Refrigerant R12 in the West is banned for refrigeration, so its production is limited and the price continues to rise. The substance destroys the ozone layer, so applying it is becoming increasingly unprofitable. The question is what can replace R-12 freon and how much is it possible. On the other hand, new types of freons impose higher requirements for equipment - the quality of pipes, soldering. This is due to the fact that the pressure in the system rises when a modern type of coolant is used, and outdated systems may not withstand leakage. It is necessary to replace the liquid with one in which the physical and chemical characteristics are similar.

R12 refrigerant specifications

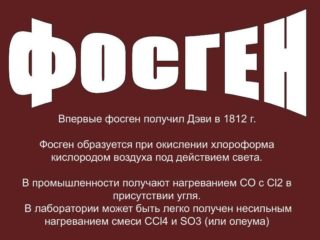

It is a colorless gas with a specific odor. Safe to use, does not explode. It decomposes at temperatures over 330 degrees. In this case, gas evolution is possible - phosgene. With a concentration in the room of more than 30%, suffocation develops.

It is a colorless gas with a specific odor. Safe to use, does not explode. It decomposes at temperatures over 330 degrees. In this case, gas evolution is possible - phosgene. With a concentration in the room of more than 30%, suffocation develops.

It does not chemically bind to any metals, therefore it does not damage parts of air conditioners from the inside. Leaks occur due to increased fluidity, in which the substance penetrates through the smallest gaps and inconsistencies. It is able to seep through natural pores in cast iron. This property has a downside: oil, which is added to the refrigerant liquid, penetrates between all parts due to fluidity, reducing the coefficient of friction and prolonging the life of the product.

The boiling point of R12 freon is 29.74 degrees.

When to change the refrigerant

Leaks in air conditioners always occur, no matter how tight the construction is. The question is how much and what needs to be added if the substance evaporates or flows out. R12 fluid has a great advantage - it consists only of difluorodichloromethane molecules. If the substance evaporates, then only it needs to be added. There are refrigerants that vaporize any one chemical element in the composition. We have to calculate how much and what to refuel in percentage terms.

If the air conditioner starts to junk, it does not produce the amount of cold that is declared, then it’s time to refuel. But at reasonable prices for R12, it’s worth considering whether it is easier to bleed it and buy a R12 freon substitute. There are more than a hundred of them, so there is a choice. It remains to find out which is better, cheaper, evaporates less, gives more cold.

Analogs and substitutes for R12 freon

In refrigeration equipment operating on R12 freon, only mineral solvent is used. Chlorine is soluble only in this form of oil. The substitute will contain either a small amount of chlorine, or flammable gases that can also be dissolved in the mineral must be used. Here you need to decide which is more important:

- safety;

- practicality and well-functioning device.

If, for example, propane is poured into the refrigerator instead of R12, then it works. But the presence of more than 1 kg of such a substance makes the device an explosive device. Under certain conditions, it can ignite:

- improperly mixed substances;

- pouring more than necessary;

- heating and expanding the volume of the mixture.

This prospect is not happy, so you need to look further. Chlorinated R22 is not suitable, as its pressure is higher. Not one solution was found. In R22, various substances began to be added to reduce the pressure of the gas and not interfere with its dissolution. All analogues of R12 freon are distinguished by additives to R22.

This prospect is not happy, so you need to look further. Chlorinated R22 is not suitable, as its pressure is higher. Not one solution was found. In R22, various substances began to be added to reduce the pressure of the gas and not interfere with its dissolution. All analogues of R12 freon are distinguished by additives to R22.

Here are some of them:

- R21 is used only in Russia. The boiling point is higher: +8.7 degrees.During operation, the compressor may stop over time and damage the valve.

- R142B is an inexpensive supplement. For different equipment, the optimal ratio of R22 and R142B is selected. If there are more connecting nodes, then 22 will evaporate faster and should be larger in percentage terms. If there are fewer potential leak points, then the percentage of substances will be different - R22 will need less. To refuel such a mixture in an air conditioner, no more than 80% of the amount of R12 is needed.

- R406A - the optimal ratio of price and quality, as well as the good operation of equipment on such a mixture. Substances under the code 22 and 142B are mixed in the proportions of 55% and 41%, respectively.

- R401 and 409 are the most expensive, but good substitutes. Their cost is comparable with the R12 freon itself. It makes no sense to overpay for the environment - the regulatory authorities in Russia do not go to apartments and do not check which refrigerant is circulating in the system.

Any product analogue will still not be able to compete with the original, so the owner of the air conditioner must decide what to fill in with R12 instead of Freon.

How to choose mineral oil for freon

R12 Freon Oil is essential. It provides the work of rubbing parts. Reducing friction increases the life of the compressor, the replacement of which is an expensive pleasure. Lubricants remove part of the heat as the oil heats up longer. Of great importance is the degree of miscibility (solubility) of freon and oil.

For freon R12, only mineral oil-based lubricants — naphthenic and paraffinic — are used. When choosing an oil, it is important to know that the pour point and fluidity were lower than the boiling point of the refrigerant.

When working in refrigeration equipment, the purpose of lubrication is to create a durable film on friction parts. When the temperature rises above the set value, the surface tension of the oil decreases, and the viscosity increases, which prevents the normal dissolution of the refrigerant and its circulation.

When working in refrigeration equipment, the purpose of lubrication is to create a durable film on friction parts. When the temperature rises above the set value, the surface tension of the oil decreases, and the viscosity increases, which prevents the normal dissolution of the refrigerant and its circulation.

Minerals are more sensitive to temperatures. If the equipment overheats for any reason, the mixing process is disrupted, acidity increases and the oil darkens. After repair, drain the fluid and pump a new one. An increase in acidity leads to the burning of the motor winding.

Lubricants for refueling refrigeration equipment are bought from reliable suppliers, since poor-quality composition and the presence of water in it leads to chemical processes inside the air conditioner, which negatively affects its operation.

Refueling is carried out with all the necessary tools, namely, a device for evacuating the system. The presence of air residues in the system before refueling affects the stability of the chemical composition of the freon-oil mixture.

Do not mix mineral and synthetic oil.

The brand manufacturer of lubricants Mobil Gargoyle Arctic Oil 300 or 155 offers high-quality components for air conditioners. Due to dewaxing (purification), the substance has good fluidity even at the lowest temperatures. Turbidity of the oil is rare - at very high temperatures. The grease is free of moisture and sealed in its original packaging. During operation, care should be taken to prevent water from entering the oil.

When working with original oils, no special precautions are required. The substance does not adversely affect human health.