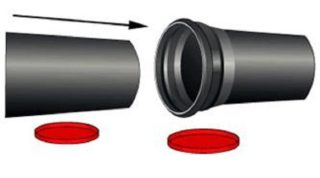

Installation of a sewer collector implies a reliable connection of pipe elements. As a result of the work performed, the system should have excellent tightness. To achieve a tight docking of pipes between each other allows the socket of the sewer pipe. In order to correctly connect the elements in this way, you need special skills and knowledge of collector installation methods.

Definition and purpose of a bell of a sewer pipe

A bell is a special extension from one end of the sewer element. The standard end of the next tube is inserted into it. According to standards, all bell-shaped products have one even cut, and one extended. Thus, all elements are joined sequentially through the bell.

According to the type of manufacturing material, there are several types of products for sewage:

- ceramic;

- cast iron;

- polymer;

- concrete.

Sealing methods for joints depend on the material of the elements used.

The bell performs the following functions:

- allows you to mount the collector without clamps, fittings and other auxiliary parts;

- provides tightness of the system over the entire diameter;

- works as a stiffener when installing an underground outdoor collector;

- simplifies assembly / disassembly of system sections.

Sewer collector with bells lasts 50 years or more without the need for repairs.

Socket sizes

The main dimensions of the polymer pipes for laying the inside of the sewer:

| Pipe section (mm) | Bell inner diameter (mm) | Bell length (mm) |

| 32 | 32,3 | 18 (min) and 24 (max.) |

| 40 | 40,3 | 18 (min) and 26 (max.) |

| 50 | 50,3 | 18 (min) and 28 (max.) |

| 75 | 75,4 | 18 (min) and 33 (max.) |

| 110 | 110,4 | 22 (min) and 36 (max.) |

Methods for installing pipes using sockets

Sewer collector devices with a bell-shaped method are carried out in different ways, depending on the material used for manufacturing the elements used.

Sewer collector devices with a bell-shaped method are carried out in different ways, depending on the material used for manufacturing the elements used.

Installation of PVC or polypropylene system

Two methods are used here - glue / sealant or o-rings. In the first case, the means are applied to the end of the tube inserted into the socket and drive it into the groove to the limit. Previously, the extreme part of the product is slightly treated with emery of a large fraction. The elements collected in the collector are left until the glue / sealant has completely dried (as a rule, the time information is indicated on the instructions for the mixture).

O-rings are used if the product is equipped with a special groove for them. The rubberized element should be uniformly elastic without cracks and tears. The sealant is inserted into the groove, then the end of the next tube is treated with sealant and it is driven into the socket of the previous one until it stops.

Mounting a cast-iron manifold

For metal pipes, two connection methods are also used - chasing and welding. In the first joining method, a special tow and bituminous mastic / cement mortar are used. The installation process looks like this:

For metal pipes, two connection methods are also used - chasing and welding. In the first joining method, a special tow and bituminous mastic / cement mortar are used. The installation process looks like this:

- At the end of the tube inserted into the bell, a mark is made equal to the length of the groove.

- They retreat 1-2 cm from the notch and wrap the product with tow evenly.

- The finished section of the sewer element is driven into the socket until it stops, while simultaneously sealing the winding with a chisel.

- Pour bitumen mastic or cement mortar into the existing slot.

- It remains to wait a day until the solution completely dries. After that, you can use the collector.

Ceramic and asbestos-cement sewer pipes are mounted on the same principle.

Welding of cast-iron pipes is extremely rare, since this equipment requires special equipment. Perform the work in the following sequence:

- The end of the flat tube is driven into the socket until it stops and the gap is filled with cement mixture. It is important to leave at least 1 cm from the end of the funnel.

- After the solution has dried, a special composition for resistance welding is laid in the remaining space and welded to the base of the driven element.

After the welds have cooled, you must immediately check the collector for leaks.

Dismantling the socket element

Repair work of the sewer system is often associated with the need to dismantle its site. Here, they depend on the method of the previously joined tubes:

- When using sealant or glue, it is enough to pull the driven pipe towards you with an effort. She leaves the groove quite easily.

- If chasing was used, it is necessary to cut a piece of the product to the funnel. Then, the remaining segment of the tube with a puncher is marked into four elements and each of them is pulled out with a chisel and a hammer.

When using resistance welding, they act in the same way.