Any air conditioner is a complex electronic device that consists of many interconnected parts. Modern chillers are created using the latest technology, but this does not prevent the failure of one or another important component, which makes further work impossible.

Timely service and repair of air conditioners helps to eliminate many malfunctions until the moment the device finally fails. As a rule, the owner of such equipment should from time to time order professional cleaning and diagnostics of the system, after which the climatologist informs the user about all possible and existing problems.

Repair of the air conditioner can be carried out both on site and in the conditions of service. It all depends on the complexity of the breakdown, as well as the owner’s willingness to pay for dismantling and subsequent installation of equipment.

Damage to the fan, compressor and air conditioning control board

What are the most common malfunctions of air conditioners?

Conventionally, all breakdowns can be divided into malfunctions of the components of the refrigeration circuit and failures in the electronics or failure of the electrical components of the system. Most often, users of the same split systems encounter breakdowns of the board, fan, compressor or leakage of the heat exchanger of the outdoor unit. This is due to the fact that the main load is precisely on these parts, so their wear, especially when the operating conditions are not observed, is inevitable.

Fan

What can happen to an air conditioner fan and what kind of repair is carried out in certain situations?

Some malfunctions are indicated by error codes displayed on the display panel of the indoor unit. If the fan “flew”, then most likely the system will turn on for a few seconds, and then turn off again. There are several reasons:

- defective fan blades;

- defective fan motor;

- defective fan motor capacitor.

In all three cases, the solution to the problem will be the replacement of the failed part.

The service worker first of all checks the resistance of the windings with a tester, which are different for different models of chillers and are given in the manuals. If the suspicion is confirmed, then proceed to repair the air conditioning fan.

Fan impeller replacement:

- Remove the front protective grille;

- Unscrew the fan fastening nut (left-hand thread);

- Remove the impeller from the motor pulley;

- Put a new impeller on the pulley;

- Collect parts in the reverse order.

Fan motor replacement:

- The system is de-energized and the protective front grille is removed;

- Unscrew and remove the fan mounting nut (left-hand thread);

- Disconnect all electrical connections to the fan motor;

- Unscrew the motor itself from the body and remove it;

- Put on a new spare part;

- Collect and fix parts in the reverse order.

Replacing the starting capacitor of the fan motor:

- Completely de-energize the system;

- Dismantle the case of the outdoor unit;

- Unscrew the fixing bracket of the capacitor;

- Disconnect all wires from it;

- Replace with a new starting capacitor;

- Collect and fix parts in the reverse order.

Typically, repairing an air conditioner fan takes no more than an hour.How much such repair costs depends on the urgency of the work, their volume, air conditioning capacity, the amount of materials and spare parts used.

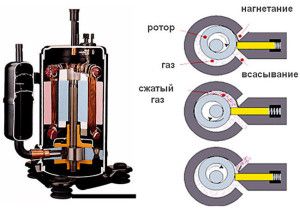

Compressor

What are the main malfunctions of the air conditioning compressor encountered, and what repairs are carried out in a particular case?

Most often, a compressor malfunction is indicated by the incorrect operation of the device, namely:

- it does not turn on at all or a delay of inclusion for several minutes;

- it does not turn on and at the same time emits a corresponding buzz;

- frequent change of start and stop cycles.

The reasons may be incorrect phase switching, start-up capacitor malfunction, compressor crankcase filling with liquid freon, failure of the expansion valve or four-way valve. This is not a complete list of issues. But most of them do not require replacement of the compressor itself. It is enough to eliminate the cause and the device is functioning normally.

If there is a phase imbalance, then most likely the load on the network is not distributed correctly. An air conditioner with a three-phase connection cannot be installed on a single-phase network and vice versa. The current is checked usually with clamp mites on each phase and the load is redistributed. You may need to bulkhead the electrical panel.

If liquid refrigerant fills the crankcase, then first of all it is necessary to bleed off the existing freon, evacuate the system, after which the circuit is charged, since it is the lack of refrigerant that causes such problems. It may be necessary to reconfigure the condensation pressure regulator.

If there is a problem with the four-way valve, it’s worth remembering that replacing it will cost a little less than repairing an air conditioning compressor, so first check the health of the electrical circuit and if there is enough freon in the circuit. When the problem persists (blowing with warm air in any mode), then this part can be evaporated, but this is done only if there is no need for subsequent heating.

It may be necessary to replace the oil with a better one or try to supply power for a short time to the four-way valve. In an extreme case, it is replaced.

When a complete compressor replacement is required, do this in the following sequence:

- Freon is collected from the system by a manometric station.

- Disconnect the device.

- Dismantle the external unit.

- Dismantle its body.

- Disconnect the tubes and electrical wires from the compressor.

- Remove the compressor from the vibration dampers.

