Cesspools are usually used for the removal of sewage by owners of country houses. The most common problem is the fast filling of the receiver. Even regular pumping of drains does not save. The problem must be solved, otherwise the sewage system may completely fail.

Why water may not leave

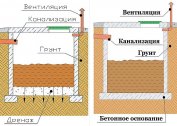

A cesspool is a reservoir that is dug directly in the ground. Usually a layer of rubble, sand or broken brick is laid at the bottom, sometimes the bottom and walls are left unpaved. The principle of operation is the gradual seepage of sewage into the soil through the walls and bottom of the structure. Violation of the absorbent properties of the soil can occur for the following reasons:

A cesspool is a reservoir that is dug directly in the ground. Usually a layer of rubble, sand or broken brick is laid at the bottom, sometimes the bottom and walls are left unpaved. The principle of operation is the gradual seepage of sewage into the soil through the walls and bottom of the structure. Violation of the absorbent properties of the soil can occur for the following reasons:

- Siltation of the bottom - the appearance at the bottom of a layer of fecal sludge, which prevents the passage of water into the ground.

- Grease on the walls and bottom.

- Freezing soil.

- Inadequate receiver volume. Perhaps more people began to use the sewage system, additional devices appeared.

- Low activity of bacteria that can not cope with the processing of organics. This happens for the following reasons: lack of organic substances in the system, too many household chemicals that kill the microflora.

Ways to solve the problem

Flush the system first. To do this, its contents are pumped out and the tank is filled with clean water. After a day, live bacteria are poured. This is necessary to thin the hard crust at the bottom. Microorganisms destroy the sediment, after which the sludge is removed.

Flush the system first. To do this, its contents are pumped out and the tank is filled with clean water. After a day, live bacteria are poured. This is necessary to thin the hard crust at the bottom. Microorganisms destroy the sediment, after which the sludge is removed.

For these purposes, you can use:

- Septic Shock Bioforce. 1 package is designed for 1 m3 the volume of the pit. The cost is about 900 rubles.

- Dr. Robik 509 - 1 bottle per 2 m³ of wastewater. The cost is about 600 rubles.

Important! In the future, fermentation can be supported by Dr. Robik 409. It is added if the temperature of the effluent is above + 4ºС.

Fat Removal

A violation of the filtration abilities of the pit occurs if a large amount of fat and soap foam merge with the drain into it. These compounds clog the soil pores and conduit. The resulting film interferes with the leakage of fluid into the ground. The problem will arise in any case if the system is not equipped with a grease trap.

Soap and fatty compounds eliminate the following drugs:

- Roetech K-87 - the bottle is designed for 1 m³ of waste water.

- Drainage Comfort from BIOFORCE - 1 sachet is poured into 10 liters of water. Used to clean pipes.

- Dr. Robik 809 - eliminates soap formations.

Cleaning takes place in several stages:

- The pit is emptied and pure water is poured into it. Allow to settle so that the chlorine present in the liquid evaporates.

- Preparations in proportion according to the attached instructions are poured through sinks and a toilet bowl.

- Begin operation of the sewer system. Monitor performance metrics. If there is no result, repeat the cleaning.

Biological products help eliminate deposits in the pipeline and continue to operate in the tank. Bacteria that break down fat and soap formations are systematically introduced into the pit.

Discharge of clarified wastewater

In case of insufficient capacity of the existing tank, radical measures are necessary:

In case of insufficient capacity of the existing tank, radical measures are necessary:

- the device is more capacious pit;

- connection to an additional capacity system;

- installation of a drainage well or a filtration field device.

In the latter case, the pit is being modernized into a septic tank.

Drainage well

For the installation of a filtration well, it is necessary to dig a mine with a depth of about 4 m, until a sand layer appears. The structure is constructed without a bottom and / or with perforated walls. A layer of crushed stone 20-30 cm thick is laid at the bottom.Walls can be made of any improvised materials: tires, bricks, reinforced concrete rings.

The pit and the filter well are connected using a pipe with a diameter of 110 mm with a slope of 2 cm per 1 m of pipe. The result is a design in which the first chamber is necessary for mechanical cleaning (heavy particles settle on the bottom), and in the second, the liquid is clarified and drained into the soil.

Filtration field

The construction of the filtration field requires a large area of the site. The design consists of pipes with perforations dug in the ground. First, a layer of earth is removed 1-1.5 m deep, a layer of sand and gravel is poured (25 cm). Pipes are mounted on top of the pillow and again covered with crushed stone and sandstone mixture. Cover with a layer of soil.

To filter the effluents produced by 1 person, you will need 8 m of pipes. Drainage fields require a large area, to reduce it, pipes are mounted in parallel. For the free movement of drains, observe a slope of 25 mm per 1 line. m

Thermal insulation measures

Freezing of the pit occurs if the owner neglected the requirements for deepening the tank below the level of freezing of the soil. To prevent freezing of pipes, they should be insulated based on local weather conditions.

Freezing of the pit occurs if the owner neglected the requirements for deepening the tank below the level of freezing of the soil. To prevent freezing of pipes, they should be insulated based on local weather conditions.

If the system freezes, the consequences are eliminated in the following ways:

- steam generator;

- thermal insulation work after heating;

- installation of a heating cable.

Important! A common method with pouring boiling water into the pipes causes the return of feces and an unpleasant smell from the pit. Then you have to collect fecal matter and flush the pipes. The best option is to use a steam generator to warm up.

If the ice crust is present only on the surface of the pit, the following actions must be performed:

- make several holes;

- heat the ice with a steam generator;

- pump out waste water;

- pour boiling water to eliminate the remnants of ice.

When the temperature of the system reaches + 30ºС, Dr. Robik 509 or Septic Shock Bioforce biological products are added to the pit to activate the fermentation process.

To prevent such situations in the warm season, it is necessary to carry out insulation. In winter, you can also prevent a similar situation. Near the pit, a fire is made to warm the earth. Expanded clay is also spread on burning coals. When the firewood goes out, the septic tank is surrounded by foam. It is mounted on the ground around the pit in 2 layers, and the diameter of the blind area should be equal to the depth of the pit.

The pipeline is sheathed with thermally insulating covers. The best option to prevent freezing is to use a heating cable that works from the network. Depending on the modification and purpose, it is laid directly in the pipe or outside.

Important! To connect various metal pins clogged into the soil to the power grid to warm the ground is life threatening.

Problem Prevention

To prevent the rapid filling of the pit, it is necessary to observe a number of rules during operation:

- Timely pump sewage out of the pit. Especially when preserving the system for the winter.

- Systematically flush the walls and bottom of the pit. It is enough to do this once a year.

- To eliminate odor and soap film, bacteria or chemicals should be regularly poured into the pit in the warm season.

- Even at the time of installation of the sewer pit, it is necessary to take into account the depth of freezing of the soil. If necessary, the tank is additionally insulated.

Compliance with these simple measures will ensure reliable uninterrupted operation of the sewer system for many years.