Sand traps are part of storm sewers. These engineering tools are used to delay sand and small fractions of debris from entering the network. They are also installed to collect surface effluents at industrial enterprises with a drain into the internal sewage system and car washes.

Structure and principle of operation

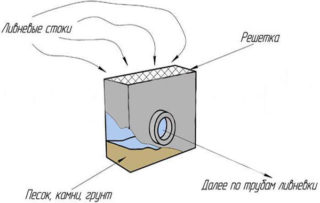

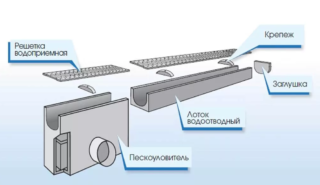

The sand trap is produced in the form of a container with side pipes located above the bottom and the upper compartment - a water receiver. Between it and the bottom there is a special lattice that cuts off dirt, sand and silt from the water runoff.

The principle of operation of the device:

- Surface runoff is routed to the intake trays and drains due to the created slope in the sand trap.

- The device has a large volume, so the flow rate decreases sharply. This leads to the precipitation of particles of debris and grains of sand.

- Water masses move further along the collector, gaining speed.

Sand traps are also placed in the border zone at the same time several drains moving in different directions.

Sand traps are equipped with special chambers - galvanized steel baskets. Fragments of garbage get into them. Devices with similar baskets are easier to clean.

Types of sand traps

For different types of sewer networks, structurally different sand traps are used. They can be single-section or have several compartments depending on the purpose and amount of surface water.

The most commonly used sand trap options are:

- Vertical, cylindrical in shape. The solid sediment will settle on its own to the bottom of the large tank, and the purified liquid will begin to flow out through the outlet pipe. They are usually used at industrial facilities.

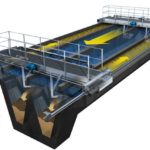

- Horizontal Structurally the simplest, but clean thoroughly. Consist of two compartments. In the first, the water stream moves either directly or in a circle. In the second, precipitation occurs. Ideal for home use.

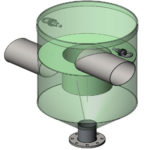

- Tangential. Round-shaped devices, water flows in them fall tangentially. Thanks to the centrifugal force, the water flow in the tank starts to rotate, and fragments of garbage are knocked out on its walls and slowly slide on the bottom of the device.

- Tangential sand trap

- Vertical construction

- Horizontal sand trap

The latter option is more expensive than the previous ones and, despite its effectiveness, is not often used.

Materials of manufacture

Engineering devices for collecting dirt are made from the following materials:

- concrete;

- polymer concrete;

- plastic;

- stainless steel.

Concrete options are strong and stable, but they weigh a lot, which complicates the installation. Over time, under the influence of water, they go through small cracks and lose their tightness. Their cost starts from 3000 rubles.

Plastic installations are inexpensive: the price starts from 1000 rubles. Other advantages are light weight, ease of installation, corrosion resistance, tightness, resistance to temperature changes.

Polymer concrete devices combine the advantages of concrete and plastic structures. They are strong, but they do not weigh much. Such products cost more than the previous ones - from 5000 rubles.

Stainless steel options are usually installed in factories. Sometimes they are equipped with aerators for more effective cleaning, especially from oily and viscous suspensions. The minimum price of a stainless steel sand trap for domestic sewage is 15,000 rubles.

Mounting Features

Proper installation of the sand trap is the key to a long and efficient operation of the device. Mounting the structure is easy if you use the step by step instructions:

Proper installation of the sand trap is the key to a long and efficient operation of the device. Mounting the structure is easy if you use the step by step instructions:

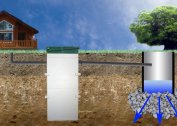

- Mark the territory for storm sewers. The site selected for the sand trap is located near the gutter before entering the main system.

- They dig a pit, the volume of which is slightly larger than the sand tank.

- Concrete the bottom of the pit to subsequently avoid skewing of the sand trap.

- Install a sand trap on concrete and fix it with special bolts.

- Connect the structure with the help of pipes with a sewer line and a spillway and dig a pit.

The operation of the device is achieved through proper installation. The water inlet hole is located above the outgoing one. This difference in height allows the water stream to move through a sand trap, to the bottom of which sediment fragments and sand grains precipitate. When installing a sand trap, a slope of 10 mm per meter of the drain pan must be ensured, otherwise the system will not function.

A sand trap is an important part of storm sewers. If the device is neglected, blockages will often appear in the system, which will significantly reduce its effectiveness and operational life.