- Install a new one on vibration dampers.

- Fasten and solder all the tubes back.

- Connect the wires.

- Assemble the case and mount the unit back.

- Connect tubes and wires.

- Evacuate the circuit and refill it again.

- Turn on the device for checking.

When repairing an air conditioning compressor, pipes are brazed with nitrogen.

Electronic control board

How is the malfunction of the control board manifested and in what ways can it be fixed?

If all the LEDs blink on the indoor unit, and the split system does not turn on at the same time, then most likely a failure has occurred in the software settings of the control board. This is eliminated by reprogramming it in the service center using codes, information about which is available only to employees of this center.

The control board could burn out during power surges (inverter systems are sensitive to this) or during a short circuit, so in this case it will need to be repaired - broken chips are soldered and soldered new ones, the triacs are replaced with more powerful ones, the buffer chip is checked.

Manufacturers equip control boards with solid-state switches, which are responsible for the rotation of the fan, so failures in its operation may indicate a malfunction of this element. Before proceeding with the repair, it is necessary to measure the resistance of the part. If it is closer to zero, then the broken chip is evaporated.

Malfunctions of the compressor, temperature and motion sensors can also be signs of a malfunction of the control board.

When a burnt microcircuit is visible to the naked eye, there is no need to take resistance measurements. They immediately begin repairing the air conditioning control board - replacing the triac.

Sometimes during installation, installers make mistakes in interconnects, which also leads to a failure or burnout of the board. Most often, diode bridges, a transformer or a voltage stabilizer are burned first. In such cases, it is more advisable to replace the failed part. It is impossible to repair the air conditioner board, if it burned out completely, then it is replaced.

Replacing the control board:

- Turn off the power;

- Dismantle the case or remove the top cover of the unit;

- They pull out the board from the grooves by unscrewing the fixing screws and disconnecting all the wires and connectors;

- Replace with a new one and assemble the block in the reverse order.

It is better to contact a service center right away, since repairing a board near an air conditioning system is an expensive process, and if you handle the device elements inaccurately, additional waste may occur.

Air conditioner outdoor unit heat exchanger malfunction

Split systems have another problem - freon leakage through the heat exchanger of the outdoor unit. In cars filled with R-22 freon, they are looking for it with the help of a leak detector; units operating on the modern R-410a are soaped and see where foaming will occur.

There are two ways to eliminate leaks through the heat exchanger of the outdoor unit:

- Soldering. The burner heats the leak on the radiator tube and solders it. Do this very carefully, as the tubes are very thin and easy to melt.

- Replacement. Turn off the external unit and disassemble its body. Cut out a pipe cutter or solder an old heat exchanger and replace it with a new one, soldered with nitrogen. Assemble the module back, connect the electrical connections, tubes and vacuum the system. Refuel and run again to check the health.

When replacing a condenser heat exchanger, air conditioning systems can be repaired on site without additional dismantling.

What determines the cost of repairing an air conditioner and an approximate estimate

How much does air conditioning repair cost and what does pricing depend on?

Here, several factors influence:

- Complexity of work. It is much easier, for example, to repair a fan impeller than a compressor.

- Availability of normal access to the device.

- Cost of consumables and spare parts. If the master has to change the heat exchanger, and not solder it, then the cost of the provided service will rise.

- Urgency. If you do not want to wait until the specialist is free, you can order an urgent repair of the air conditioner, but this doubles the cost.

- Night call. Some facilities cannot be repaired in the daytime, and the nightly rate, as a rule, has different rates.

To determine the final cost of repairing the air conditioning system, the master draws up an estimate indicating the services provided and the amount of materials used. There may be indicated additional services that were provided during the repair.

For clarity, an approximate estimate of the repair of the air conditioner is given below.

| Service | Used materials and equipment | amount | Price |

| Departure of the master | 1 | 500 r | |

| Diagnostics of a wall split system 2.5 kW | 1 | 1000 r | |

| Path soldering (defect correction) | Solder | 1 | 800 r |

| Freon circuit filling | Freon R-410a | 600 g | 2000 r |

| Bracket Mount Troubleshooting | 1 | 500 r |

Total: 4 thousand 800 rubles 00 kopecks.

All prices in the estimates for the repair and maintenance of the air conditioner are given conditionally. They can vary significantly from company to company.

Recommended Reading

For a deeper study of the issue, it is recommended that you read the books on air conditioning repair by the following authors:

- Bogoslovsky V.N. 1985. Air conditioning and refrigeration.

- Burtsev S.I., Blinov A.V. 2005. Installation, operation and maintenance of ventilation and air conditioning systems.

- L. Korch 2004. Air conditioners.

- Collective authorship. 2010. A training book on the repair of modern air conditioners.

- Kashkarov A.P. 2011. Installation, repair and maintenance of air conditioners.