Soundproofing a sewer riser is an urgent need, especially if the apartment is in an old house. Plastic and cast-iron pipes make a lot of sounds that disturb the peace of residents.

Causes of noise in sewer pipes in an apartment

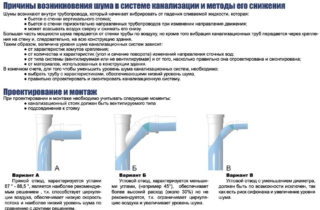

Noise in the toilet or bathroom occurs when the vibrations of the sewer pipes of an apartment building. They can hit walls and floors, which also creates unpleasant sounds. The main factors affecting the appearance of hum and knocking:

Noise in the toilet or bathroom occurs when the vibrations of the sewer pipes of an apartment building. They can hit walls and floors, which also creates unpleasant sounds. The main factors affecting the appearance of hum and knocking:

- mobility of the building structure;

- discharge of fecal water;

- wrong material choice - thin-walled plastic pipes rustle more strongly than cast-iron or thick-walled products;

- resonance in the system connecting the riser and floors;

- insufficient fastening of sewer pipes to building structures;

- excessive ventilation of the drain.

Some reasons for the appearance of noise are characteristic not only for the equipment of sanitary units, but also for heating pipes.

To what extent isolate

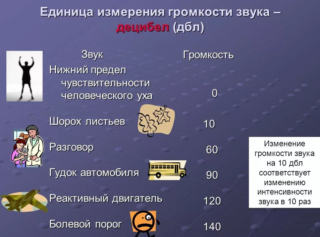

When choosing a sound-absorbing material, it is important to consider its cost per square meter and the effectiveness of eliminating hum. In order not to spend extra money and to isolate the riser as much as possible, it is important to find out how much it is necessary to damp the fluctuations of the drain.

When choosing a sound-absorbing material, it is important to consider its cost per square meter and the effectiveness of eliminating hum. In order not to spend extra money and to isolate the riser as much as possible, it is important to find out how much it is necessary to damp the fluctuations of the drain.

The intensity of sound waves of different ranges:

- audibility threshold - 0 dB;

- whisper - from 20 d 30 dB;

- apartment in a quiet area - 50-60 dB;

- metalworking shop - from 70 to 80 dB;

- rock concert - 90-100 dB;

- pain threshold - 130 dB.

With noise isolation of the sewer riser in the apartment, the selected material should attenuate the sound by 20-30 dB. The standard value of the degree of sound absorption in residential premises is 26 dB.

Necessary tools and materials

For soundproofing the riser, you will need to prepare the tools:

- dowel;

- ruler;

- square;

- pencil;

- moisture resistant drywall with a thickness of 13 mm;

- 3 floor-to-ceiling profiles.

The most common materials used for soundproofing sewer pipes are foamed polyethylene and rolled products. When buying, it is important to focus on the level of noise absorption indicated in the characteristics of the product. On the label write the number of decibels that it is able to absorb.

Choosing sound insulation, it is worth taking a closer look at its outer layer. The more rigid it turns out, the longer the protection of the pipeline will last, without losing its original properties. Foam is not suitable for sound absorption because it is not able to eliminate noise.

To create reliable sound insulation of the sewer pipe, it is enough to contact a car shop. Here you can purchase high-quality vibration isolation. The best option is a modern 3 mm thick Vibroplast material. They wrap plastic pipes, joints and spans. The insulation adheres well to the surface of the polypropylene riser, even without a hair dryer. It is better to stack the sheets not end-to-end, but overlap, without leaving gaps.

An expensive and effective way to soundproof a riser is to use the K Fonik material. It consists of two layers of rubber and has a sound absorption index of 26 dB.

The main methods of soundproofing sewage

The best pipe insulation is the absorption of various sounds by the product itself. Models are sold that, in addition to plastic, contain mineral powder (microcalcite, consisting of marble powder or flour). Sound absorbing pipes have thick walls and are longitudinally marked with red and green stripes.Their outer layer is made of polyvinyl chloride. Service life exceeds 20 years.

Installation of soundproof pipes involves several stages:

- cut a piece of gutter in size;

- to carry out installation of sealing rings;

- clean the outer and inner surfaces of dirt;

- apply silicone to the end;

- insert the pipe into the socket until it stops, and then push it out 10 mm from it;

- fix the drain by attaching it to the wall.

