When installing stormwater / domestic / industrial sewage, the use of polymer wells for sewage is widespread. Such tanks differ in technical characteristics from the usual reinforced concrete structures, in most cases for the better.

Advantages and disadvantages of plastic wells for sewage

Experts highlight the following positive aspects of polymer tanks:

- The smoothness of the inner walls of the wells, due to which it is possible to prevent siltation of the system, subsidence of sand and earth on its walls.

- The accuracy of geometric connections (nozzles, caps, bottom). Prevents the possibility of leakage into the ground. All joints are reinforced with factory rubberized gaskets, so an environmental disaster on the site is excluded.

- Polymer strength. Designs withstand pressure / swelling of soil, static and dynamic loads due to the corrugated body of the product. Corrugation rings act as stiffeners.

- Ability to touch tanks in height using separate screw-on elements.

- Light weight of products, which facilitates their transportation and subsequent installation. One unit a meter high has a mass of up to 50 kg.

- Low thermal conductivity.

- Resistance to temperature differences.

- Inertness to aggressive environments.

- Availability. The average price of one well is about 5-7 thousand rubles.

The disadvantages of polymer products include the need to use sealant when connecting them to the system nozzles. At the same time, auxiliary components provide greater reliability of stormwater. In addition, despite the strength of the tanks, their installation must be carried out according to the instructions. Otherwise, there is a risk of damage to the integrity of the mine.

Materials used

Tanks are made of three types of polymers:

- PVC It is marked as PVC. Polyvinyl chloride is considered the most durable and resistant to aggressive environments. Such wells are used for sewage devices in industrial enterprises. Resistant to burning.

- PE. It is marked as PE. The use of polyethylene sewer wells is common on moving soils and at low temperatures. Resistant to repeated freezing / freezing without loss of ductility.

- Polypropylene (PP). Plastic and wear-resistant material that becomes brittle upon freezing. However, if we take a polymer-sand receiver, in which fine sand plays the role of reinforcement, the tank will become several times stronger even under subzero temperatures.

Sizes of plastic wells for sewage: diameter varies in the range of 3000-1000 mm; height - within 1-1.5 m; tank wall thickness - from 10 mm.

Scope of application

Plastic wells can be used as standalone tanks for the network and as airtight inserts in concrete shafts. In this case, the tightness of the receivers increases, and the ground pressure on them does not have such a negative effect.

The main purpose of polymer wells is to connect the branches of one highway to ensure the smooth operation of the system. In general, polymer tanks perform several functions at once:

- work as points of change in the direction of the pipeline;

- provide reliable monitoring of the entire communication;

- allow you to lay pipes at different levels relative to the horizontal, subject to complex terrain;

- help change the speed of the transported stream;

- provide access to sewage areas for repairs.

Polymer wells are mainly used for the installation of domestic and industrial collectors, as well as for the installation of a reliable central stormwater or drainage system on the site. Occasionally, tanks are used for cable communications in order to check their condition.

Types and arrangement of plastic wells

All polymer tanks are divided into several types according to their intended purpose. Most Popular:

- Revision (inspection). Allow you to evaluate the status and performance of the system. Structurally, they consist of a plastic shaft, a perforated bottom and a screw cap. If necessary, have openings in the lower part for supplying the pipeline to them.

- Overflow. They provide pipe laying at different levels. They can work as rotary to change the direction of flow. The design of such tanks is a shaft, a lid and a sealed bottom.

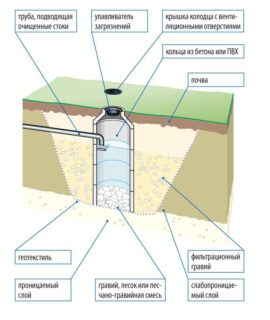

- Absorption (drainage). Designed to drain accumulated moisture into the ground. They do not have a bottom, but are equipped with a polymer shaft and a lid. The bottom in this case is arranged from river sand, gravel of a fine fraction, broken slag or brick.

- Cumulative. Fully sealed tanks for collecting water. In the future, it can be used for economic or technical purposes. Typically, a storage receiver is installed at the lowest point of the system.

- Overflow

- Turning

- Cumulative

In most cases, installation of a trunk with a total length of 30 meters or more will require at least two or three different polymer tanks (absorption or storage, revision, swivel).

Installation Principles

Installation of polymer receivers is carried out in several stages. At the same time, depending on the type of reservoir, the sequence of actions is supplemented or shortened. Work Stages:

- Preparation of the pit. Depth is 20-30 cm higher than the height of the tank. In turn, the diameter of the pit must be increased by 20 cm from the existing section of the well. This distance will later go to a powerful dusting.

- Foundation preparation. Actions vary depending on the type of receiver. Under the storage well, you need to compact the soil, add a 15 cm thick sand cushion and compact it well, pour a layer of concrete mortar on top. After it hardens, you can put the receiver. If the well is absorbent, first install the tank, then pour a layer of river sand, fine gravel and crushed brick on top of it.

- Pipe connection. Before installing the receiver in the pit, holes are formed in it for the input of the trunk. They connect the pipes, the joints are sealed with a rubber gasket. Additionally, you can use sealant. They process a sealing cuff around the entire perimeter.

- Backfilling of the well. So that the compacted soil does not deform the tank around the perimeter, it must first be filled with water. After that, earth is poured around the well and carefully tamped with layers.

The last stage of the installation of wells is the installation of a manhole cover. It is freely mounted in technical grooves.

If the tanks are installed on a public highway, it is advisable to provide a locking mechanism for the well cover.

Prices for polymer tanks for sewage

The prices of plastic wells for sewerage vary slightly depending on the models, dimensions, material. Approximate cost of tanks in Moscow:

- distribution well - from 6 to 14 thousand rubles (depending on size);

- viewing - from 3.5 to 15 thousand rubles;

- prefabricated receivers, consisting of individual (retouched) elements - from 8 to 12 thousand rubles.

You can buy individual components for the system.A screw-on ring to increase the height of the tank, a manhole cover or a bottom to be touched will cost between 2.5-5 thousand rubles.