The effective operation of the sewage system depends on the fullness of the cesspool. The correct design guarantees performance without additional maintenance for years. But sooner or later, moments come when the pit begins to fill up quickly. For a short-term solution to the problem, they use the services of wastewater and clean the sewer.

Real difficulties come when filling takes place within a few weeks. Calling cleaning machines and specialists is too expensive, so the root of the problem must be addressed. The following are the main factors that cause a hole to fill up, how to fix the problem, and prevention tips.

Why is the pit filling up fast

A drain pit provides natural drainage of water through the walls and bottom, as well as subsidence inside solids. The deep structure is placed in a dug earthen pit and consists of concrete or brick partitions. At the bottom, an embankment of gravel and large rocks is made to prevent siltation. The location for the location of the pit is chosen so that there is a minimum of groundwater nearby. Otherwise, it is necessary to regularly eliminate the effects of flooding.

A drain pit provides natural drainage of water through the walls and bottom, as well as subsidence inside solids. The deep structure is placed in a dug earthen pit and consists of concrete or brick partitions. At the bottom, an embankment of gravel and large rocks is made to prevent siltation. The location for the location of the pit is chosen so that there is a minimum of groundwater nearby. Otherwise, it is necessary to regularly eliminate the effects of flooding.

The natural functioning of the tank implies a long-term operation of the sewage system without additional intervention. Only occasionally is it necessary to pump out feces and sewage with the help of a sewage machine. The regularity of the procedure is determined by the frequency of use of the sewage system. When the pit begins to clog quickly, the following symptoms appear:

- on the site there is a bad smell and stench, even when the tank is tightly closed;

- water slowly flows into the sewer;

- fatty and fecal deposits appear on the walls of the structure;

- The frequency of calling specialists for pumping increases.

There are five main signs that affect the speed of filling the pit:

- The presence of sludge at the bottom of the structure. The more it is, the worse the natural release of fluid. Sludge needs to be periodically cleaned or chemicals used that aid its decomposition.

- Accumulation of debris and sediment. The more sewage is in the pit, the lower the efficiency of the structure. Periodic cleaning of the bottom and walls is required, including complete washing of the tank.

- Low volume. It is difficult to imagine the level of sewage waste without technical calculations and an engineering project. When determining the volume of capacity by eye or according to the recommendations of friends, people often encounter problems later on.

- Impaired functioning. If intensive groundwater is located under the bottom of the pit, this regularly causes the tank to fill and wet the accumulated sewage. Drainage will not work properly.

- Freezing drains. The most common cause of rapid filling encountered in the winter season. To solve the problem, it is necessary to improve the thermal insulation of the structure.

Methods for solving the problem

The way to fix the problem depends on the cause. The most common case is considered bottom siltation in the warm seasons, which affects the drainage of water. Feces, waste and liquid accumulate faster in the pit, which makes the sewer system less efficient. To solve the problem with sludge, use one of the options described below.

The way to fix the problem depends on the cause. The most common case is considered bottom siltation in the warm seasons, which affects the drainage of water. Feces, waste and liquid accumulate faster in the pit, which makes the sewer system less efficient. To solve the problem with sludge, use one of the options described below.

Technical cleaning. The walls and bottom of the pit become covered with silt over time, despite all the preventive actions.To restore the outflow of water, it is necessary to seek the help of professional scavengers or buy a special pump for self-pumping liquid. A few recommendations:

- Before starting pumping, it is necessary to dilute the contents of the pit, for which ordinary water is poured into it.

- After cleaning the contents, wash the tank. To do this, use water, followed by pumping. The procedure, if necessary, is repeated several times until visually bring the hole in order.

After that, it is necessary to test the operability of the sewage system and take preventive measures to slow down the pollution process. As for the pumped-out sewage, they are placed in a specially dug pit or in a tank, which is then taken away from the site for disposal.

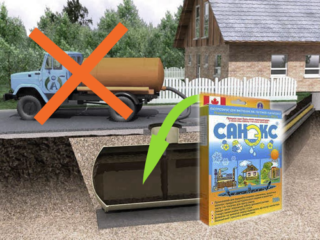

The use of biological products. They are used both to solve the problem of siltation, and to reduce the level of solid waste. The fact is that the biological composition helps to cope with an unpleasant odor and stimulates the process of decomposition of sewage. Due to this, the pit operation efficiency is increased by 70-80%.

The use of biological products. They are used both to solve the problem of siltation, and to reduce the level of solid waste. The fact is that the biological composition helps to cope with an unpleasant odor and stimulates the process of decomposition of sewage. Due to this, the pit operation efficiency is increased by 70-80%.

Biological products perfectly cope with siltation and are a prophylactic. They also prevent flooding of the tank and increase the life of the sewer system without additional intervention. Among the shortcomings, the requirements for temperature are noted - not lower than zero and up to 40 degrees, the need to maintain the level of microorganisms, the negative effect of bleach, washing powders and other detergents.

Chemical substances. Thanks to the chemical compositions, it is possible to cope with the problem of overflow and siltation of the pit, as well as eliminate an unpleasant odor. Unlike biological products, they are resistant to temperature changes and are not applicable only when the tank is frozen.

You should understand the composition of chemicals. Some of them negatively affect the environment, including products with ammonium and formaldehyde. For household use, nitrate oxidizing agents are recommended, which are harmless to living organisms. The product of their oxidation is also used as soil fertilizer.

In the cold season, when the contents of the pit freezes under the influence of low temperatures, it is required defrosting the tank. The problem is often observed in cold regions, as well as with poor thermal insulation of the structure. Frozen sludge reduces drainage efficiency to zero. For prevention, an extension cord of 20-30 meters is needed to get from the nearest outlet to the pit, a copper wire, designed for a power of 2 kW, as well as a metal pin. Step-by-step instructions for defrosting:

- Drive the pin in the center of the frozen waste.

- Fasten the copper wire to the metal base.

- Connect the other end to an electric plug.

- Turn on the voltage.

The rate of thawing depends on the degree of freezing of the waste. If the cold has just arrived, enough days to see the result. When a thick layer of ice has formed, you must wait up to 48 hours. The pit will return to normal, a natural outflow of fluid and the release of the reservoir will begin. After this, the heating element should be removed, having previously turned off the voltage.

Remember about safety measures during the work with electricity. To install, remove the copper conductor is only when the voltage is turned off. If possible, work in rubber boots and special gloves should be carried out.

The solution to other problems is associated with the design features of the tank. If possible, it is necessary to retool, increase the volume or change the location of the pit. Otherwise, you will have to regularly use the services of dumpers.

Measures to prevent this problem in the future

Problems are solved at the design stage, and not as they become available.If obvious errors were discovered as a result of operation, measures should be taken to prevent them in the future.

Problems are solved at the design stage, and not as they become available.If obvious errors were discovered as a result of operation, measures should be taken to prevent them in the future.

- Rinse the pit regularly under high pressure, at least once every two months. The liquid will go into the ground, but will allow it to clear the walls of blockages.

- Use biological products in the warm season to reduce the amount of solid waste. As a result, the pit will become less susceptible to sludge accumulation.

- Timely pumping of the contents is one of the important points, since excessive accumulation of waste contributes to future problems.

- Thermal insulation of a pit or use of a heat-conducting wire. An ideal option is to improve the thermal insulation of the structure. With regular problems with the freezing of waste in winter, you can lay an insulated heat cable in the tank, which will allow heating of frozen waste without additional action.

Alternatively, additional pits are created in the area and connected by pipes. This increases the overall capacity and reduces the number of sewage problems.