Pressure gauges for refueling air conditioners are measuring instruments that monitor the pressure in a split system. They are used to evacuate the route so that moisture vapor is completely removed before refueling. Each master who is professionally engaged in cooling systems has such a device, the device of which is simple, but requires an understanding of the principles of operation. Since different types of refrigerants have different potential pressures, they use the appropriate gauge manifolds to charge air conditioners.

What is a gauge station (collector)

The refrigerant pressure in the air conditioning system is the most important parameter for the operation of a split system. If the pressure in the high or low circuit is increased, this leads to increased operation of the compressor and its rapid failure. At low pressure, the equipment operates poorly and does not fully perform its functions. Manometer manifolds or stations are used to measure the pressure level of Freon. Applied devices for refueling climate systems with freon and oil.

Pressure gauge station with hoses for refueling air conditioners are used in automobile air cooling systems. In car services, stationary devices with elongated hoses are used to control pressure. Service technicians for wall split systems carry portable compact devices.

Collectors are used to repair refrigerators. The modification of the devices is somewhat different, but the principle of operation and the ultimate goal are the same: to check the refrigerant pressure and, in case of shortage, to refuel.

What are gauge stations

There are two types of collectors:

- Having one tap, 2 hoses and a blue pressure gauge. In other words, monovent. For the repair of refrigerators such a device is enough. It measures the level of absorption of coolant. The connection between the hoses is isolated by a valve.

- Having 2 taps, 2 manometers and three hoses. These are two-valve devices that are capable of measuring pressure in two directions. A red manometer determines the discharge pressure, blue - suction. This equipment is used both for refueling the freeways of air conditioners and refrigeration equipment, and for evacuating the pipe system after utilizing the refrigerant. Air into the system during operation of the connected device stops flowing.

There are also four-valve and six-valve ones, but for servicing split systems a single or two-valve device is enough.

Subdivided by accuracy class from 0.2 to 4.0. The lower the ratio, the more accurate the equipment. For vibration service, vibration-resistant models of pressure gauges are used.

In turn, reference instruments are used to verify the correct operation of the pressure gauges. If there is any doubt that the gauge station is showing incorrect values, it must be checked with a different gauge.

Depending on the purpose, the devices are divided into several types, but when working with climatic equipment, the spring principle of measuring pressure in the pipeline is used. The spring inside is deformed by pressure. The degree of deformation is a measure of determination on a gauge screen, which can be liquid crystal or analog.

Depending on the purpose, the devices are divided into several types, but when working with climatic equipment, the spring principle of measuring pressure in the pipeline is used. The spring inside is deformed by pressure. The degree of deformation is a measure of determination on a gauge screen, which can be liquid crystal or analog.

For each type of freon, a measuring device suitable for pressure level is used.

The fact is that the potential pressure in a system filled with more environmentally friendly fluids is higher than obsolete forbidden freons. Therefore, in order not to disable the manometer, it is selected according to the type of freon in the system.

Pressure Equipment Manufacturers

The best are considered manometric stations manufactured in the USA and Japan. Mastercool brand of equipment is a recognized leader that produces spare parts for measuring instruments. The devices are reliable and durable, work for years without the need for repair. Depending on the design and source materials, they are selected at a price.

The second manufacturer of measuring instruments is China. Many craftsmen prefer Chinese products for their cheapness. Buying cheap devices for everyday use, you can make a mistake and purchase a fake that will not work until the end of the warranty period. The device may not show the correct values - because of this, customers will have problems with the operation of the climate equipment, which will entail complaints and proceedings.

Among the Chinese models there are really good manufacturers, so you need to know who to buy a professional device for work from.

Domestic brand EKV is suitable in price and quality for Russian split systems, but for high-tech equipment made in Japan, manometers of higher accuracy should be chosen.

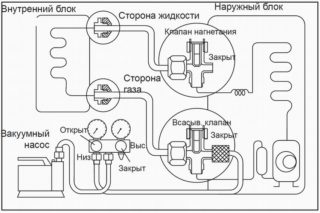

How to use gauge station to charge air conditioner

The first time it is recommended to see how a specialist measures pressure with a manometer, and then fills the system with freon. Without experience, you should not undertake such a job.

When refueling, you must follow the rules:

When refueling, you must follow the rules:

- if at least 30 - 50% of the refrigerant remains in the system, evacuation can be omitted, if less than the specified amount - the procedure is carried out completely - the system is first drained, then evacuated, then filled;

- after refueling, it is checked for leaks and tested with nitrogen (an ordinary citizen may not have a device for this purpose);

- if you need to add oil, then it is calculated by weight - no more and no less so as not to change the chemical characteristics of the refrigerant;

- if you check the amount of liquid charged by temperature, you need to have a special device that is expensive enough to buy it at once;

- a single-valve suction pressure gauge is used only when the compressor is on.

Work Stages:

- Using a cylinder of liquid nitrogen, drain the system.

- Vacuum pumps remove residual moisture and nitrogen.

- The necessary amount of freon will be filled into special scales through a manometric station (how many and which brands are written in the instructions).

- Turn on and wait until the fluid is pumped into the line.

The refueling procedure without special equipment can render the climate equipment unusable, therefore, in order to avoid costly repairs, it is recommended to invite air conditioning service specialists.

To check the filter in the automobile air conditioner, the degree of clogging of the evaporator, compressor operation, a metrological station is used and a high-pressure line is connected. For simple refueling, connecting a high pressure station is optional.