In the uninterrupted operation of the air conditioner, the main role is played by its installation. Poor installation of freon connecting lines can cause low productivity of the device, and poor-quality drainage hose leads to an unpleasant smell of stagnant water in the apartment and its entry into the room.

Copper pipes for air conditioning

For freon air conditioning mains, copper pipes are used that comply with GOST standards for diameter size if the production is made by a domestic company, and DINy or ISO standards if it is imported material.

GOST requirements

As a rule, in such normative documents the main parameters and dimensions are indicated, to which the goods must comply, namely:

- pipe wall thickness;

- diameter of pipes and fittings;

- product weight;

- copper content in percentage terms;

- mode of production.

In Russia, according to GOST standards, copper pipes for air conditioners and refrigerators must comply with the following parameters:

- annealed copper products have a diameter of not more than 7/8, and the wall thickness does not exceed 0.65 mm;

- articles of unannealed copper have a diameter of more than 7/8, and the wall thickness does not exceed 0, 85 mm.

Copper pipes are delivered in bays with plugged ends or finished pieces up to 4 meters in length. Bays can also have different sizes - from a couple to several tens of meters.

Each manufacturer must have a certificate for a copper pipe for air conditioners, which confirms its proper technical characteristics and compliance with sanitary and hygienic requirements.

Any company that provides services for the installation of HVAC equipment is required to provide a quality certificate for both the copper pipe for air conditioners and other materials used in the installation of cooling devices.

This table shows some parameters that finished products must comply with according to GOST of copper pipes for air conditioners.

| Nominal Diameter Inches | Thickness (mm) | Pipe Weight (kg / m) |

| 1/2 | 1,0 | 0,42 |

| 3/4 | 1,15 | 0,68 |

| 1 | 1,25 | 0,97 |

| 1-1/2 | 1,5 | 1,7 |

| 2 | 1,75 | 2,6 |

| 2-1/2 | 2,0 | 3,7 |

| 3 | 2,25 | 5,0 |

For copper tubular products manufactured according to foreign standards, these parameters may vary slightly.

The manufacturer of climatic equipment usually indicates in the instructions the required pipe size, since, on the one hand, the diameter must be large to reduce pressure losses, and on the other hand, it will be necessary to ensure the return of oil, which imposes restrictions on the maximum value.

Benefits

Why is this metal used for the manufacture of a freon binder? The fact is that copper is a structural material that exhibits ideal properties for the installation of air conditioning communications. It:

- has a high degree of corrosion resistance, which eliminates the change in cross section;

- It has high strength with respect to the effects of chemically active substances (refrigerant and oils);

- resistant to temperature fluctuations in the range from -150 ° C to + 150 ° C;

- Immune to UV and heat radiation.

Products made of annealed copper are easily bent, with them flaring of air conditioning pipes does not cause any problems. It is difficult to perform such actions with untreated copper, therefore, for joining pipe elements between themselves, fittings are used - couplings and corners.

Installation

First, check the size of the pipe and cut the desired length, taking into account a small margin. Before cutting, be sure to straighten the product and install it in the cutter rollers so that the knife is perpendicular to it.

Cut the product with a pipe cutter.It is impossible to saw it, as roughness and roughness will remain.

Installation of a freon line requires accuracy and the availability of a set of installation tools.

Having directed the pipe end-down, a rimmer strips it of the burrs. If you leave any irregularities, a gas leak may occur and the air conditioner will stop working.

Then they go on to expand the conditioning pipes by bending them with a pipe bender. The bend radius must be at least two diameters. Do not bend and unbend products more than 3 times. When tracing, sharp turns are avoided so as not to deform the edges and reduce the “working” section.

After the flaring of pipes at the air conditioner is completed, they go on to solder the elements of the pipeline among themselves. For refrigeration use silver and copper-phosphorus solder. Then they proceed to connecting the pipelines to the service taps of the indoor and outdoor units. Either adapters or welding are used here.

When the cooling line is connected to the nozzles of both modules, the tightness of the system is determined. For this, nitrogen and an electronic leak detector are needed. Then a vacuum is created in it and freon is pumped.

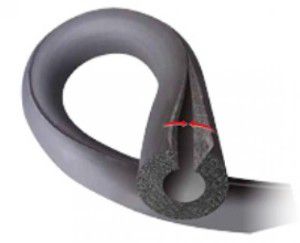

Copper pipe insulation

Do not forget about the insulation for copper pipes of air conditioners, which serves as a heater and prevents condensation from forming. It is usually made of foamed polymer rubber having a very low specific gravity. The refrigerant piping is thermally insulated over its entire length simply by wearing insulation on top. Seams are glued with silicone sealant or wrapped with electrical tape.

Insulation for copper pipes of air conditioners is not worn on fittings and other difficult sections. It is advisable to minimize the number of seams in mechanical and thermal protection so that the performance of the device does not drop.

For copper pipes of air conditioners, high-quality insulation can withstand the temperature range from -30 ° C to + 80 ° C. It is easy to cut, pulls effortlessly on the pipeline and has high strength.

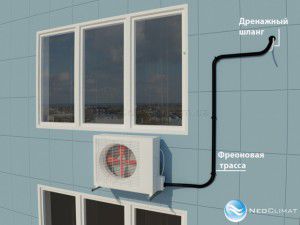

Air conditioning drain pipe

As already mentioned, to drain the condensate of the air conditioner, it is necessary to install a drainage pipeline, which is mainly made from a corrugated polypropylene or polystyrene tube on the outside. The discharge is organized in several ways:

- to the street;

- into the sewer;

- by gravity into a special container.

In order for the drainage pipe for the air conditioner to serve for a long time, and no rises or sagging on its surface, it is necessary to select a suitable throughput, and the laying slope should be no more than 1%. If this is not possible, use a drainage pump.

In the distribution system, drainage hoses are tried to provide maximum tightness during connection in order to prevent an increase in humidity inside the room, which makes the device work in an enhanced mode and significantly reduces energy efficiency.

Inside the room, the drainage pipes for the air conditioners are cleaned in a decorative box along with the rest of the communications. The box goes along the wall and goes out into the street, where the excess liquid will be drained from the system.

If the air conditioner will work in winter, then to heat the drainage hose, a heating cable of the appropriate power or an electric heater is installed, which does not allow moisture to escape from the pipe.

Installation work of air conditioners should only be carried out by masters with the appropriate education and experience, otherwise expensive equipment will fail or give out low performance.