | -51,53 | 4,926 | 72,13 |

| R-134a | -26,5 | 4,06 | 101,5 |

| R-407 | -43,8 | 4,63 | 86,0 |

Excessive heating of the freon can cause the release of substances hazardous to human health and vacuum in the evaporator.

Freon leak in the air conditioner

For an air conditioner, the leakage of freon is 4–7% of the total mass per year. Replenishment of losses on average is required once every one and a half or two years. If the interblock lines are mounted poorly, then through the poorly made rolling joints, the refrigerant leaves in larger quantities. Then we can talk about the injection of freon into the air conditioner in full or about the occurrence of a preliminary need to make up for losses.

When ignoring the problem, the device gradually begins to work within its capabilities, as a result of which the compressor breaks down, which simply ceases to be lubricated.

How to detect a leak

It is easy for a specialist to determine if there is a leak of freon from the air conditioner, but the user himself must also know some signs of loss of the main working substance. Should alert:

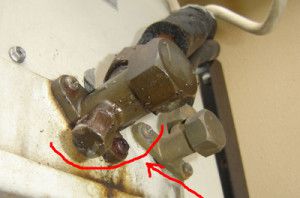

- noticeable frost or ice appear at the joints of the cold track and the valves of the outdoor module;

- cooling quality is greatly reduced;

- when you turn on the split system, it smells of burning;

- under the taps you can see smudges of oil - it gives an unpleasant smell;

- compressor thermal insulation darkens;

- the device switches off and error codes are displayed.

If any signs of freon leakage from the air conditioner are detected, immediately disconnect the device from the power supply and call the wizard.

A specialist through a manometer station will connect a nitrogen cylinder, block the ports and start overpressure in the system.It should immediately soap the pipes and suspected leak points. If there was a whistle, and in some place the soapy solution bubbled, then there is a hole through which the gas escapes. This determines the leakage of freon from the air conditioner, after which troubleshooting begins.

Instead of a soap solution, you can use a special concentrated liquid, which is driven into the circuit, and then the possible places of loss of refrigerant are illuminated with an ultraviolet light device.

Are there any other ways to determine the leakage of freon from a domestic air conditioner? For one of them you will need a special device - an electronic leak detector, which is equipped with a flexible probe with a sensitive sensor - it allows you to get to the most difficult places.

An insufficient amount of freon in the start-stop air conditioner can also be determined using a thermometer, which is brought to the air leaving the fan. If the indicators do not exceed the established standards of 5-8 ° C, then gas replenishment is not necessary.

If the cause of the loss is the leakage of interblock connections, the master will begin to solder the pipes and then refuel the device with a working substance.

Refueling and refueling the air conditioner with freon

How is freon air conditioning refueling, and how does it differ from refueling?

Refueling is a partial replenishment of the lost refrigerant volume. It may be needed in case of leakage or during preventive refueling. It is also carried out by increasing the route during installation. On average, the factory volume of injected freon is designed for 5 meters of the route. If there is an increase in its length, then it is necessary to refuel the air conditioner with freon at the rate of 30 g per meter of the line.

For household air conditioners with R-22 freon and the like, a refueling method is used, and for systems with R-410a freon, only the full refueling method is used. This gas consists of a mixture of chemicals with varying degrees of volatility, which evaporate completely unevenly, therefore, the composition of the remaining substance varies greatly.

Full refueling is the replenishment of the entire volume of gas in the refrigeration unit. It is necessary when filling household air conditioners with freon after moving, when all the refrigerant was previously lowered, or when replenishing the volume of refrigerant having a complex component composition.

Release of freon from the air conditioner

Before pumping freon into the air conditioner at full charge, the remaining gas must be released from it. How to merge freon from the air conditioner, and what tools will be needed for this?

Some masters do not see anything wrong with just loosening the nuts on the outdoor unit and bleeding everything into the atmosphere, considering the small amount of refrigerant safe for the environment. In its pure form, it is actually harmless, but you should not do so. For its release from the air conditioner, it is necessary to have a Freon collection station, which crashes into the air conditioning system using a special fitting and pumps out all the gas from it.

Next, they evacuate, and only after that they connect the cylinder with freon and pump it into the air conditioner at the required rate.

How much freon is needed

Different refrigeration systems contain different amounts of refrigerant. How much freon can be in the air conditioner depends on the cooling capacity of the unit. On average, its volume is in standard splits from 700-800 grams, and in powerful installations of commercial or industrial use more than a kilogram.

The required volume is indicated by the manufacturer on the nameplate, which is a metal plate on the inner case of the split. It helps to determine how much freon in the air conditioner should be. Using a manometer, the master determines the pressure in the cooling case and looks at this plate.

Ideally, filling home air conditioners with freon should take place in small portions so that more gas does not get into the system, since its oversupply leads to inefficient operation - it does not have time to go through a complete cycle of transformation from one state to another.

How to refuel an air conditioner

The air conditioner can be refilled in several ways, but the simplest and often applicable are:

- filling by weight (by weight) - you need expensive scales to weigh the cylinder with the refrigerant;

- pressure filling - at values below 3-3.5 atm, gas replenishment is required;

- current - need current clamps superimposed on the phase of the power wire of a working external unit.

There are two more ways: refueling by subcooling and by overheating. But in reality, they are used only when checking industrial compressor and condenser units, since in household splits there is no device that regulates the consumption of freon. Its role is played by the capillary tube.

If, after full or partial refueling of the air conditioner, its operation does not equalize, then equipment should be diagnosed to detect other system malfunctions.

Only experienced installers know all the safe ways to drain freon in an air conditioner and how to make up for its lack. Do not try to carry out such actions yourself, which can lead to burns of the skin or eyes, as well as completely disable the refrigeration machine.