In order for the sewage system to run smoothly, it must be equipped in compliance with sanitary and construction standards. When installing highways in a private house, it is important to consider the distances between the well structures used to check, repair and clean the system.

Types of Sewer Mines

Sewer well constructions are classified depending on their purpose.

- Lookouts. Equipped to control the operation of system elements and to cleanse with the formation of congestion.

- Rotary. They allow you to control the areas through which waste fluids change the direction of advancement, make access to the places of turns and kinks, where blockages are often formed.

- Overflow. They are being built to compensate for the slope of the pipeline, since its increase or decrease leads to the settlement of solid impurities in the pipes.

- Nodal Provide access to connecting pipes.

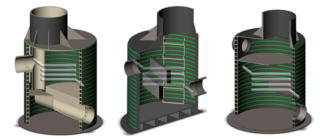

Reinforced concrete is usually used as a material for arranging manholes, but recently plastic tanks are gaining popularity. Any sewer mines are equipped underground. They play the role of connecting elements of the sewer line.

Permissible spacing between wells

The main document determining the design features of wells in the drainage system and the standard distances between them is SNiP 2.04.03-85. It is necessary to adhere to the data indicated in it when laying the sewage line in order to improve the quality of the treatment plants and ensure the correct installation. Subject to the regulations, cracks and leaks do not form in the structures, and sewage liquids move without barriers. Each type of well elements has its own requirements.

Inspection or revision designs

Wells are equipped when installing a pipeline of considerable length, with many turns and bends, where there are branches and transition elements with a change in the pipe section.

The maximum distance between revision installations is determined depending on the section used for the assembly of pipe segments:

- With a trunk diameter of 100 mm, well structures are equipped at least after 15 m.

- If the cross section of the pipes is 150 mm, then the distance increases to 35 m.

- With a pipe size of 200–450 mm, revisions are mounted at a maximum of 50 m from each other.

- Large pipes with a cross section above half a meter assume a distance between revision devices of up to 75 m.

The larger the transverse size of the main pipes, the farther from each other you can equip viewing installations.

Minimum distance between revision sewer wells according to SNIP:

| Cross section (m) | Remote minimum (m) |

| 0,15 | 35 |

| 0,20 – 0,45 | 50 |

| 0,50 – 0,60 | 75 |

| 0,70 – 0,90 | 100 |

| 1,00 – 1,40 | 150 |

| 1,50 – 2,00 | 200 |

| Over 2.00 | 250-300 |

Minimum performance is also important. The abundance of revisions is not good - their number affects the speed of movement of the drain masses. The location of the first audit should be located no closer than three meters from the house, and the permissible maximum removal is no more than twelve meters.

Rotary devices

In terms of their functional and structural features, they are almost similar to revision ones. The only difference between them is that the installation of the turn signal is carried out in places where the pipeline bends.

The distance between the rotary shafts depends on the network configuration.The indicator is calculated based on the length of straight sections between pipe turns. If it goes longer than the norm specified for viewing structures, it will be necessary to install an additional audit so that this sewer section can be controlled.

Overflow wells

If the territory where the sewage system is being set up has a complex relief, differential shafts are used. In hilly areas, the slope of the pipeline will be large. This threatens that the flow rate of wastewater will increase, solid fractions will begin to stick to the inner surface of the pipes and eventually create a cork. Mining shafts reduce the flow rate of drains.

The exact standards for such structures are not calculated, they have other requirements:

- the height indicator of the difference should not be more than three meters;

- at a depth of up to half a meter, the structure can be replaced with a revision with overflow;

- devices are mounted in places of pipe bends.

At the beginning of the line, a tank for washing the network is mounted in the low flow section. It can be a revision or a special device.

Nodal mines

Reservoirs are equipped where supply sewer branches converge into a single drainage line. There are no regulatory requirements for them, except for the section of the mine itself:

| Diameter (mm) | |

| Pipeline | Nodal design |

| 600 | 100 |

| 700 | 1250 |

| 800–1000 | 1500 |

| 1200–2000 | 2000 |

There can be no more than one incoming and three outgoing pipes in the construction tray.

Distance between storm storm water inlets

When creating a storm sewer on a site, it is important to consider the distance between the storm water inlets. It depends on the slope of the tray and the terrain:

| General bias | Maximum distance (m) |

| Up to 0,004 | 50 |

| Up to 0,006 | 60 |

| Up to 0.01 | 70 |

| Up to 0.03 | 80 |

If the territory is wider than 30 m, the distance between the storm water inlets is no more than 60 m. The length from the storm water inlet to the collector revision is a maximum of 40 m, while the installation of no more than one intermediate device is permissible. The cross-section of the connecting section is determined by the calculated inflow of water to the stormwater inlet at a slope of 0.02, but it cannot be less than 20 cm.

How to calculate a suitable distance

In design calculations, the following factors are taken into account when creating a suction line:

- Terrain relief

- characteristic features of the soil;

- the location of aquifers and sanitary protection zones;

- the presence of buildings and communication wiring.

The standards indicate the distance between structures located on direct highways. On pipelines with bends, they can slightly change in the direction of reduction. However, it is impossible to deviate greatly from the requirements, this will worsen the operation of the sewage system.

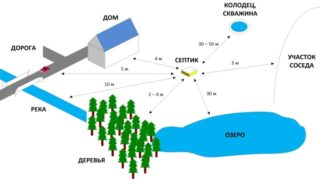

In addition to the distances between the wells, other distances are also taken into account. They are also important for system functioning and security. For example, the distance minimum from any mine sewer to the foundation of the house is three meters, with a maximum of twelve meters.

Leave at least 30 meters between the sewer system and the water supply so that the drains do not pollute the drinking water. The site where the water supply is mounted is located 50 meters or more away from the septic tank.

Compliance with the standards will ensure the smooth operation of the sewer system. If they are ignored, the sewage lines will constantly fail, become clogged, and it will be more difficult to repair and maintain them. Proper installation of well structures will prevent potential troubles and provide access to all elements of the pipeline.