For suburban areas, the problems of soil saturated with moisture are relevant. This adversely affects crop yields. But no less important is the need to protect the foundations of buildings and structures from groundwater. If you properly drain the site and correctly install the plastic drainage well, you can easily solve the problem of excess moisture in the area.

Types and arrangement of drainage wells

In the country, drainage wells are equipped with one or more containers. They vary in function and design.

In the country, drainage wells are equipped with one or more containers. They vary in function and design.

- Drainage tanks - collect water from the entire drainage system. Installation is carried out in the lowest part of the site. Sealed containers are often equipped with pumps. Water from the drainage tank is then diverted to the general sewer, or used for irrigation in the area.

- Viewing or inspection shafts - these structures are equipped with a hermetically welded bottom. They are used to monitor the operation of the drainage system and periodically clean it of sludge and debris. The distance between the observation shafts should be no more than 50 meters on straight sections. In addition, they are installed in places where pipes turn. Manholes are often made of drainage pipes.

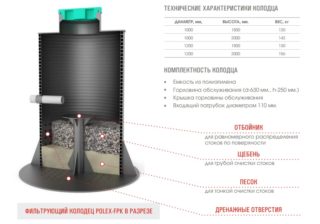

- Tanks without bottom are used as filter elements.

- Expansion tanks are installed to reduce pressure in the drainage system. Apply in regions with heavy rainfall.

- If there is a difficult terrain with large elevations at the summer cottage, it is rational to additionally install differential wells.

Tanks are made independently, or purchased finished products. Factory models are manufactured in a prefabricated or monolithic version. The prefabricated well includes the following elements:

Tanks are made independently, or purchased finished products. Factory models are manufactured in a prefabricated or monolithic version. The prefabricated well includes the following elements:

- bottom;

- mine;

- neck;

- Luke.

The outer surface of the container is smooth or corrugated. Corrugated models have high strength and reliability. The ring stiffness of the sump allows you to withstand severe loads created by the soil.

Production material

A traditional option for drainage wells are concrete structures. They are arranged independently, or from finished reinforced concrete parts. The main advantage should be called the possibility of descent into the tank and the implementation of cleaning. But serious disadvantages are the heavy weight of individual elements, as well as the complexity of transportation and installation.

Plastic models are becoming more widespread, especially for the device of summer cottage systems. They have a lot of advantages over other materials:

- Simple in construction and easy to install.

- They have holes for supplying pipes, which are equipped with rubber cuffs. This greatly increases the tightness of the structure.

- Lightweight and inexpensive.

- Transportation and installation of a drainage well made of plastic is not difficult. It does not require the use of construction equipment.

- The material is resistant to chemicals.

- Manufacturers produce a wide range of multifunctional components.

- The service life is quite long.

Plastic products are made from polyethylene (HDPE), polyvinyl chloride (PVC), polypropylene (PP). Smooth or corrugated plastic pipes with a diameter of 300 mm and more are often used for their manufacture.

The simplest designs are a regular foundation pit into which water enters. However, the walls of a makeshift well should be concreted.So it will last longer and more reliably.

The main criteria for choosing a drainage well

The dimensions of the well are selected depending on the area of the territory on which the drainage system is arranged. It is also worth considering the degree of humidity of the site.

The dimensions of the well are selected depending on the area of the territory on which the drainage system is arranged. It is also worth considering the degree of humidity of the site.

For inspection wells, pipes with a diameter of 300 mm or 400 mm are usually used, the catchment products are taken in a larger size. The height of the shaft is determined based on the depth of the drainage system. It is counted from the bottom of the outlet pipe. For arrangement in the lower part of the construction of the sump chamber, it is necessary to add 20-40 cm to the shaft length.

For drainage wells, which are planned to be equipped with a pump, the shaft diameter should be at least 50 cm. For its installation, it is worthwhile to provide a camera device from 50 cm to 100 cm high.

For ease of operation and maintenance, additional components made of plastic are available:

- bottoms;

- hatches;

- couplings for connecting pipes;

- check valves.

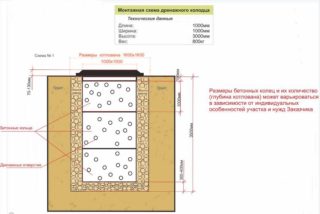

Reinforced concrete rings for drainage wells are selected from moisture-resistant concrete grades. The size of the elements depends on the purpose of the tank. They are produced with a diameter of 70-200 cm and a height of 10-100 cm. For cottage wells, the circumference of 70-150 cm is suitable. The width of the ring is selected from 50 cm to 60 cm.

Preparatory work

The preparatory work before installing the drainage well on the site consists of digging trenches and assembling the structure from the pipes.

When installing the system, it is first of all necessary to determine the installation sites of the drainage structures. Installation technology depends on the type of tank. Under rotary, inspection and catchment structures, concreting of the site is preliminarily performed. For filter containers, a base is prepared from a layer of sand and gravel. It is advisable to lay a geotextile layer under the construction.

Installation Steps

On the prepared basis, the assembly of the structure is performed:

On the prepared basis, the assembly of the structure is performed:

- The pipe is cut at a given length - the height of the shaft.

- The bottom is attached to the bottom.

- In the walls of the mine, holes are cut for the entrance of the drainage pipes.

- The connection of pipes and containers is performed using couplings.

- If required, a check valve is mounted on the end of the inlet pipe.

Viewing shafts are installed in the drainage ditch, collect and fill the structure with a layer of rubble.

Similarly, the assembly and installation of the storage tank. They can be performed in vertical and horizontal position. In addition, the arrangement of a drainage well may include the installation of a pump and the connection of pipes that divert water to a common sewer.

The final stage of installing a drainage well made of plastic will be the laying of the hatch.

Installation of a concrete sump

Concrete structures are arranged to a depth of more than 200 cm. Installation is carried out in two ways. In the first embodiment, soil is gradually removed from under the laid ring. Under its own weight, the element lowers to the required depth. In the second case, the rings are installed in a previously dug pit.

- Pipes are dug from the reservoir.

- Holes make their way into concrete walls.

- Rubber seals are put on the ends of the pipes.

- The pipes are fixed in the holes and sealed.

At the end, the structure is sprinkled with rubble. Upstairs lay a hatch or ceiling.

The cost of installing a drainage well depends on the material, tank size, tank design, and manufacturer. Correctly selected option and competent arrangement of the system will guarantee a long operation. Compliance with the installation technology will avoid many problems in the maintenance of the system.