The disadvantage of noise absorbing pipes is their high cost. However, soundproofing of sewer risers made of cast iron and plastic is also possible. It is better to separate them from the floors with a plastic cup. There must be mounting clamps between the pipe and the walls. They can be replaced with an insert made of microporous rubber or a car camera.

Pipe insulation in straight sections is made of polyurethane foam. The material is sold in the form of mats. Fix with tape. The riser is wrapped in a spiral. Sounds of flowing water with such isolation are almost inaudible.

Box creation

Soundproofing of sewer pipes in a toilet begins with their degreasing. Further stages of work:

- Ground drainage, painting and leak testing.

- Installation of drywall box. On the wall of the bathroom with the help of a building plumb, it is necessary to carry out marking. Pipes should be 5-6 cm from vertical surfaces.

- Fastening profiles. Using a self-tapping screw or dowel, the first element is attached to the wall, and then the second - on an adjacent surface.

- Designation of lines on the floor and ceiling using a square. They should be perpendicular to the profiles.

- On the floor in the center of the intersection of lines make a mark at the installation site of the extreme profile.

- Launch auxiliary elements are laid on the floor along the drawn lines.

- In the center of the intersection of lines set the 3rd profile. The erected frame is fixed with self-tapping screws for metal 9.5 mm long.

- The arranged structure is reinforced with jumpers, between which 45-50 cm are indented.

- Installation of drywall panels. The material must be waterproof. At this stage, in the box you need to create the technological hatch necessary for the inspection and repair of components of plumbing equipment.

- Soundproofing the box - performed after sewing on one side. Between the pipes and the frame, mineral wool is laid, covering it with all the free space.

- Gypsum plasterboard on the 2nd side of the box.

- Facing the resulting structure.

Drywall installation requires careful planning and accurate calculations, so before work it is better to enlist the help of an experienced repairman.

Additional material winding

In addition to creating a soundproofing box, you can achieve winding a fan pipe with certain materials. In this case, use:

- Scissors.

- 12 sheets of damping material on a self-adhesive basis. Each item should have a size of 27x37 cm.

- Soundproofing material. It is better to choose foamed polyethylene.

- Stack roller.

Wrap fan tubes in the following order:

- Degrease the surface of the product.

- Apply damping material over the entire surface of the tube.

- With the help of a roll roller, make a rolling material. At this stage, it is important to remove all air bubbles and firmly glue the surface of the tube with damping material.

- Soundproof by first attaching and cutting the sheet to the size of the tube.

- Glue the cut sheet to vibration damping material, completing the winding of the fan tubes.

The use of wrapping materials allows you to quickly soundproof the drain pipe without involving an assistant.

Use of enclosed soundproof sheath

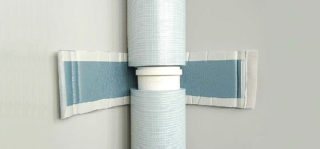

Soundproofing using a closed shell is arranged on the principle of "pipe in pipe". The outer casing is a polyethylene pipe.It is cut into sections convenient for installation and a vertical cut is made to be put on the riser.

The outer pipe when creating sound insulation with a closed shell should have a larger size. For example, if a cast-iron or polypropylene pipe has a size of 110 mm, then for its covering it is necessary to use a product 160x7.7 mm. The resulting volume is filled with a moisture-resistant mineral filler.

Structural Noise Reduction

Structural noise is transmitted along the structural elements of the building. Noise from the source spreads through the slab to the sewer riser, which begins to make rattling and howling sounds.

Structural noise is transmitted along the structural elements of the building. Noise from the source spreads through the slab to the sewer riser, which begins to make rattling and howling sounds.

Structural noise in the riser can be eliminated by installing the pipe correctly. When installing it, it is necessary to use vibration isolation in places where the riser passes through the floor slabs. However, this must be agreed with the neighbors.

Recommendations on choosing a sound insulation method

When choosing a soundproofing method for a sewer riser, first of all, consider the repair budget. Cheaply you can buy rolled materials. The most time-consuming and costly way is to create a protective box that also performs a decorative function.

The fastest and most convenient way to isolate the riser is to use a ready-made soundproof shell. More effort and time will be needed to eliminate structural noise when using sound-absorbing glasses and vibration decouples.